Combined beam for shock-proof safety bin and manufacturing method thereof

A manufacturing method and technology for beams, which are applied in earthquake resistance, building structure, building components, etc., can solve the problems of high beam quality, low hardness, and difficulty in installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

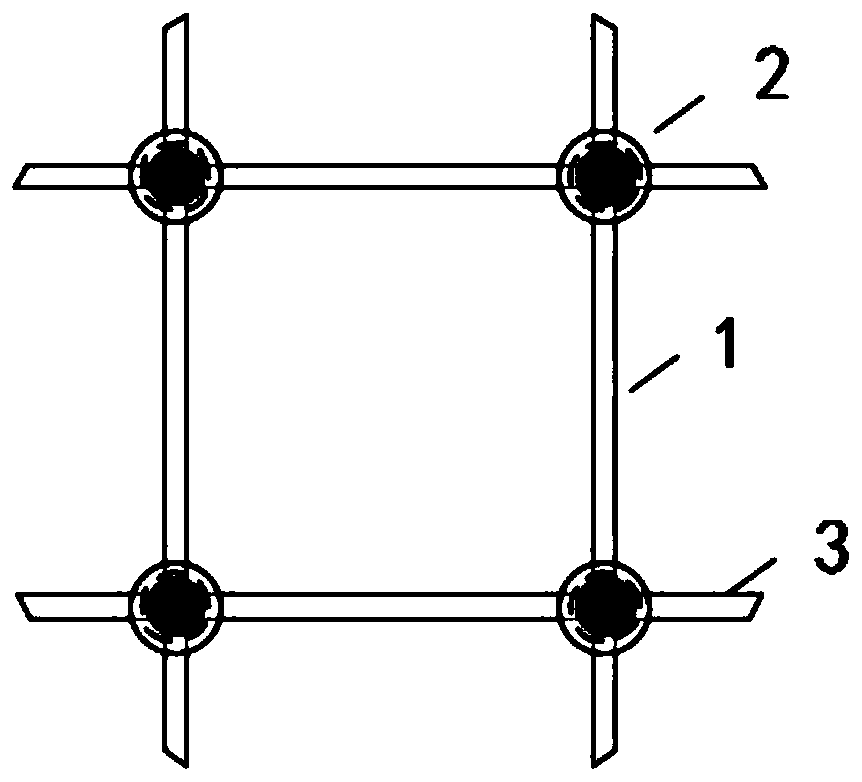

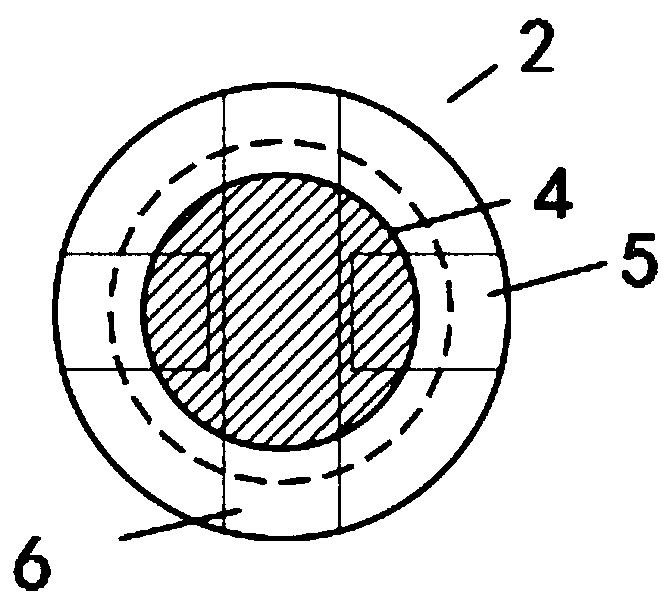

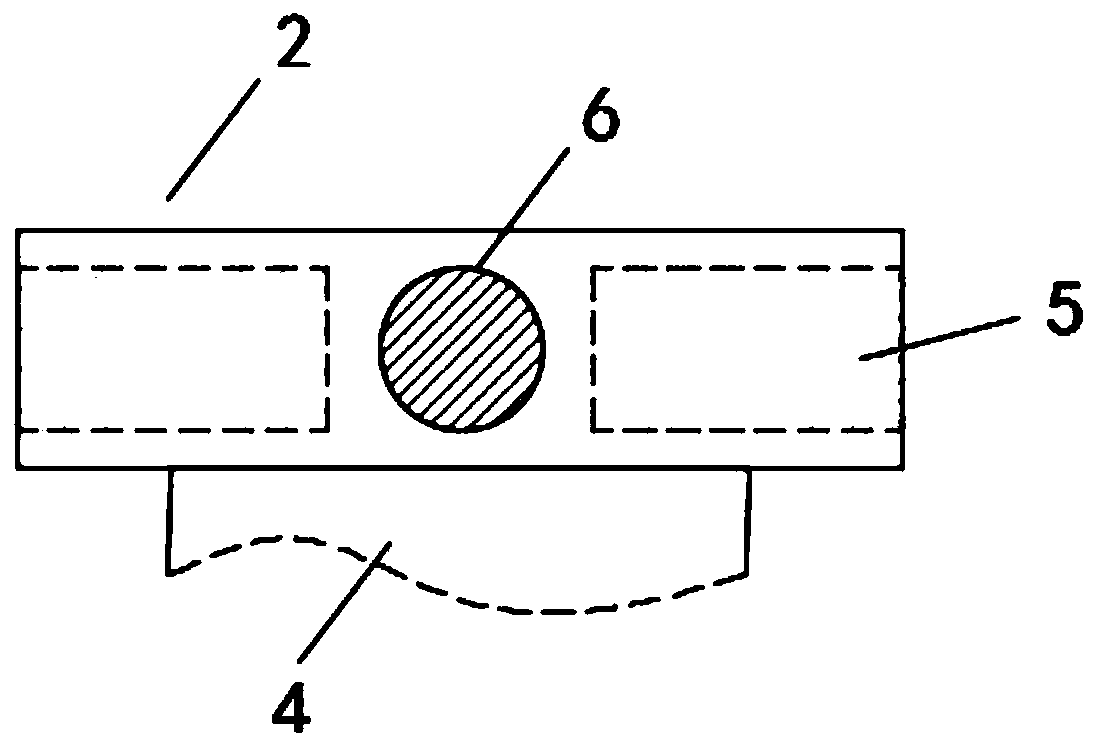

[0025] Such as Figure 1-Figure 3 As shown, this specific embodiment adopts the following technical solutions: a composite beam for a shock-absorbing safety storehouse, including a composite beam 1, a beam combination mechanism 2, a beam column 3, a load-bearing column 4, a short slot 5 and a long slot 6, The combined beam 1 is composed of a beam combination mechanism 2 and a beam column 3. The bottom of each beam combination mechanism 2 is fixedly connected with a load-bearing column 4, and each beam combination mechanism 2 is composed of a short slot 5 and a Slotted hole 6 constitutes.

[0026] Wherein, two short slots 5 and one long slot 6 are provided on each beam combination mechanism 2, and the two short slots 5 are located on the same straight line, and the straight line where the short slots 5 are located Perpendicular to each other with long slotted hole 6, convenient to use.

[0027] Wherein, the inner diameters of the short slot 5 and the long slot 6 are the same,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com