Steam turbine generator unit rotor eccentricity and phase measuring device and method

A steam turbine generator set and rotor eccentricity technology, which is applied to measuring devices, electrical devices, optical devices, etc., can solve the problems of inaccurate measurement, the influence of rotor jacking height fluctuations, and the inability to properly reflect the bending degree of the rotor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

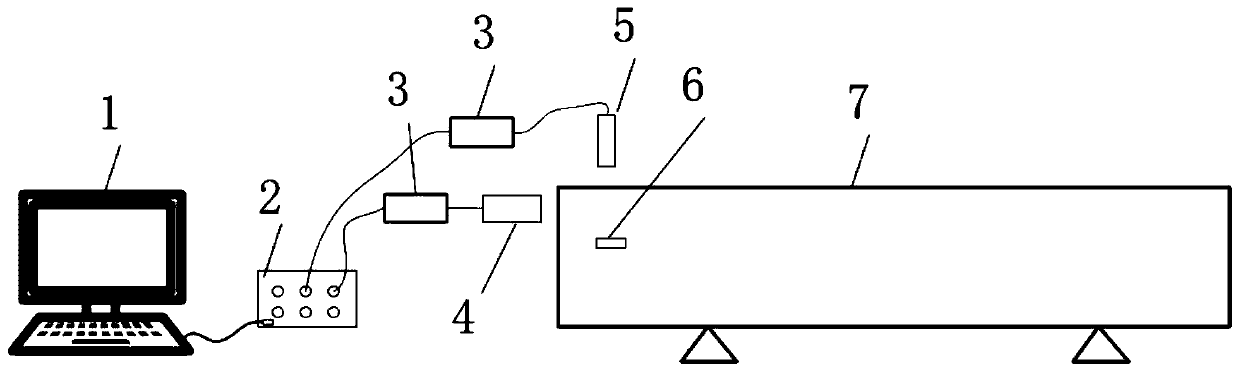

Embodiment 1

[0050] Embodiment 1: as figure 1 Shown, a turbogenerator rotor eccentricity and its phase measurement device, including a key phase sensor 5 and a shaft displacement sensor 4, the key phase sensor 5 and the shaft displacement sensor 4 are respectively connected with two front-end devices 3, two front-end devices The output terminal of 3 is connected with the data acquisition equipment 2, and the data acquisition equipment 2 is connected with the computer 1, and the key phase sensor 5 is installed beside the measuring groove 6 on the circumferential surface of the rotor 7 or the extension shaft of the rotor 5, and the probe of the key phase sensor 5 is For the measurement slot 6, the shaft displacement sensor 4 is facing the rotor end face of the turbogenerator set and is perpendicular to the rotor end face. The resolution of the data acquisition equipment is greater than or equal to 16 bits, and the number of channels is greater than or equal to 2. Both the key phase sensor an...

Embodiment 2

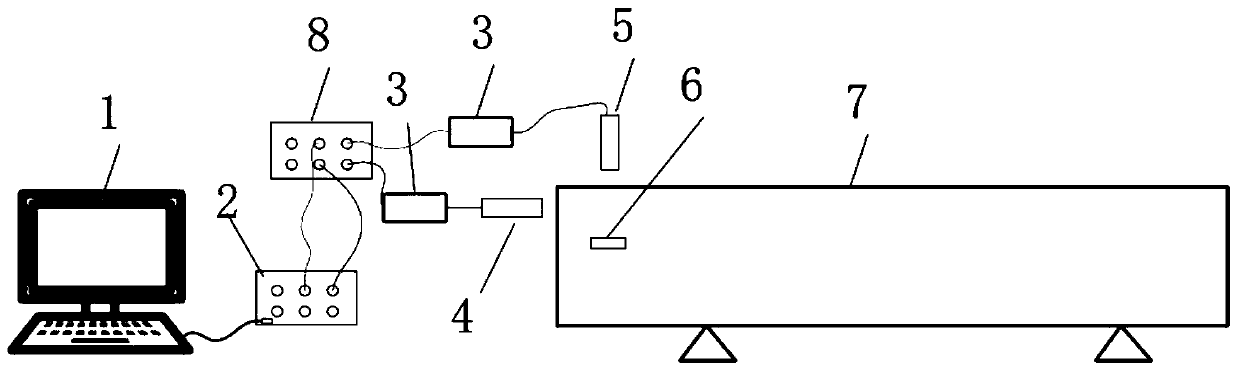

[0053] Embodiment 2: as figure 2 Shown, a turbogenerator rotor eccentricity and its phase measurement device, including a key phase sensor 5 and a shaft displacement sensor 4, the key phase sensor 5 and the shaft displacement sensor 4 are respectively connected with two front-end devices 3, two front-end devices The output terminal of 3 is connected to the data acquisition device 2 through the TSI system 8, the data acquisition device 2 is connected to the computer 1, the key phase sensor 5 is installed beside the measuring groove 6 on the circumferential surface of the rotor 7 or the extension shaft of the rotor 5, and the key phase sensor The probe of 5 is facing the measurement groove 6, the shaft displacement sensor 4 is facing the rotor end face of the turbogenerator set, and is perpendicular to the rotor end face, the resolution of the data acquisition equipment is greater than or equal to 16 bits, and the number of channels is greater than or equal to 2.

[0054] Prefe...

Embodiment 3

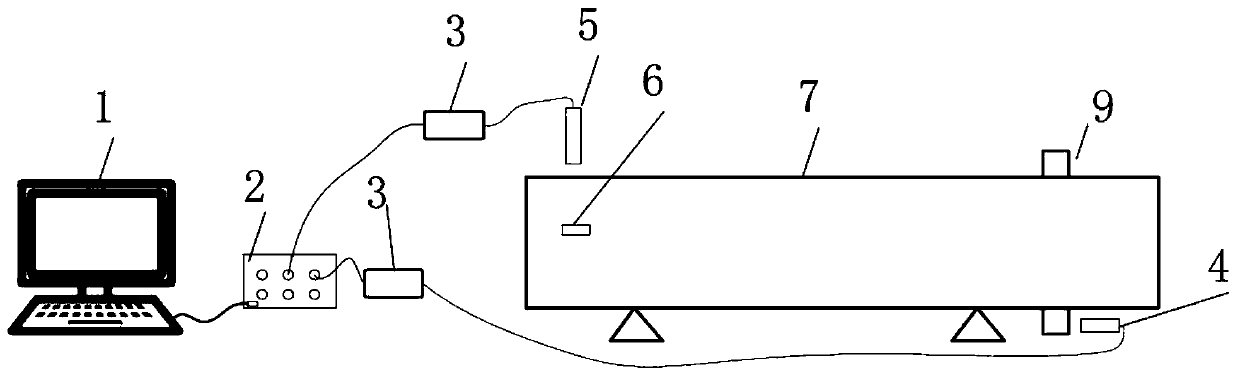

[0056] Embodiment 3: as image 3 Shown, a turbogenerator set rotor eccentricity and its phase measurement device, including a key phase sensor 5 and a shaft displacement sensor 4, the shaft displacement sensor 4 is replaced by a differential expansion sensor, the differential expansion sensor and the shaft displacement sensor 4 are respectively connected to the two front The output terminals of the two pre-processors 3 are connected with the data acquisition device 2, the data acquisition device 2 is connected with the computer 1, and the key phase sensor 5 is installed beside the measuring groove 6 on the surface of the rotor 7 or the extension shaft of the rotor 5 , and the probe of the key phase sensor 5 is facing the measurement groove 6, the differential expansion sensor is facing the rotor end face of the turbogenerator set, and is perpendicular to the rotor end face, the resolution of the data acquisition equipment is greater than or equal to 16bit, and the number of cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com