Continuous vacuum production equipment for laminated glass

A technology of laminated glass and production equipment, applied in glass/slag layered products, layered products, layered product processing, etc., can solve the problems of low production efficiency, high energy consumption, single product type and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

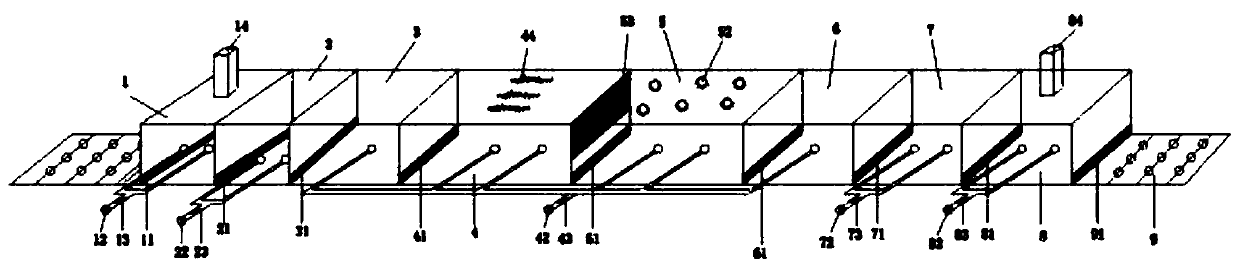

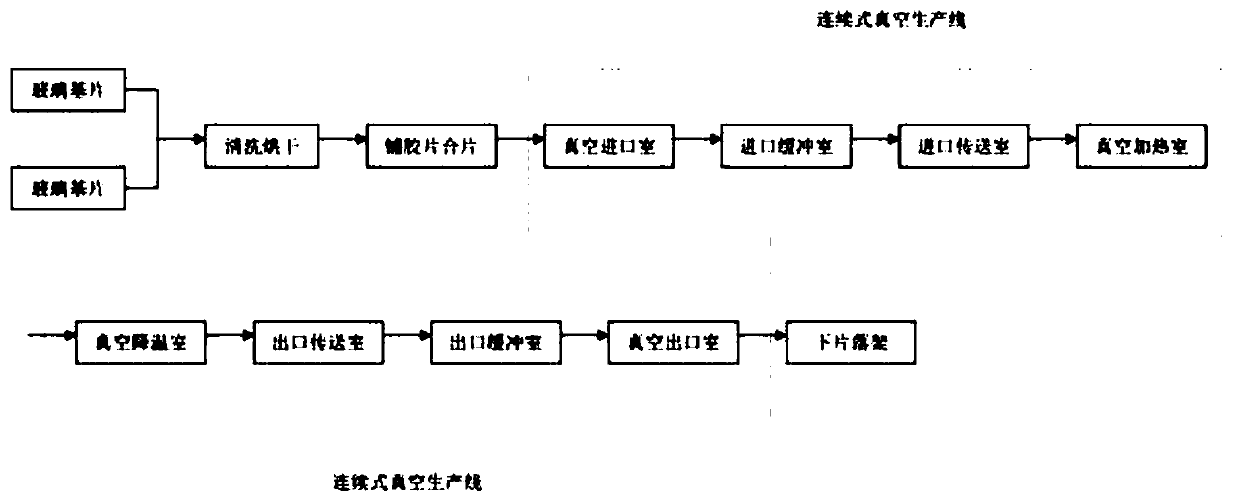

[0043] A kind of production method of the laminated glass of 6mm+1.52PVB+6mm, comprises the steps:

[0044] S1: Vacuum inlet chamber 1: Open the first door valve 11 under atmospheric conditions, the glass is conveyed into the vacuum inlet chamber 1, close the first door valve 11, open the first butterfly valve 13, the first vacuum pump group 12 enters the working state, and the vacuum degree reaches 10 -2 At hPa, the second gate valve 21 is opened, the glass is conveyed to the vacuum inlet buffer chamber, the second gate valve is closed, the first air release valve 14 is opened, and the pressure is restored to atmospheric pressure for a new round of glass conveyance; the conveying speed is 60 m / min.

[0045] S2: Vacuum inlet buffer chamber 2: The glass is transferred to the vacuum inlet buffer chamber, the second butterfly valve 23 is opened, the second vacuum pump group 22 enters the working state, and the vacuum degree reaches 10 -4 At hPa, the third gate valve 31 is opened,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com