Electrode and method for processing electrode

A processing method and electrode technology, which are applied in the field of foundry processing, can solve the problems of easy existence of burrs on the surface of a single electrode, the inability to ensure the processing accuracy of the deep and thin walls of a tubular core, and the easy deformation of a single electrode due to poor strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

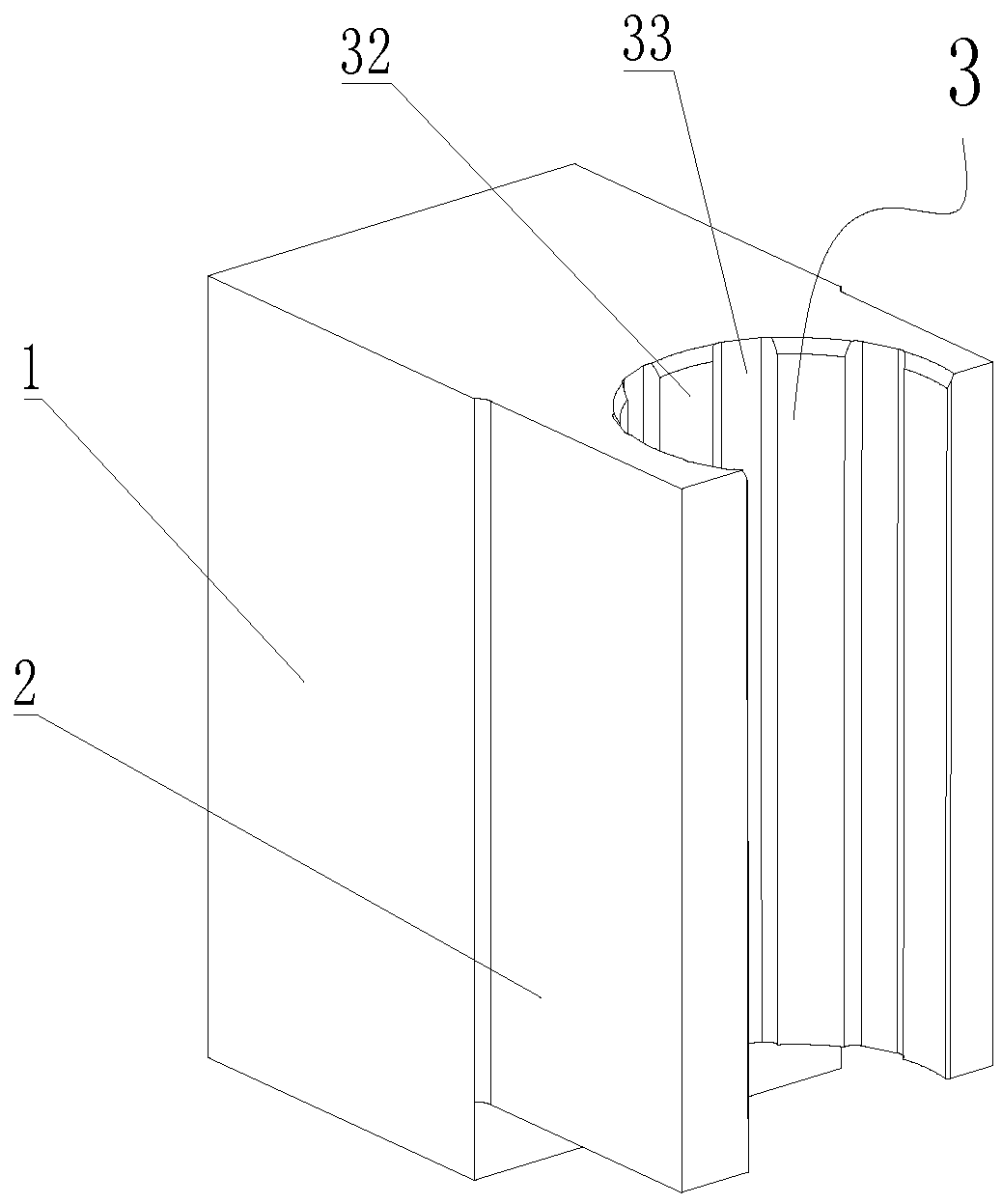

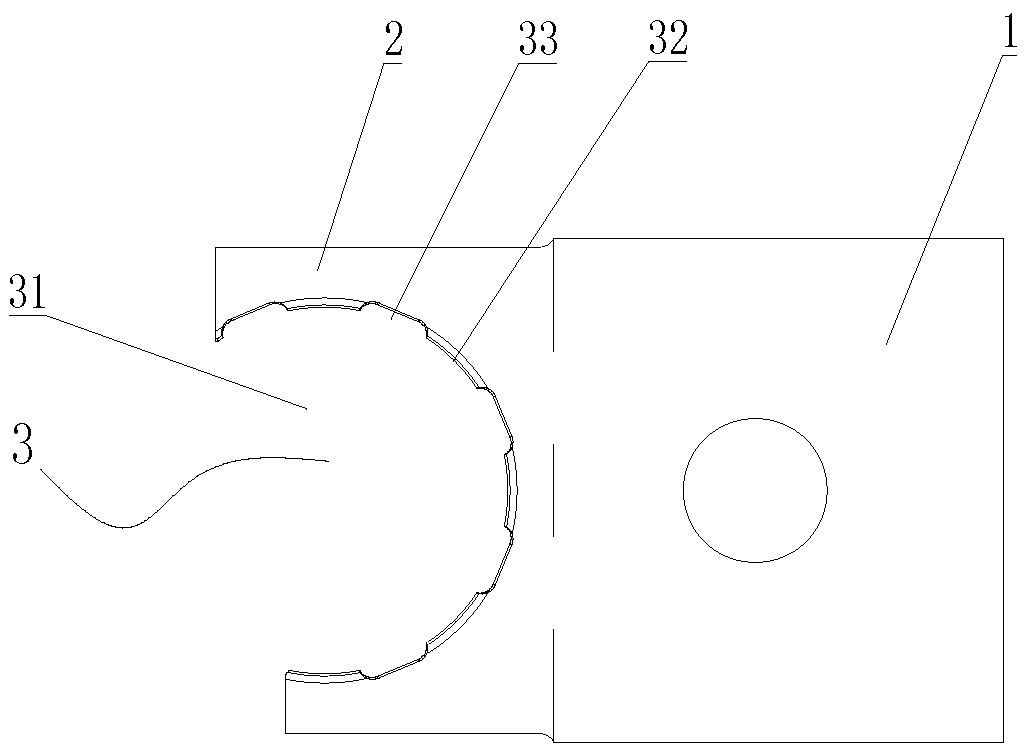

[0021] See Figure 1 to Figure 4 , a kind of electrode, its material is red copper, and integral electrode is assembled into one by 3 electrodes, and it comprises integrally formed electrode block one 1, electrode block two 2, and electrode block two 2 is provided with through groove 3, through groove 3 and The deep and thin-walled position 41 of the tubular core 4 matches, and one side of the through groove 3 is provided with an opening 31 corresponding to the deep and thin-walled position 41 of the tubular core;

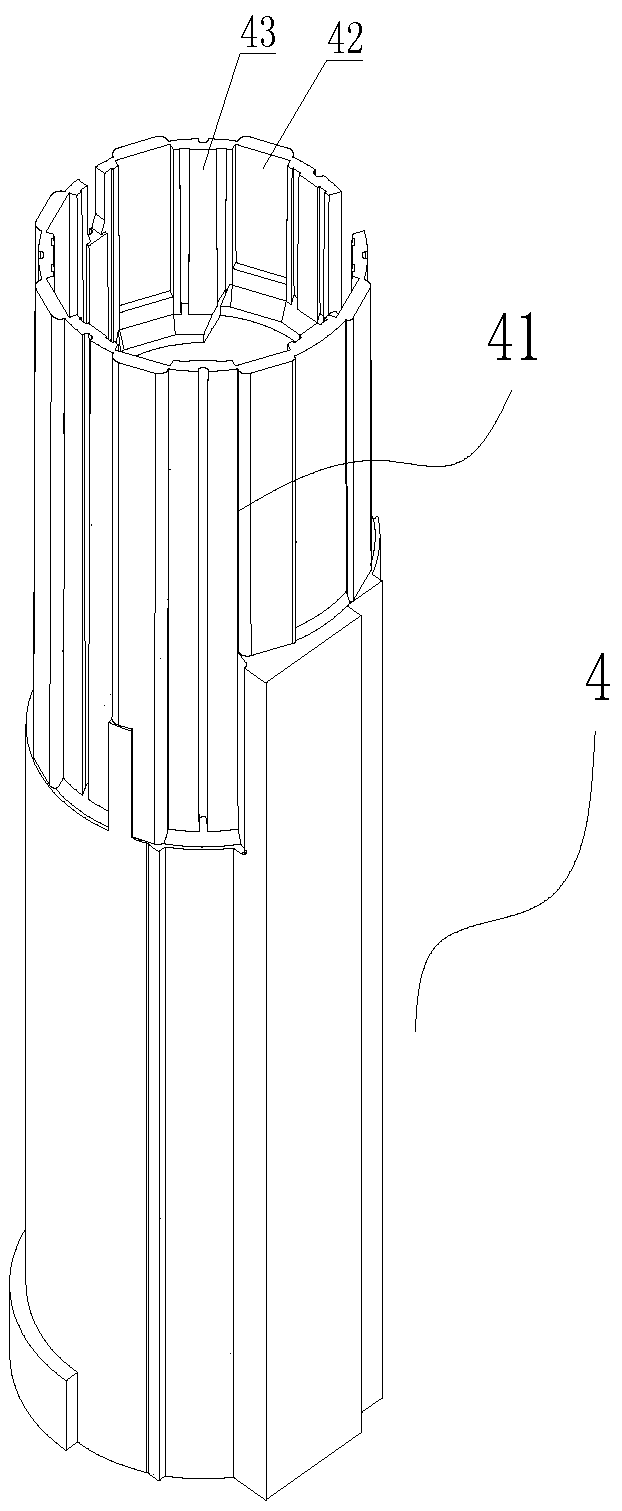

[0022] The deep and thin-walled position 41 is a groove one 42 and a protrusion one 43 arranged at a circumferentially evenly spaced structure; The second protrusion 32 and the second groove 33 are arranged correspondingly, and the recess depth of the second groove 33 is slightly larger than the protrusion height of the second protrusion 32 .

[0023] A processing method for processing the above-mentioned electrodes is characterized in that it comprises the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com