Culture method for acid-tolerant alpha-amylase strains

A culture method and amylase technology, which are applied in biochemical equipment and methods, enzymology/microbiology devices, bioreactors/fermenters for specific purposes, etc., can solve the problem of slow heating area, uneven temperature, and temperature rise speed problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

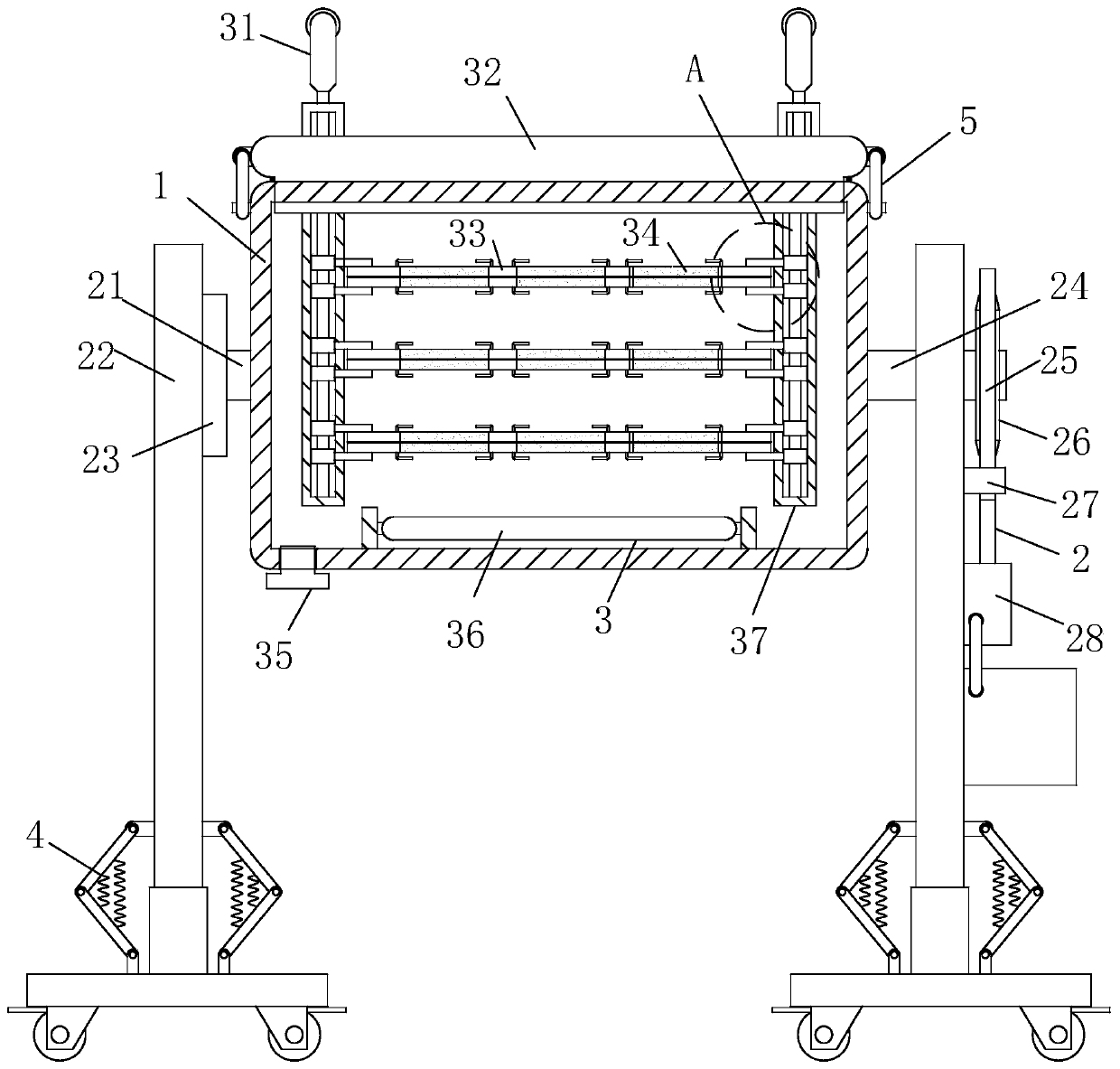

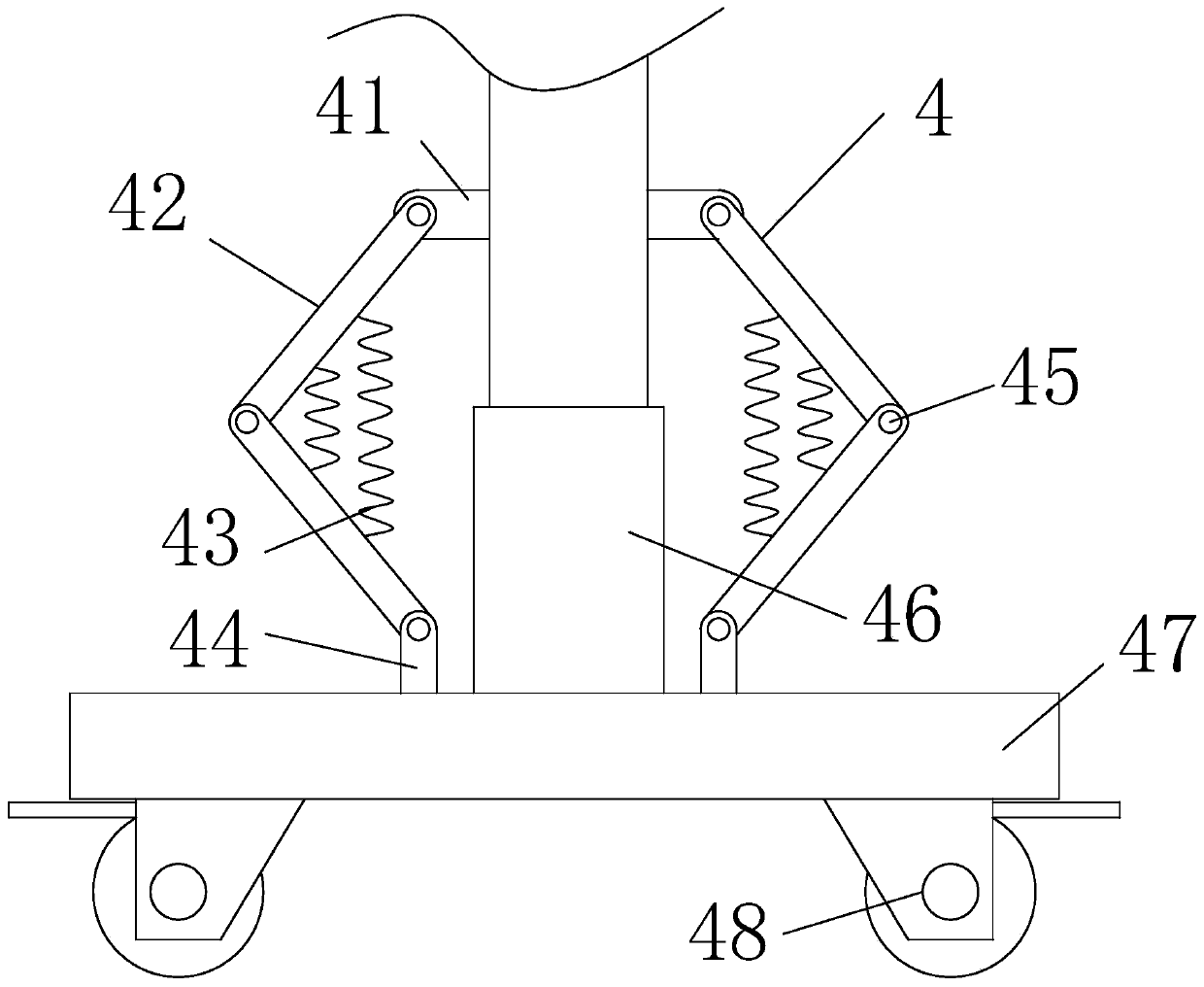

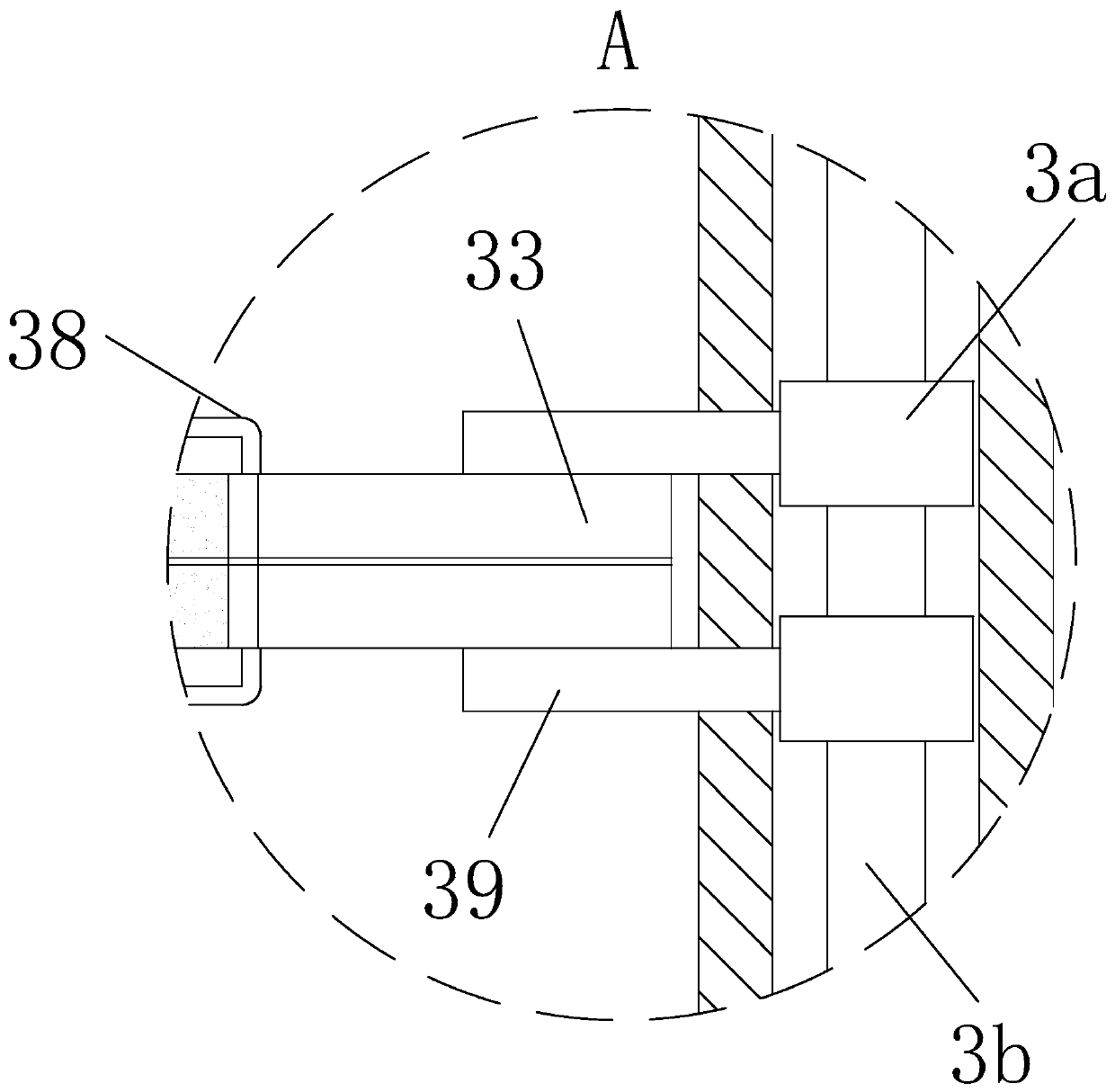

[0023] Please refer to figure 1 , figure 2 , image 3 and Figure 4 , a method for cultivating acid-resistant α-amylase strains, comprising the following steps:

[0024] s1, preparing medium for acid-resistant α-amylase strains;

[0025] s2, planting the acid-resistant α-amylase strain into the medium in s1 by streaking on a plate to form a petri dish;

[0026] s3, put the culture dish prepared in s2 into a special centrifugal homogeneous incubator for cultivation;

[0027] The special centrifugal uniform temperature incubator includes an incubator 1, a shaking structure 2, a petri dish storage heating structure 3 and a shock-absorbing support structure 4, the petri dish storage heating structure 3 is connected to the incubator 1, and the petri dish storage heating structure 3 Including drawing frame 31, cover plate 32, holding plate 33, sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com