Acid-method in-situ leaching mine stratum plug-removing method

An in-situ leaching and mining technology, applied in chemical instruments and methods, earthwork drilling, cleaning equipment, etc., can solve problems such as chemical blockage of boreholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

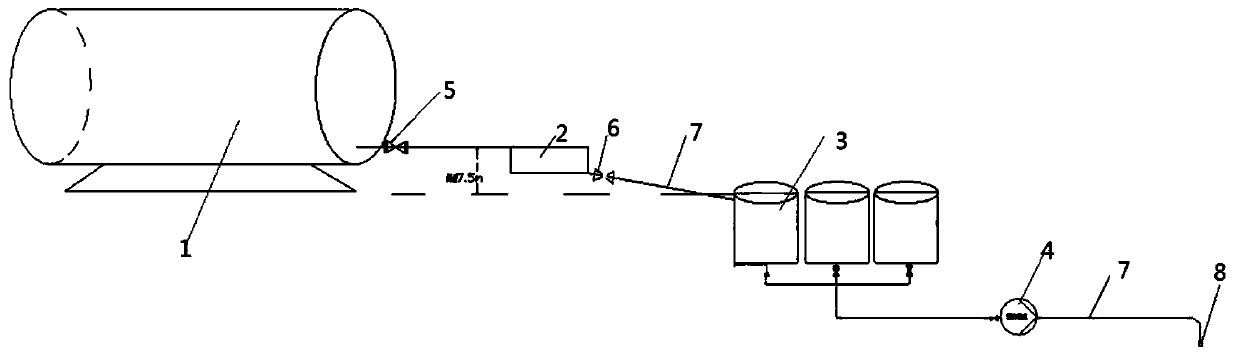

[0027] The present invention will be further described in detail below by taking the 512 ore deposit I and II cycle ore body mining area as an example, in conjunction with the accompanying drawings and specific embodiments.

[0028] This embodiment provides a method for unblocking the formation of mines by acid in-situ leaching, to remove the chemical blockage near the filter, near the wellbore and deep in the formation, to restore the leaching channel near the ore layer and the filter, to restore the permeability of the formation, and to achieve Economic exploitation of uranium resources. The method comprises the steps in turn:

[0029] S1. Build plugging remover configuration device

[0030] S1.1 Prepare the components required for the plugging agent configuration device, the composition of the plugging agent configuration device is as follows figure 1 As shown, its main components include: 1 hydrochloric acid storage tank 1 with a volume of 70m 3 ; 63×10mmPE liquid injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com