Metering valve for controlling a gaseous medium

A technology for gaseous media and metering valves, which is applied in the direction of lift valves, valve details, valve devices, etc., can solve the problems of proportional valve sealing performance, angle tolerance, etc., to ensure high sealing performance, improved sealing performance, and small pressure fluctuations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

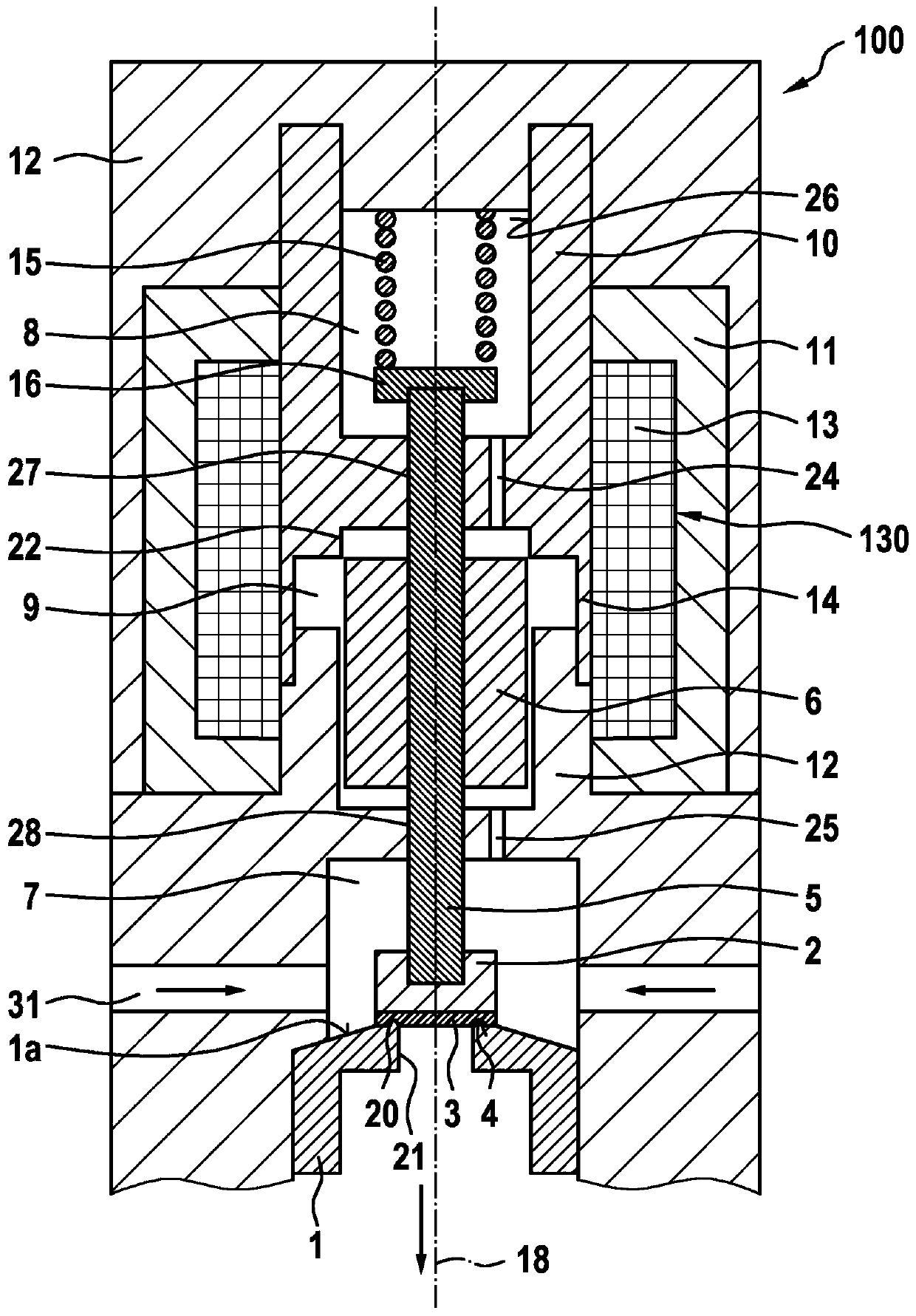

[0016] figure 1 An exemplary embodiment of a metering valve 100 according to the invention is shown in longitudinal section. The metering valve 100 has a valve housing 12 in which an inner chamber 26 is formed. An electromagnet 130 comprising a solenoid coil 13 , an inner pole 10 and an outer pole 11 is arranged in the inner chamber 26 . In this case, the inner pole 10 is connected to the valve housing 12 via a spacer bushing element 14 made of a non-magnetic material.

[0017] Furthermore, in the armature chamber 9 contained in the inner chamber 12 there is an armature 6 which is movable back and forth with a rod-shaped element 5 , wherein the rod-shaped element 5 is fixedly connected to the electromagnetic armature 6 and not only the notch 27 of the inner pole 10 and is received and guided in the notch 28 of the valve housing 12 . The armature 6 is designed as a plug-in armature and is received in a recess 22 of the inner pole 10 during its stroke movement.

[0018] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com