Bracket cleaning device for production of LED lamps

A technology of LED lamps and cleaning devices, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as time-consuming, inability to remove the bracket, and low cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

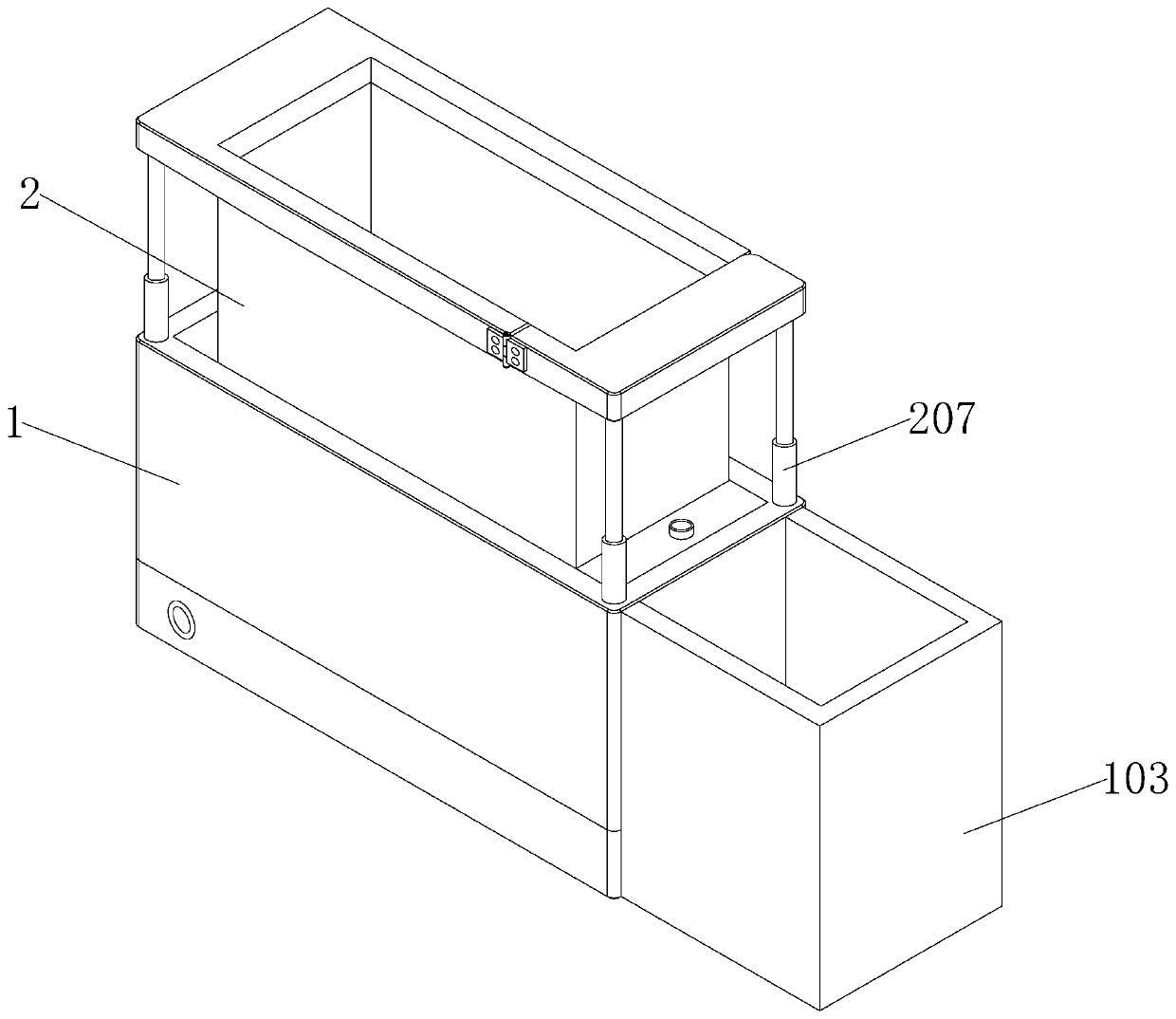

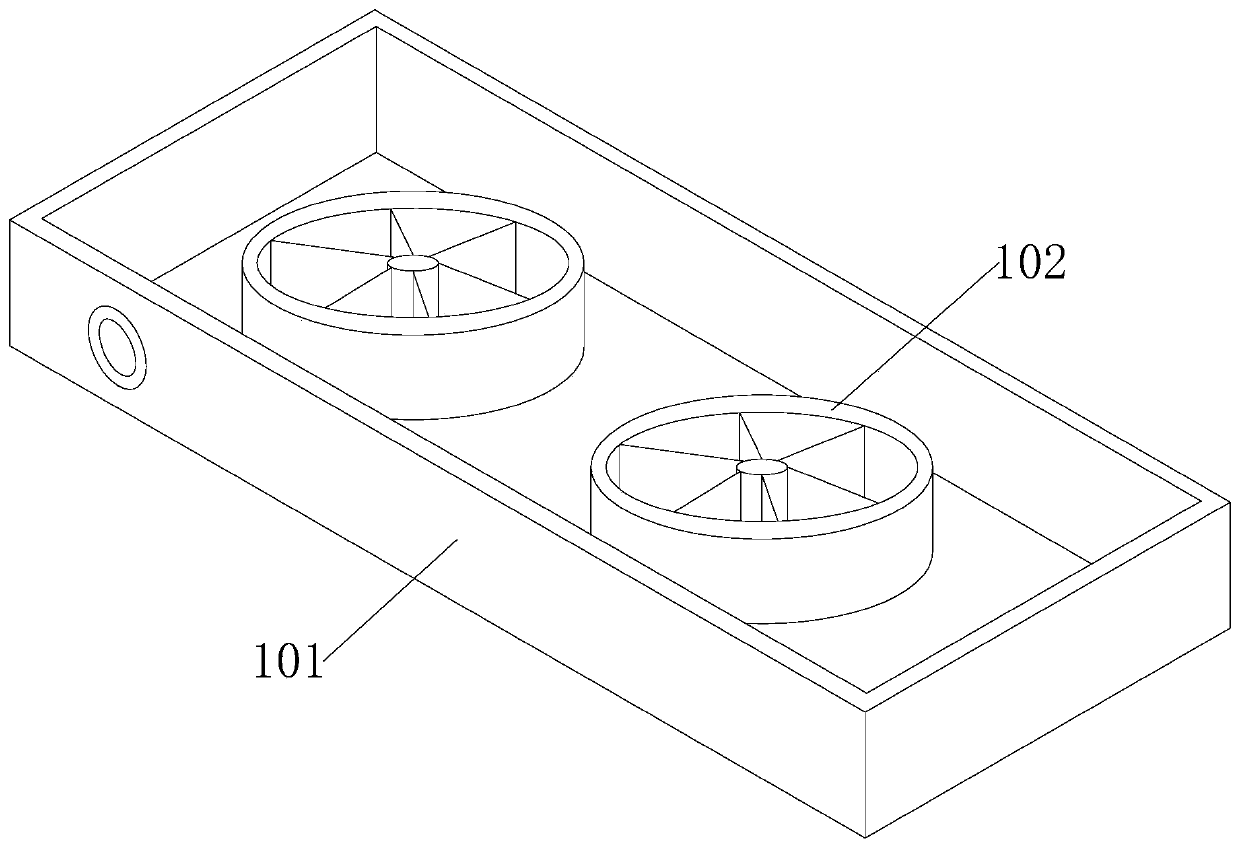

[0023] refer to Figure 1-5 , a bracket cleaning device for LED lighting production, comprising a cleaning box 1, a water flow drum 102, a lifting box 2 and a movable enclosure 205, the lower end surface of the cleaning box 1 is fixedly connected with a drive box 101, and the inner wall of the drive box 101 is provided with Two water flow drums 102, the upper end surface of the cleaning box 1 is fixedly connected with four lifting cylinders 207, the cleaning box 1 is movably connected with the lifting box 2 through the four lifting cylinders 207, and the lower end surface of the lifting box 2 is fixedly connected with a flexible connection frame 202, the upper end surface of the lifting box 2 is movably connected with a movable coaming 205, and the outer wall of the movable coaming 205 is provided with a clamp joint 206, and the side of the clamp joint 206 away from the movable coaming 205 is buckled and connected with a fixed block 2061. This kind of LED When the bracket clea...

Embodiment 2

[0025] refer to figure 1 and Figure 5 , a bracket cleaning device for the production of LED lamps, which is basically the same as that of Embodiment 1. Further, the right side wall of the cleaning box 1 is fixedly connected with a bracket storage box 103, and the bracket storage box 103 plays a role in storing and cleaning the brackets. The support storage box 103 is kept vertically arranged, and the inner wall of the support storage box 103 is provided with a hydrophobic layer, which avoids water stains remaining on the inner side wall of the support storage box 103, and the bottom surface of the support storage box 103 is provided with a plurality of through holes , it is convenient to drain the water and keep the inside of the bracket storage box 103 clean and dry.

[0026] The rear wall of the positioning frame 201 is provided with a rectangular through hole, and the interior of the rectangular through hole is connected with a pressing control block 2062. The pressing co...

Embodiment 3

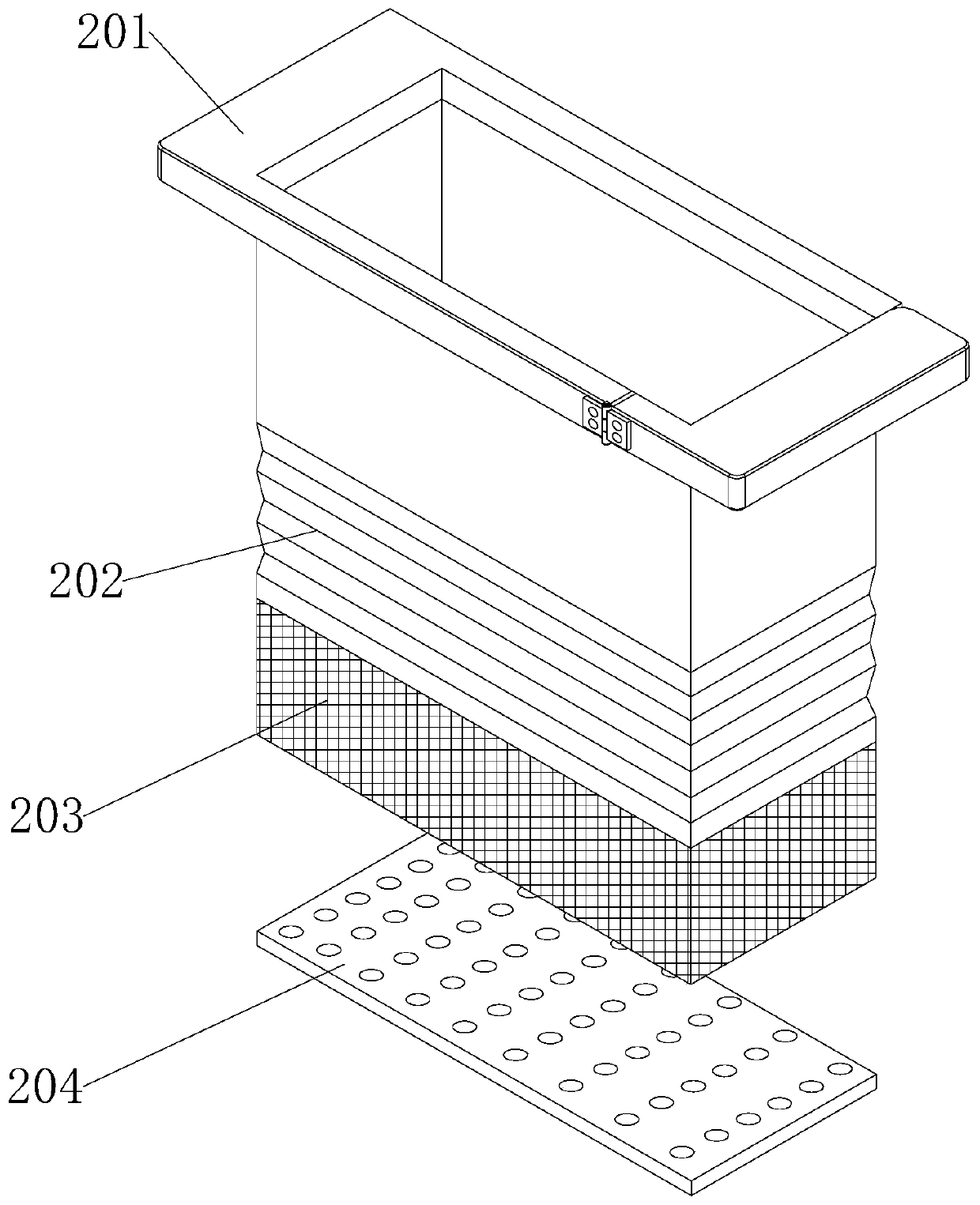

[0028] refer to image 3 , a bracket cleaning device for the production of LED lamps, which is basically the same as that of Embodiment 1, furthermore, the upper end surface of the lifting box 2 is fixedly connected with a positioning frame 201, and the right side of the positioning frame 201 is connected with a movable hoarding 205 through a loose-leaf , and the snap joint 206 is plugged into the inside of the positioning frame 201, the positioning frame 201 plays a role of positioning and fixing the lifting box 2, and the positioning frame 201 is hydraulically lifted by the cylinder 207, thereby realizing the lift of the entire lifting box 2 by the cylinder 207 control.

[0029] The lower end surface of the flexible connection frame 202 is fixedly connected with a permeable gauze 203, the cross-sectional size of the permeable gauze 203 is equal to the cross-sectional size of the flexible connection frame 202, and the axis of the permeable gauze 203 and the flexible connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com