Multi-station automatic bobbin case replacing, thread removing, winding and assembling integrated system and process method

A multi-station, bobbin case technology, which is applied in the direction of bobbin winding, auxiliary device, embroidery machine mechanism in sewing machines, etc., can solve the problems of cumbersome and laborious work of removing excess thread, easy bonding and winding of sewing thread, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

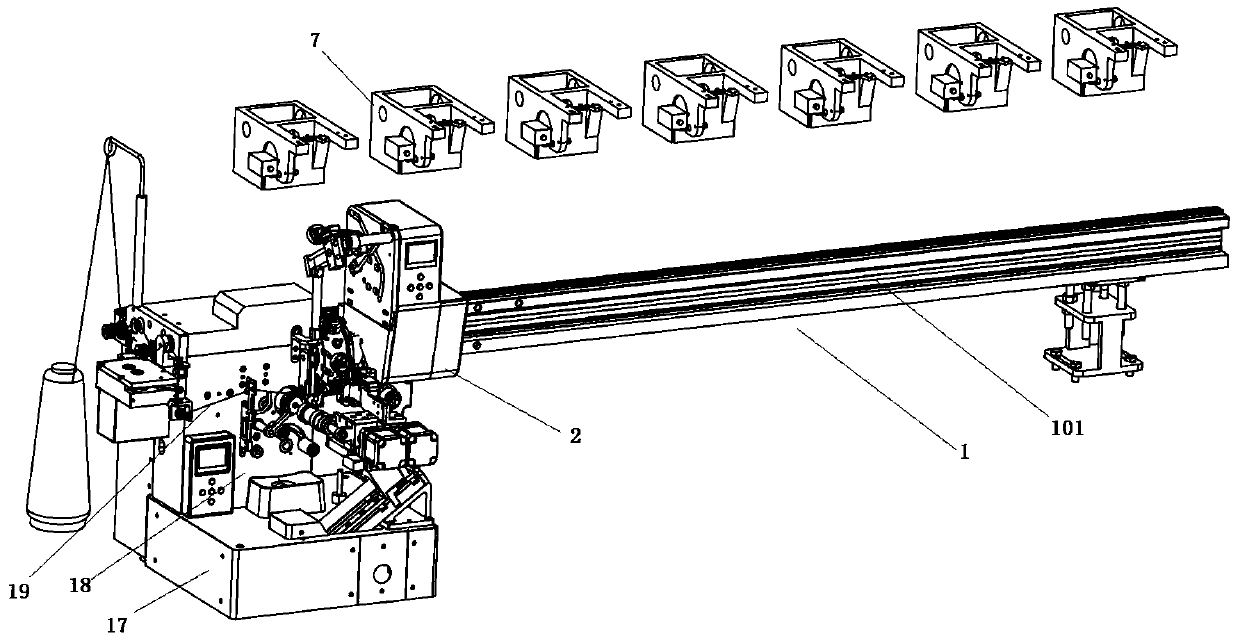

[0070] Such as figure 1 , figure 2 As shown in the present invention, a multi-station automatic bobbin case removal and winding assembly integrated system includes a horizontal guide rail, a bobbin case replacement device 2 and a bobbin removal and winding device.

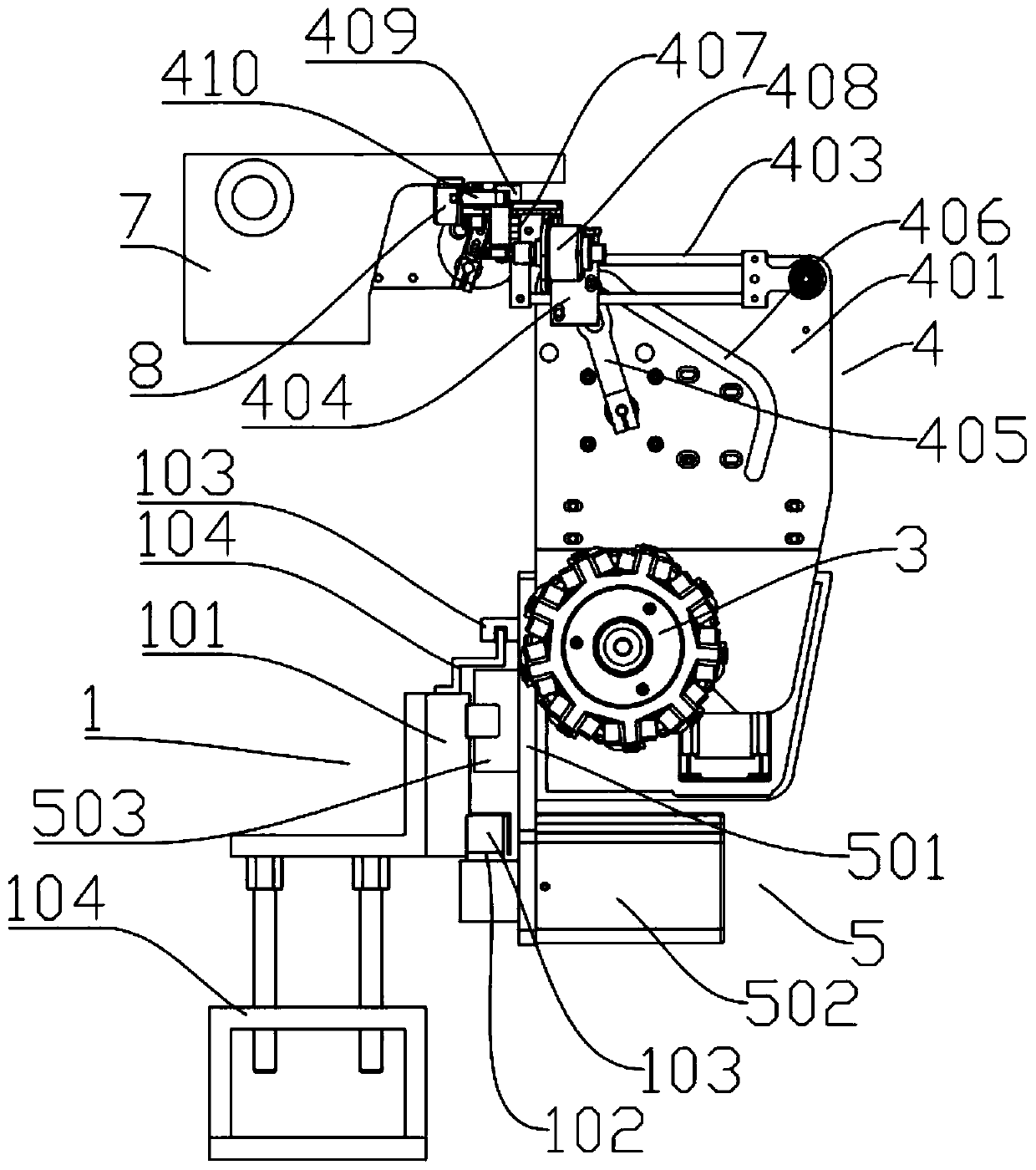

[0071] Such as image 3 , Figure 4 As shown, the horizontal guide mechanism 1 is arranged under the shuttle box body 7 of the embroidery machine, and the horizontal guide mechanism 1 extends along the connecting line direction of each shuttle box body 7. The bobbin case replacement device 2 includes a bobbin case grasping part 4, The bobbin case storage part and the translation drive part 5, the translation drive part 5 is slidably connected to the horizontal guide mechanism 1 and can translate and slide along the horizontal guide mechanism 1. The bobbin case storage part inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com