Soil improvement method for garden planting

A soil improvement and gardening technology, applied in the fields of land preparation methods, applications, agricultural machinery and implements, etc., can solve the problems of large external force, large physical effort, and high work intensity of construction personnel, so as to achieve the goal of not easy to harden again, save physical strength, and help effect on soil improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

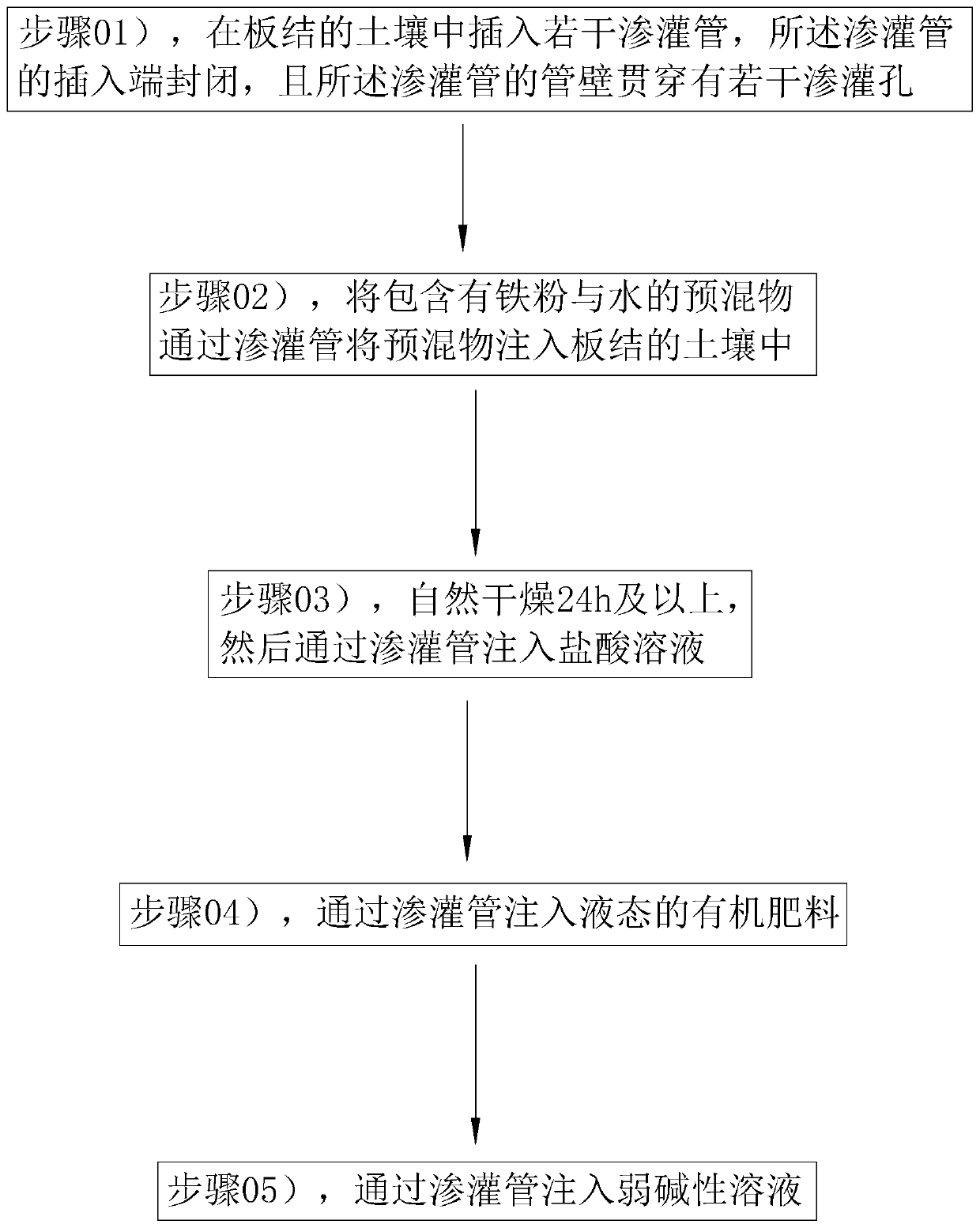

[0050] refer to figure 1 , is a garden planting soil improvement method disclosed by the present invention, comprising the following steps:

[0051] Step 01), on-site investigation, delineate the range where the garden planting soil is compacted, insert the infiltration irrigation pipe vertically in the compacted soil, the length of the infiltration irrigation pipe is 1m, and the insertion end of the infiltration irrigation pipe is closed and conical. The inner diameter of the irrigation pipe is 20mm, and the wall thickness of the irrigation pipe is 4mm. There are densely distributed irrigation holes running through the wall of the irrigation pipe. The diameter of the irrigation holes is 0.2mm. The vertical distance is 1.8mm, and the vertical distance between the axes of adjacent irrigation pipes is 5m.

[0052]Step 02), add water and iron powder in the mixing tank, the water is tap water that has been left to stand for more than 48 hours, the iron powder is ground to a parti...

Embodiment 2

[0057] Compared with Example 1, the difference is only in:

[0058] In step 01), the diameter of the irrigation holes is 0.1 mm, and the vertical distance between the axes of adjacent irrigation holes is 1.5 mm.

[0059] In step 02), the iron powder is ground to a particle size of 10nm by grinding equipment, and the mass ratio of water to iron powder is 100:33; when injecting the premix, keep at a constant pressure of 1 MPa for 1 min.

[0060] In step 03), after all the permeation and irrigation pipes are injected with the premix, they are naturally dried for 36 hours under sunny conditions; the concentration of the hydrochloric acid solution is 15%.

[0061] In step 05), the weak alkaline solution adopts a sodium bicarbonate solution with a concentration of 3%.

Embodiment 3

[0063] Compared with Example 1, the difference is only in:

[0064] In step 01), the diameter of the irrigation holes is 0.5mm, and the vertical distance between the axes of adjacent irrigation holes is 2mm.

[0065] In step 02), the iron powder is ground to a particle size of 100nm by grinding equipment, and the mass ratio of water to iron powder is 100:44; when injecting the premix, maintain a constant pressure of 2MPa for 1min.

[0066] In step 03), after all the permeation and irrigation pipes are injected with the premix, they are naturally dried for 48 hours under sunny conditions; the concentration of the hydrochloric acid solution is 20%, and when the hydrochloric acid solution is injected, keep it at a constant pressure of 2 MPa for 3 minutes.

[0067] In step 05), the weak alkaline solution adopts a sodium bicarbonate solution with a concentration of 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com