Oxygen control preparation method and screening device for sintered NdFeB permanent magnet

A screening device and permanent magnet technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve problems such as the uniformity of oxygen content in NdFeB magnetic powder, and the difficulty in achieving consistent oxygen content , to achieve the effect of weakening the uneven oxidation reaction, facilitating long-term storage and reducing the degree of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

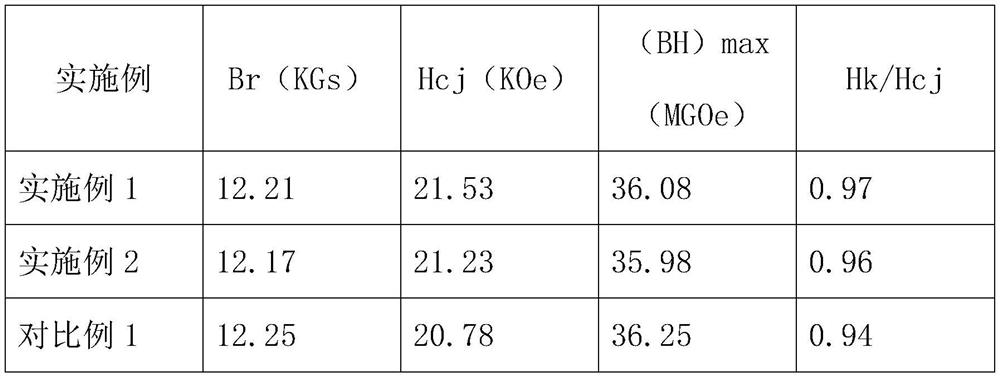

Embodiment 1

[0024] (1) Ingredients: The mass percentage of raw materials is: PrNd: 29%, Ho: 4%, B: 0.94%, Al: 0.9%, Cu: 0.2%, Co: 0.2%, Ga: 0.1%, Zr: 0.1% , the balance is Fe;

[0025] (2) Melting: first put the raw materials into the crucible of the quick-setting furnace for melting, then evacuate the quick-setting furnace to below 1Pa, and start to bake the material. The power of the baking material is set to 100KW, and the material is baked for 20 minutes. , fill with argon to -0.065Mpa, then increase the power to 500KW, start smelting for 10 minutes, adjust the smelting power to 360KW, and carry out refining. The refining time is 5 minutes; when the alloy liquid surface turns silvery white, start casting. piece;

[0026] (3) Hydrogen crushing: put the cast piece into a hydrogen crushing furnace to absorb hydrogen to saturation, then heat to 600°C to dehydrogenate below 20Pa to obtain coarse powder;

[0027] (4) Preparation of fine powder: add 0.1% antioxidant to the coarse powder, f...

Embodiment 2

[0033] (1) Ingredients: The mass percentage of raw materials is: PrNd: 29%, Ho: 4%, B: 0.94%, Al: 0.9%, Cu: 0.2%, Co: 0.2%, Ga: 0.1%, Zr: 0.1% , the balance is Fe;

[0034] (2) Melting: first put the raw materials into the crucible of the quick-setting furnace for melting, then evacuate the quick-setting furnace to below 1Pa, and start to bake the material. The power of the baking material is set to 100KW, and the material is baked for 20 minutes. , fill with argon to -0.065Mpa, then increase the power to 500KW, start smelting for 10 minutes, adjust the smelting power to 360KW, and carry out refining. The refining time is 5 minutes; when the alloy liquid surface turns silvery white, start casting. piece;

[0035] (3) Hydrogen crushing: put the cast piece into a hydrogen crushing furnace to absorb hydrogen to saturation, then heat to 600°C to dehydrogenate below 20Pa to obtain coarse powder;

[0036] (4) Preparation of fine powder: add 0.1% antioxidant to the coarse powder, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com