Aging sensor based on conductive composite material and manufacturing method of aging sensor

The technology of a conductive composite material and a manufacturing method, applied in the field of sensors, can solve the problems of high monitoring cost, inability to realize real-time in-situ monitoring, time-consuming and labor-intensive, etc., and achieve the effect of reducing monitoring investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

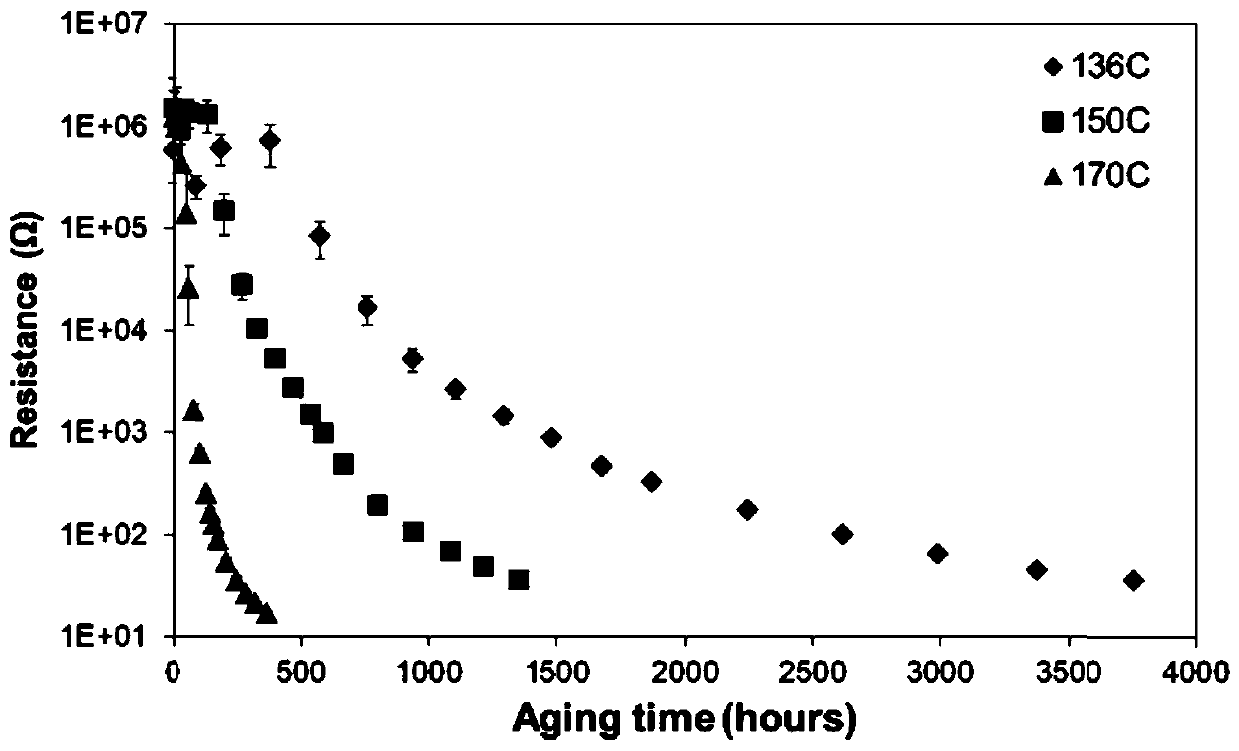

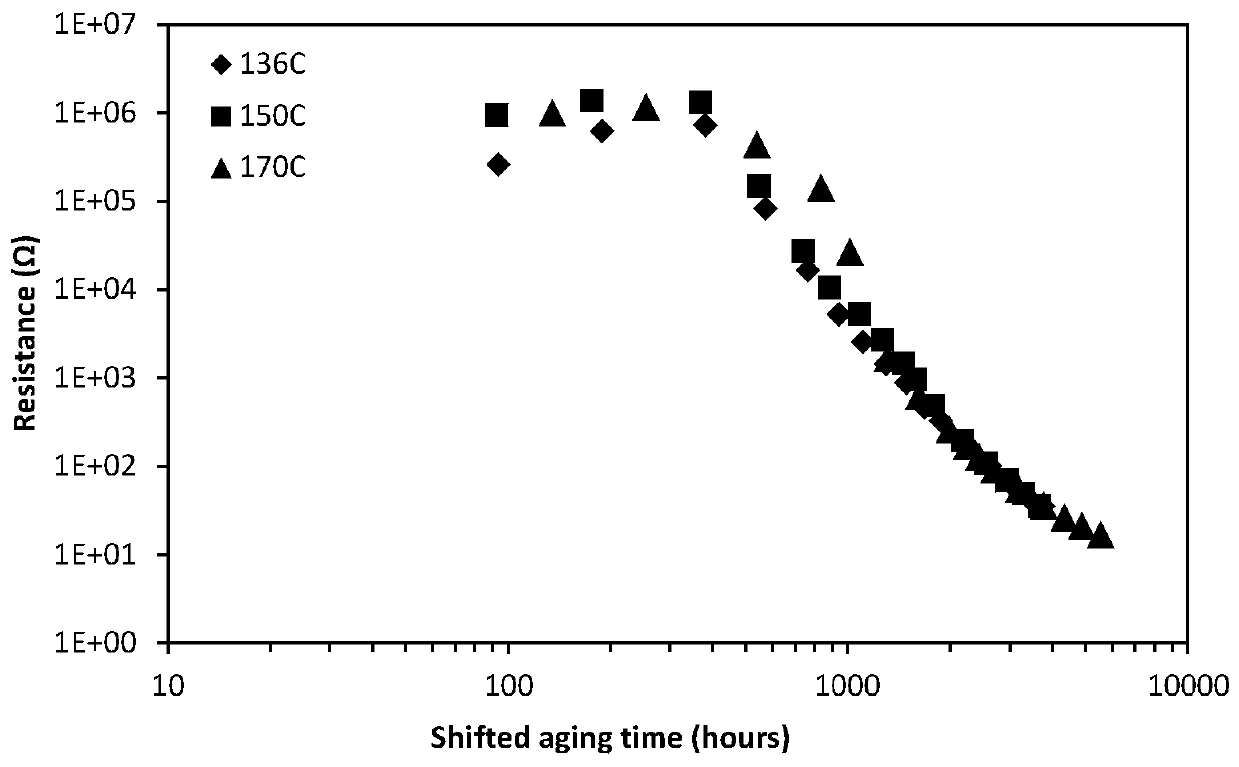

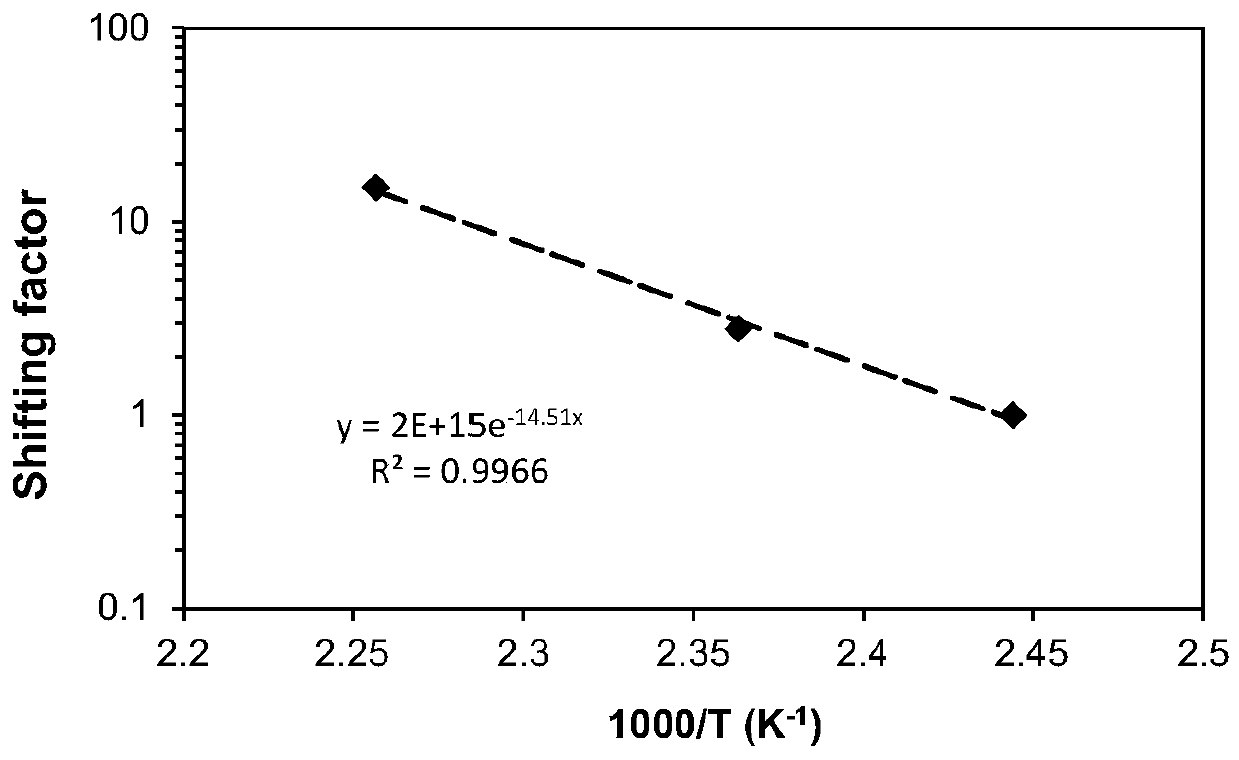

[0055] An EPDM resin for wire and cable was chosen as the polymer matrix for sensor fabrication. Antioxidants are removed from virgin EPDM resins, eliminating the latent period of aging. Carbot XC-72 carbon black was used as a conductive filler with a filler content of 35wt.%. Dicumyl peroxide is a crosslinking agent, and its content is between 1wt% and 2wt%. The filler and polymer matrix are mixed in a three-roll mill. In order to obtain the best dispersion effect of the filler, it needs to be mixed and stirred 100 times. The resulting homogeneous mixture was transferred into a Teflon mold, and the resulting EPDM composite was cured by hot pressing at 150 °C for 1 hour. The sample thickness was kept at about 300 μm to mitigate diffusion limited oxidation effects. The sensor was tested at three different aging temperatures to monitor its resistivity and tensile elongation at break as a function of aging time.

[0056] For the convenience of the product aging test, no anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com