Square battery fixing structure and using method thereof

A fixed structure, square battery technology, applied in the direction of structural parts, battery pack parts, circuits, etc., can solve the problems of battery installation accuracy requirements, insufficient precision of sheet metal shells, tolerance accumulation, etc., to achieve enhanced strength, mechanical High machining accuracy, reducing the effect of matching surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

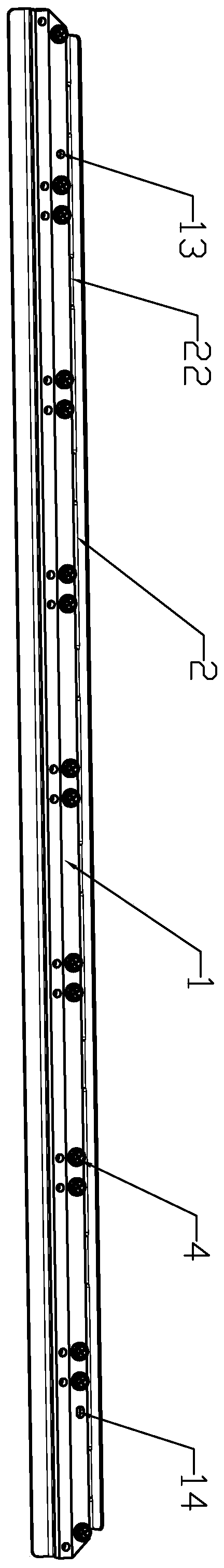

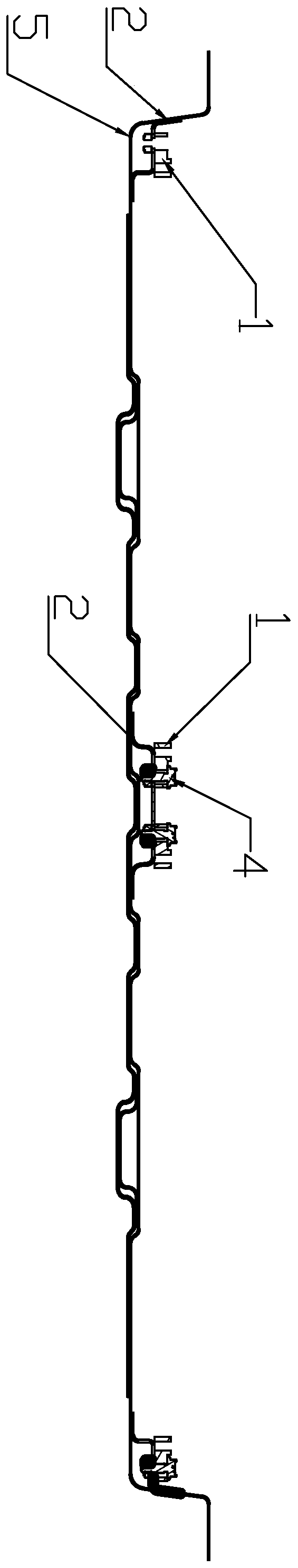

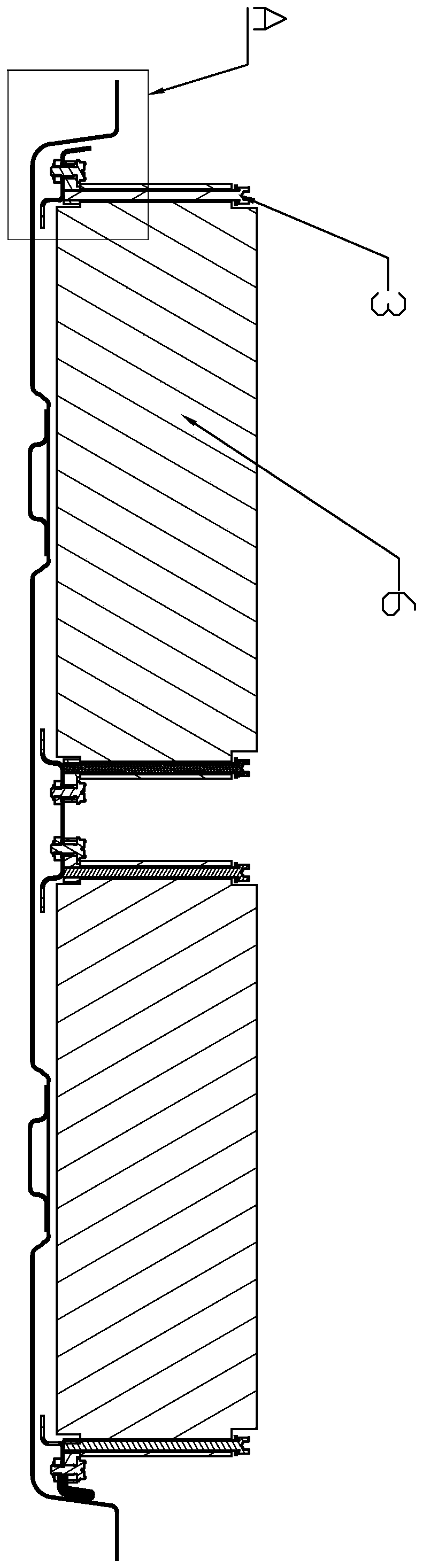

[0041] Such as figure 1 , figure 2 In the shown embodiment 1, a square battery fixing structure includes a first fixing part 1 made of an aluminum alloy profile and a second fixing part 2 of a sheet metal part. The long bolt 3 of the fixing part and the short bolt 4 of the short fixing part. Such as Figure 4 As shown, the cross-section of the first fixing member 1 is L-shaped horizontally, including two stepped structures, wherein the higher stepped structure is the battery matching part, and the shape of the battery matching part is adapted to the shape of the bottom installation structure of the battery module 6, and the battery A number of battery module installation holes 11 are longitudinally opened on the matching part, and the holes are screw holes, which are adapted to the long bolts 3; the lower step structure is the fixing part, and the fixing part is longitudinally opened with a through hole with a diameter larger than the short bolt 4 12. The second fixing pa...

Embodiment 2

[0044] Such as Figure 5 In the shown embodiment 2, a square battery fixing structure includes a first fixing part 1 made of aluminum alloy profiles, a second fixing part 2 of a sheet metal part, long bolts 3 , short bolts 4 and shock absorbing parts 15 . Its structure is roughly the same as that of Embodiment 1, the difference is that two card slots 16 are opened on the first fixing member 1, and the card slots 16 are located on both sides of the battery module installation hole 11, and the card slots 16 are carded with long Bar-shaped rubber shock absorber 15, such as Figure 6 As shown, the section of the shock absorber 15 is T-shaped, and includes an upper horizontal shock absorbing portion 151 and a lower longitudinal snap-in portion 152. Both sides of the snap-in portion 152 are convex arc surfaces, and the snap-in portion 152 snaps When in the draw-in groove 16, the arc surface is pressed inwards to withstand the draw-in groove 16 groove walls. Such as Figure 7 As s...

Embodiment 3

[0047] A method for using a square battery fixing structure. First, the second fixing member is spot-welded in the battery lower case 5, wherein the two sides are welded to the battery lower case 5 through the side connection part and the bottom connection part, and the second fixing part in the middle is welded to the battery lower case 5. 2. The fixing part is welded with the lower case of the battery through the bottom connecting part;

[0048] Use tooling to place the four first fixing parts in parallel and position them on the second fixing part. Firstly, the positioning pins are inserted into the main positioning hole, the auxiliary positioning hole and the positioning via holes for positioning, and then the first fixing parts are fixed on the second fixing part through short bolts. Two fixing parts, such as figure 2 shown;

[0049] Manually install the individual battery modules on the first fixing part in sequence through long bolts, and after the two rows are assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com