A flexible Hooker hinge

A Hookee hinge and flexible technology, applied in the direction of elastic couplings, program control manipulators, manipulators, etc., can solve the problems of unfavorable structure for long-term use, poor hinge dynamic performance, unfavorable miniaturization manufacturing, etc., to achieve novel overall structure, Convenient processing and assembly, excellent mechanical and dynamic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

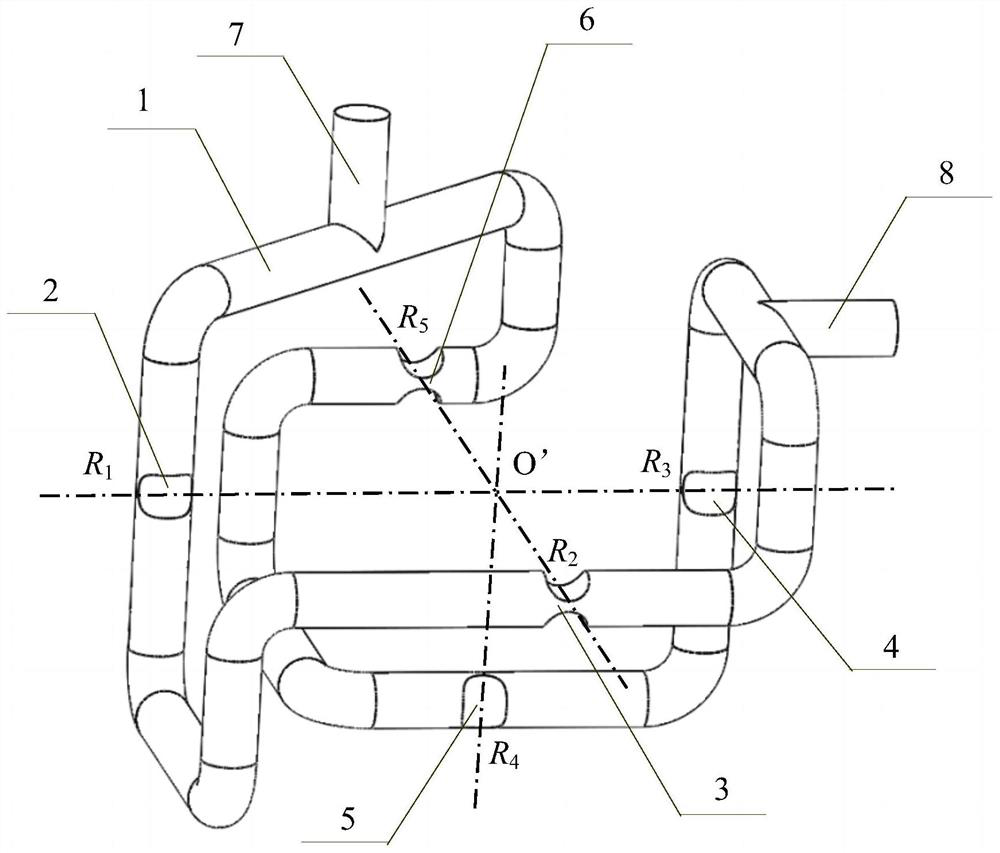

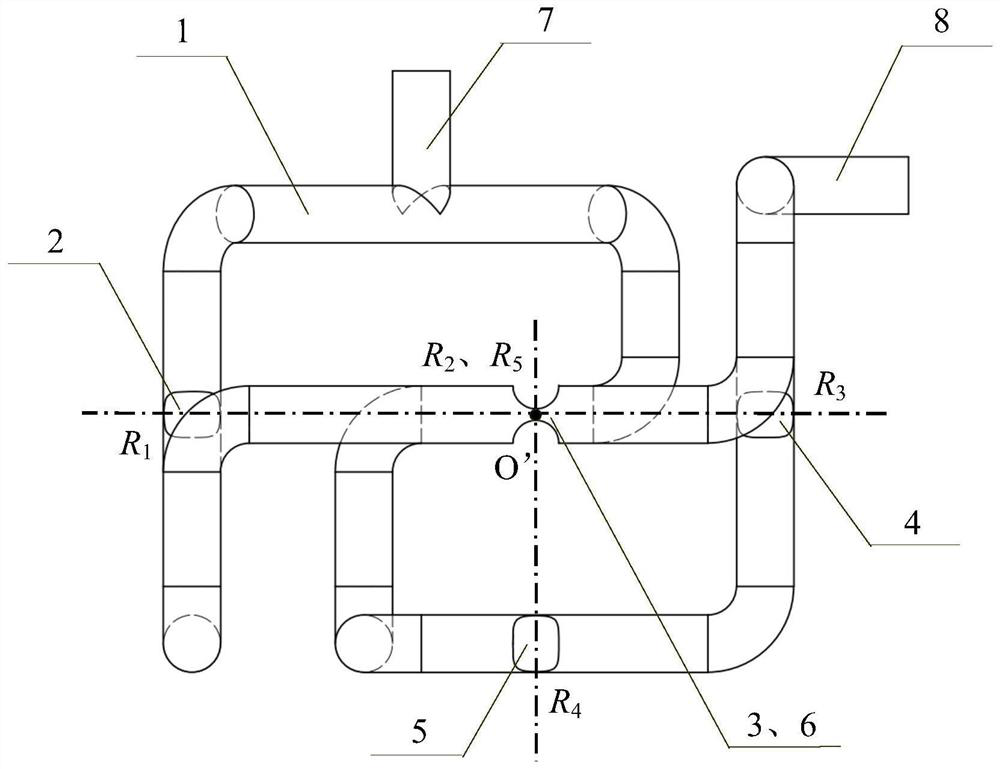

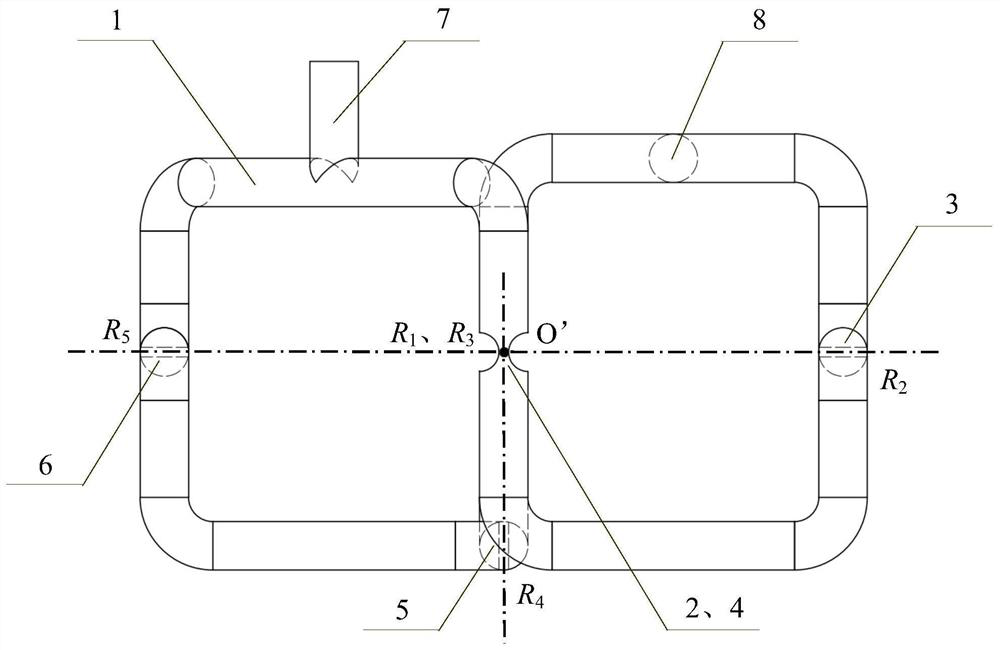

[0040] Such as Figure 1 to Figure 4 As shown, a flexible Hooke hinge includes a hinge body 1 and a first connecting shaft 7 and a second connecting shaft 8 vertically installed on the hinge body 1 . The hinge main body 1 is an integrated structure, which is formed by bending a cylindrical shaft with five sets of arc-shaped cutouts 9 at 13 right angles (ie 90°). Specifically, the hinge body 1 is a closed structure formed by connecting a cylindrical shaft end to end, and the cylindrical shaft is bent 13 times at 90° to form 13 right-angle structures; five groups of arc-shaped cutouts 9 are made on the bent cylindrical shaft , and each group contains two arc-shaped cutouts 9 distributed in mirror symmetry.

[0041] Such as Figure 8 As shown, a cylindrical shaft is divided into 13 cylindrical segments, and the 13 segments are marked as ①, ②, ③, ④, ⑤, ⑥, ⑦, ⑧, ⑨, ⑩, The two segments are connected by curved shaft segments bent into arcs to form a right-angle structure, and t...

Embodiment 2

[0068] The difference between this embodiment and Embodiment 1 is that the hinge body 1 is a closed structure consisting of 13 cylindrical shafts sequentially connected through arc-shaped elbows to form a closed end-to-end structure, and two adjacent cylindrical shafts are connected through arc-shaped elbows At right angles to the structure. Such as Figure 8 As shown, in the cylindrical axis ②, ⑤, ⑧, ⑨, A group of arc-shaped cutouts 9 are respectively provided on the top, which are the first flexible rotating pair 2, the second flexible rotating pair 3, the third flexible rotating pair 4, the fourth flexible rotating pair 5 and the fifth flexible rotating pair 6, each group There are two arc-shaped cutouts 9, which are symmetrically distributed as mirror images.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com