Large-curvature curved surface laser processing forming method

A technology of laser processing and forming method, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex laser processing trajectory, poor processing accuracy and low processing efficiency of large-curvature curved surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

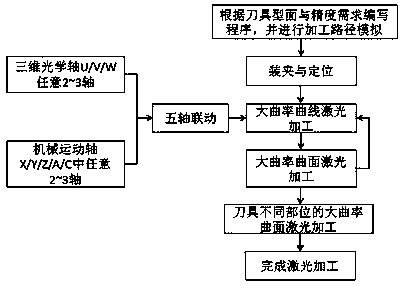

[0027] A laser processing and forming method for a curved surface with large curvature is characterized in that it comprises the following steps:

[0028] S1. According to the shape and size of the tool to be processed and the shape and precision requirements of the final tool, write the laser processing program and simulate the laser processing path;

[0029] S2. Clamp the tool to be processed to the central turntable on the laser machine tool, and use the probe to position the tool to be processed;

[0030] S3. Start the laser processing program, and perform one-time laser processing of the three-dimensional large curvature curve of the tool through the five-axis linkage between the optical axis of the laser galvanometer module and the mechanical movement axis of the machine tool;

[0031] S4. According to the laser processing path in the laser processing program in step S1, repeat step S3 to perform laser processing on the large curvature surface of the tool, with a surface...

Embodiment 2

[0042] A laser processing and forming method for a curved surface with large curvature is characterized in that it comprises the following steps:

[0043] S1. According to the shape and size of the tool to be processed and the shape and precision requirements of the final tool, write the laser processing program and simulate the laser processing path;

[0044] S2. Clamp the tool to be processed to the central turntable on the laser machine tool, and use the probe to position the tool to be processed;

[0045] S3. Start the laser processing program, and perform one-time laser processing of the three-dimensional large curvature curve of the tool through the five-axis linkage between the optical axis of the laser galvanometer module and the mechanical movement axis of the machine tool;

[0046] S4. According to the laser processing path in the laser processing program in step S1, repeat step S3 to carry out laser processing on the large curvature surface of the tool, with a surfa...

Embodiment 3

[0057] A laser processing and forming method for a curved surface with large curvature is characterized in that it comprises the following steps:

[0058] S1. According to the shape and size of the tool to be processed and the shape and precision requirements of the final tool, write the laser processing program and simulate the laser processing path;

[0059] S2. Clamp the tool to be processed to the central turntable on the laser machine tool, and use the probe to position the tool to be processed;

[0060] S3. Start the laser processing program, and perform one-time laser processing of the three-dimensional large curvature curve of the tool through the five-axis linkage between the optical axis of the laser galvanometer module and the mechanical movement axis of the machine tool;

[0061] S4. According to the laser processing path in the laser processing program in step S1, repeat step S3 to perform laser processing on the large curvature surface of the tool, with a surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com