Transmission mechanism for electric tool with axial locking function

A technology of transmission mechanism and power tool, which is applied in the direction of manufacturing tools, transmission devices, gear transmission devices, etc., can solve the problem that the locking structure cannot move stably to the locked position, the axial locking device is unstable, and the power tool is slipping when used. problems, to avoid the failure of the shaft lock, increase the torque, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

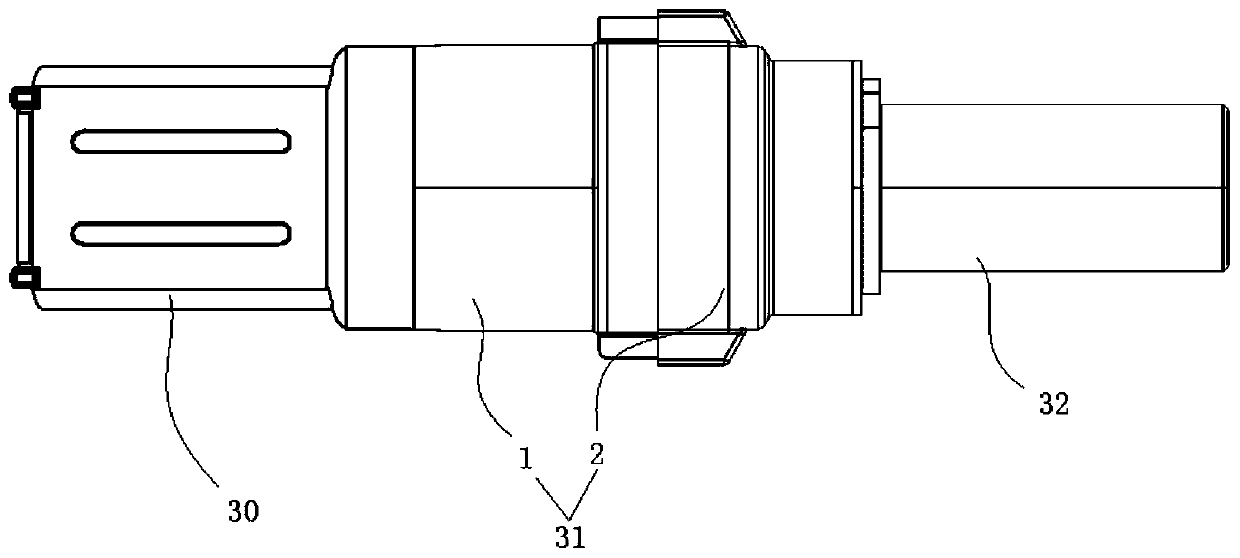

[0044] An electric tool transmission mechanism with a shaft lock function in this embodiment includes a motor 30, a transmission mechanism 31 and an output spindle 32;

[0045] The motor: connected to the transmission mechanism for power output;

[0046] The transmission mechanism: it is composed of a reduction gear box and an axial locking device. The reduction gear box is a planetary gear reduction box, which is used for receiving and transmitting power, and can be self-locking;

[0047]The output spindle: connected to the axial locking device, receives the power transmitted by the axial locking device, and is used to connect the electric tool head and perform output work;

[0048] Wherein, the reduction gear box is connected with the motor transmission, receives the power input by the motor, and outputs to the axial locking device after gear transmission and increased torque; the axial locking device receives the power transmitted by the reduction gear box , and drive to t...

Embodiment 2

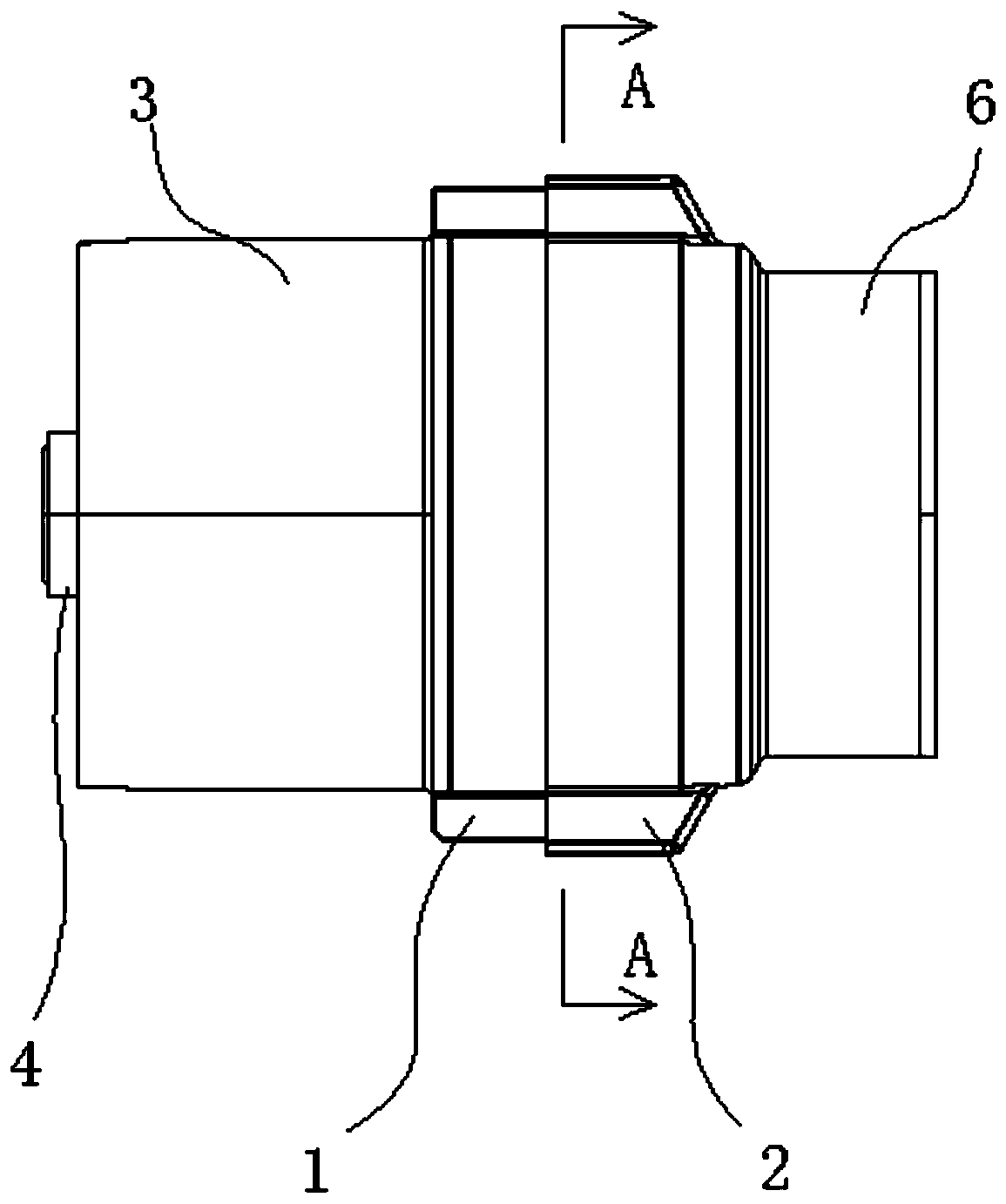

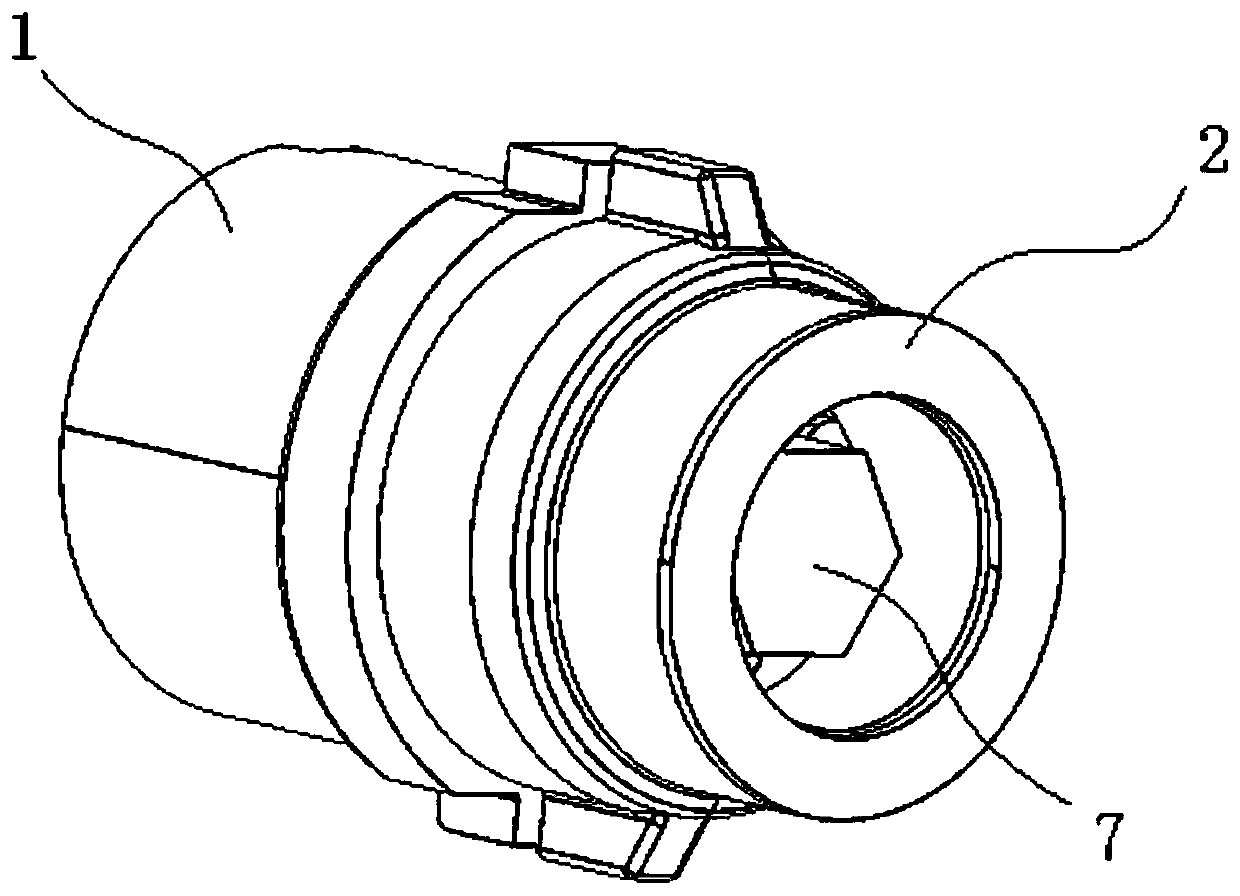

[0050] An electric tool transmission mechanism with a shaft lock function in this embodiment, wherein the reduction gear box 1 includes a speed change inner tooth sleeve 3, an input gear 4 and a transmission planetary gear 5, and the axial locking device 2 includes a shaft Lock protection sleeve 6, shaft lock cam 7, shaft lock pin 8 and shaft lock middle piece 9;

[0051] The variable speed inner gear sleeve 3 is in the shape of a cylindrical tube sleeve, and its inner wall is provided with a ring of internal gear openings 10 distributed in a circle. One end of the variable speed inner gear sleeve 3 is clamped with a limit buckle 11, and the other end is locked with the shaft. The protective sleeve 6 is fixedly connected, and the transmission planetary gear 5 is arranged in the speed change inner gear sleeve 3, including a gear plate 12 and a first transmission gear 13. The gear plate 12 is disc-shaped, and a first rotating shaft is provided on one side 14, the other side is p...

Embodiment 3

[0056] A power tool transmission mechanism with a shaft lock function in this embodiment, wherein the number of the transmission planetary gears 5 is multiple, and a plurality of transmission planetary gears 5 constitute a transmission planetary gear set 24, and the adjacent transmission planetary gears 5 The first transmission gear 13 of the first transmission gear 13 meshes with the transmission rotary gear 15, and the transmission planetary gear 5 at one end of the transmission planetary gear set 24 meshes with the input gear 4 through the first transmission gear 13, and the other end of the transmission planetary gear set 24 meshes with the second transmission gear 171 through the transmission rotary gear 15. The inside meshes to realize the transmission;

[0057] In this embodiment, the number of transmission planetary gears in the reduction gearbox can be increased as required to achieve greater torque output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com