Method of processing cement sheath outside screen pipe after cementing well completion

A treatment method and cement sheath technology, which are used in earth-moving drilling, flushing wellbore, wellbore/well components, etc., can solve the problems of affecting the strength of the screen, increase the cost of completion, and reduce the inner diameter, and achieve economical efficiency. The effect of de-perforation process, production cost reduction, and permeability recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings, without limiting the protection scope of the present invention.

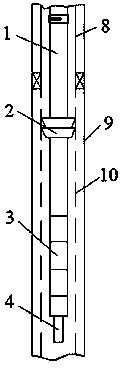

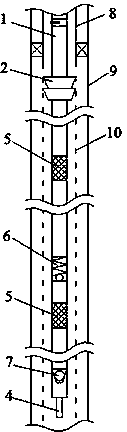

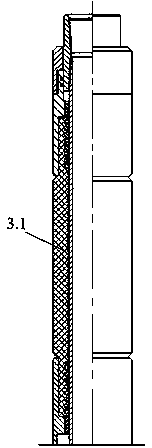

[0023] see figure 1 and figure 2 , the treatment method of the cement sheath outside the screen pipe after cementing completion, use the cement sheath outside the screen pipe to squeeze the pickling string down to the design position of the screen pipe 10, close the casing valve and blowout preventer at the wellhead, and use the screen pipe Cement sheath extrusion outside the pipe The cement sheath extrusion device 3 in the pickling string seals the annulus between the oil pipe 1 and the screen pipe 10, and presses and squeezes the screen pipe outside the cement sheath extrusion device 3 from the oil pipe 1 The outer cement sheath is drilled down to the bottom of the artificial well section by section; use the outer cement sheath of the screen to squeeze the pickling string to open the well flushing va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com