Packing machine part tool for producing cartons

A technology for packaging machines and parts, applied in metal processing machinery parts, positioning devices, manufacturing tools, etc., can solve the problems of time-consuming, long time affecting production speed, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

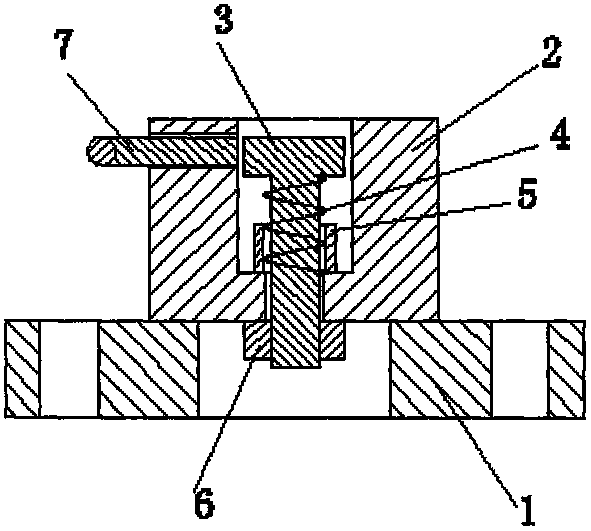

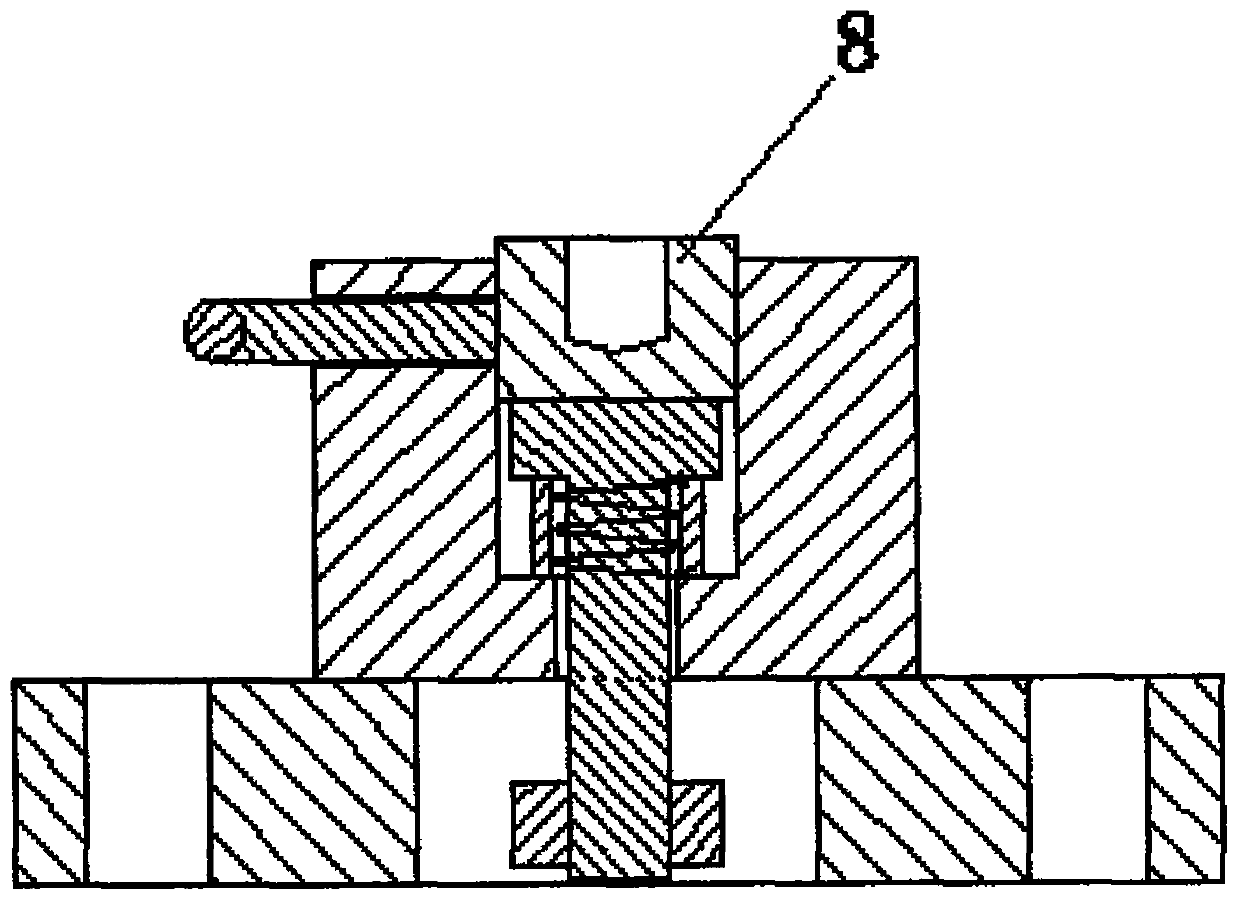

[0015] Now refer to figure 1 , 2 , 3, 4 and 5, are specifically described as follows in conjunction with embodiment:

[0016] A packaging machine parts tooling for producing cartons, comprising a base 1 and a main body block 2, a reference hole 11 is opened at the center of the main body block 2, and a supporting bolt is opened at the coaxial position of the lower end of the reference hole 11 Hole 12, reference ring 5 is set in reference hole 11, spring 4 is provided in reference ring 5, support bolt 3 passes through spring 4 and support bolt hole 12, is fixed by nut 6, and one side of main body block 2 has fastening bolt hole 13, and is provided with fastening bolts 7 for fixing the workpiece 8, and the lower end of the main body block 2 is provided with a base 1.

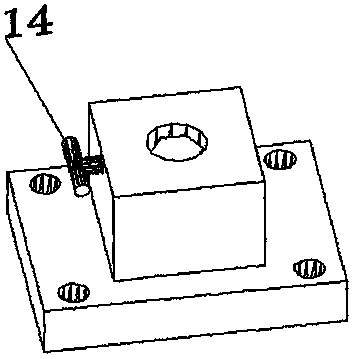

[0017] Preferably, a round steel 14 is welded to the outer end of the fastening bolt 7 .

[0018] Preferably, a base circular hole 9 is opened at the center of the base 1 , and base bolt holes 10 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com