Weather-resistant building material film and preparation method thereof

A building material film and weather-resistant technology, applied in chemical instruments and methods, building components, synthetic resin layered products, etc., can solve the problems of weak viscosity, long service life, and low transparency of building material films, and achieve non-degradable properties. , to prevent external cuts, improve the effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

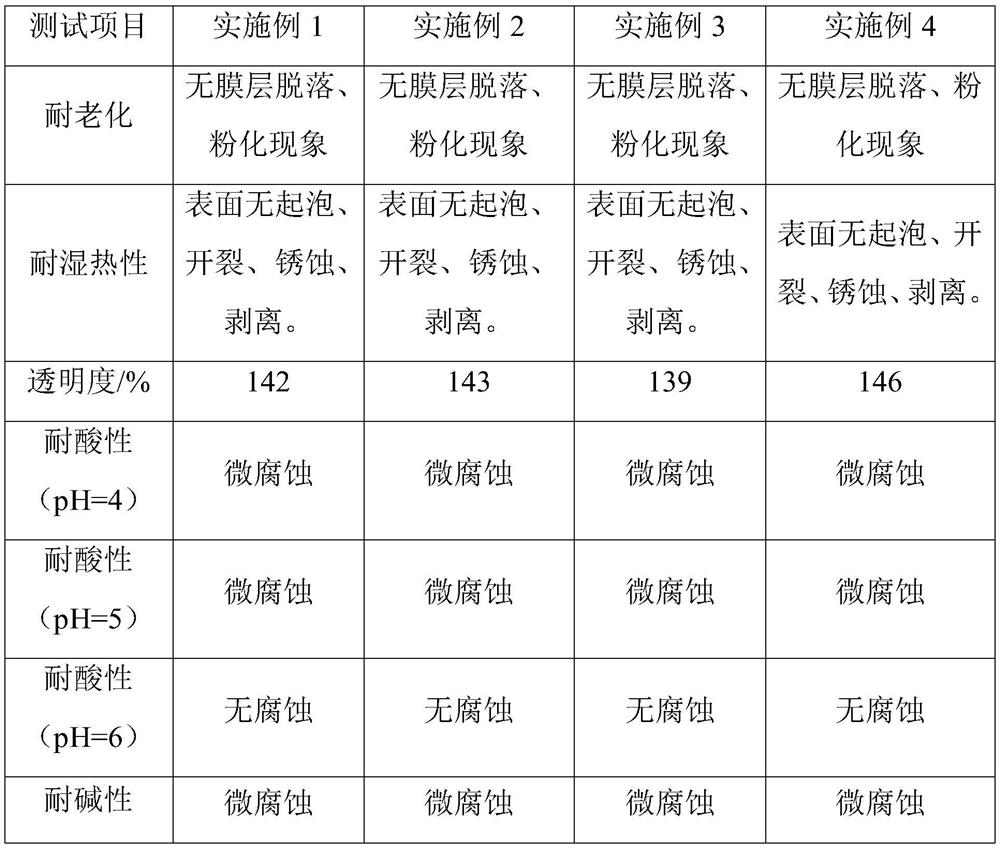

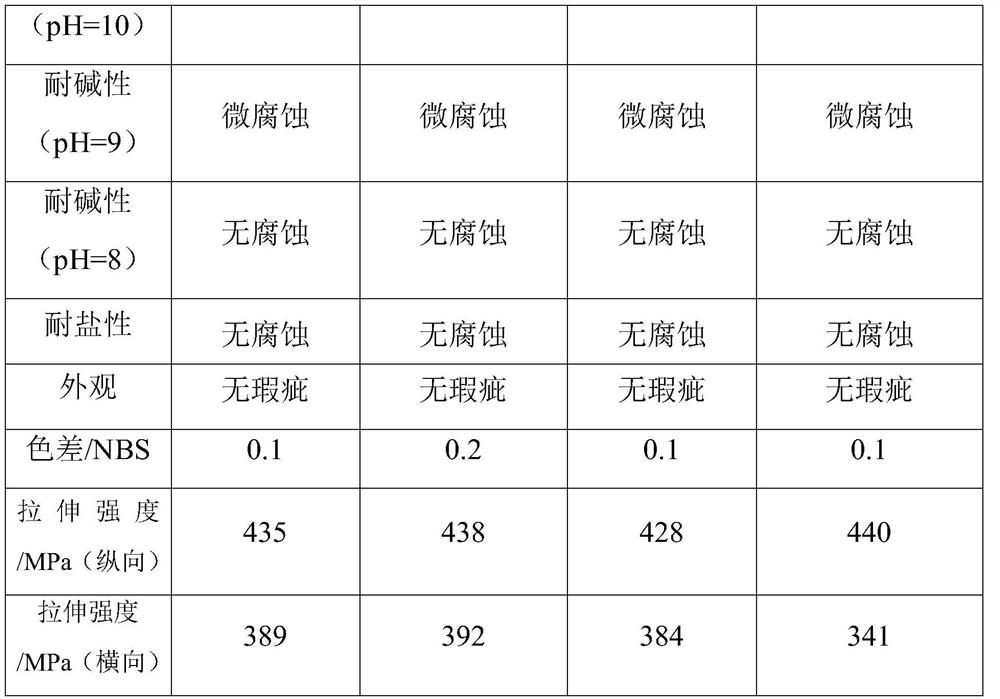

Examples

Embodiment 1

[0031] From the upper layer to the lower layer, the weather-resistant building material film is a fixedly connected outer layer film, an intermediate layer film and a veneer layer film.

[0032] The outer film includes the following components in parts by mass: 28 parts of glass fiber, 69 parts of PVC, 8 parts of titanium oxide, 6 parts of antioxidant, 10 parts of anti-reflection agent, and 6 parts of stabilizer. The antioxidant is molybdenum diisooctyl dithiophosphate, the anti-reflection agent is N, N vinylidene bis stearamide, and the thermal stabilizer is SW-977 methyl tin mercaptide.

[0033] The middle layer film includes the following components in parts by mass: 28 parts of glass fiber, 69 parts of PVC, 8 parts of titanium oxide, 8 parts of tackifier, 6 parts of antioxidant, 10 parts of anti-reflection agent and 2 parts of colorant . The antioxidant is molybdenum diisooctyl dithiophosphate, the anti-reflection agent is N, N vinylidene bis stearamide, the tackifier is ...

Embodiment 2

[0045] From the upper layer to the lower layer, the weather-resistant building material film is a fixedly connected outer layer film, an intermediate layer film and a veneer layer film.

[0046] The outer film includes the following components in parts by mass: 30 parts of glass fiber, 71 parts of PVC, 9 parts of titanium oxide, 7 parts of antioxidant, 11 parts of anti-reflection agent, and 7 parts of stabilizer. The antioxidant is copper dialkyl dithiocarbamate, the anti-reflection agent is N, N vinylidene bis stearamide, and the heat stabilizer is SW-977 methyl tin mercaptide. .

[0047] The middle layer film includes the following components in parts by mass: 30 parts of glass fiber, 71 parts of PVC, 9 parts of titanium oxide, 11 parts of tackifier, 7 parts of antioxidant, 11 parts of anti-reflection agent and 2 parts of colorant , the antioxidant is copper dialkyldithiocarbamate, the anti-reflection agent is N, N vinylidene bis stearamide, the tackifier is polyimide resin...

Embodiment 3

[0059] From the upper layer to the lower layer, the weather-resistant building material film is a fixedly connected outer layer film, an intermediate layer film and a veneer layer film.

[0060] The outer film includes the following components in parts by mass: 33 parts of glass fiber, 80 parts of PVC, 11 parts of titanium oxide, 7 parts of antioxidant, 14 parts of anti-permeability agent, 8 parts of stabilizer, and the antioxidant is Zinc dialkyl dithiocarbamate, the anti-permeation agent is N, N vinylidene bis stearamide, and the heat stabilizer is SW-977 methyl tin mercaptide.

[0061] The middle layer film includes the following components in parts by mass: 33 parts of glass fiber, 80 parts of PVC, 11 parts of titanium oxide, 14 parts of tackifier, 7 parts of antioxidant, 14 parts of anti-reflection agent and 4 parts of colorant , the antioxidant is zinc dialkyl dithiocarbamate, the anti-permeability agent is N, N vinylidene bis stearamide, the tackifier is citric acid, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com