Environment-friendly foam breaker production filtering equipment

A technology of filtering equipment and foam breaking agent, which is applied in the direction of filtration separation, filtration circuit, foam dispersion/prevention, etc., which can solve the problems of inability to filter the foam breaking agent, the impact of the production of the foam breaking agent, and the accumulation of the foam breaking agent. Effects of filtration treatment, improvement of filtration efficiency, and slowing down of flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

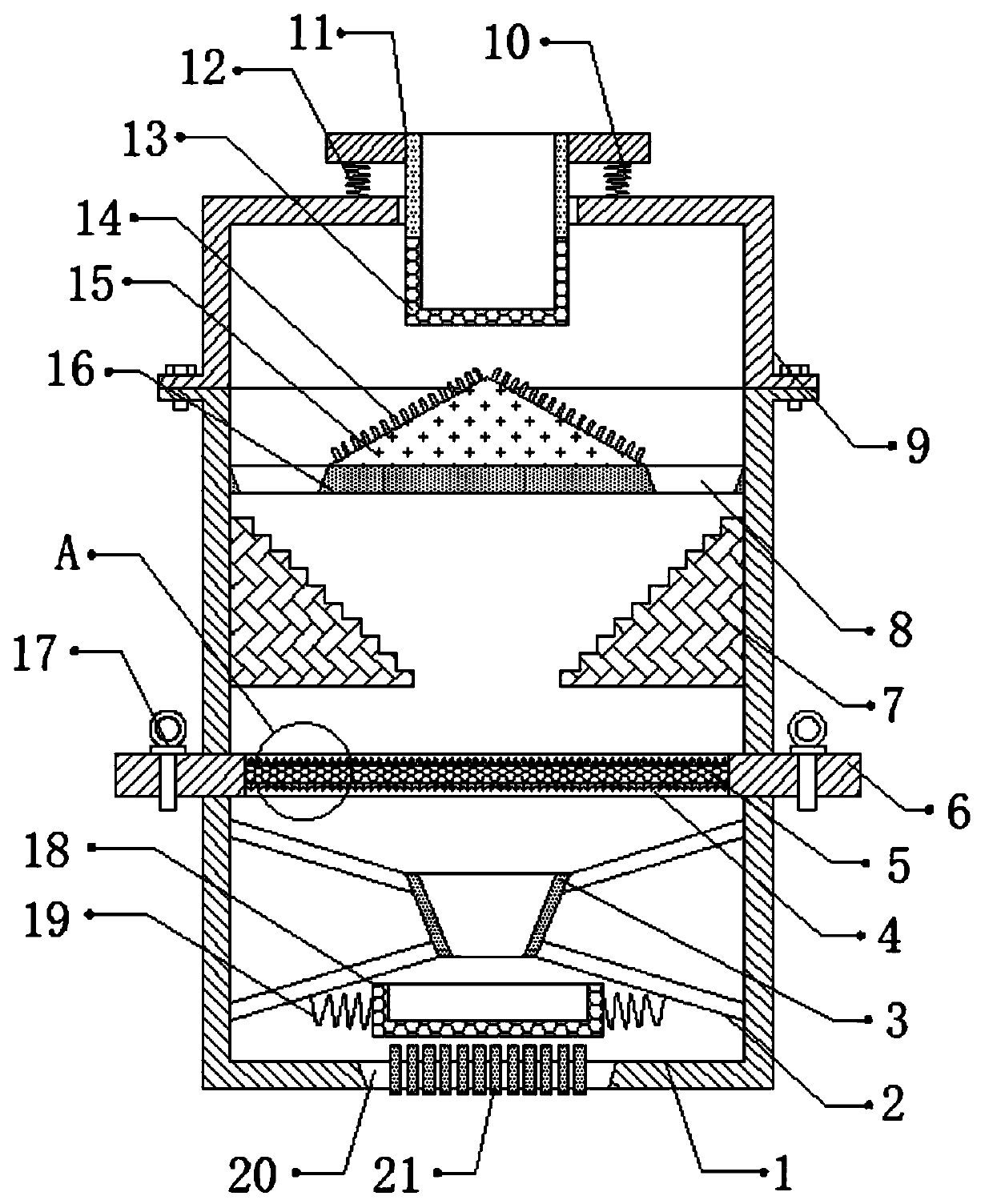

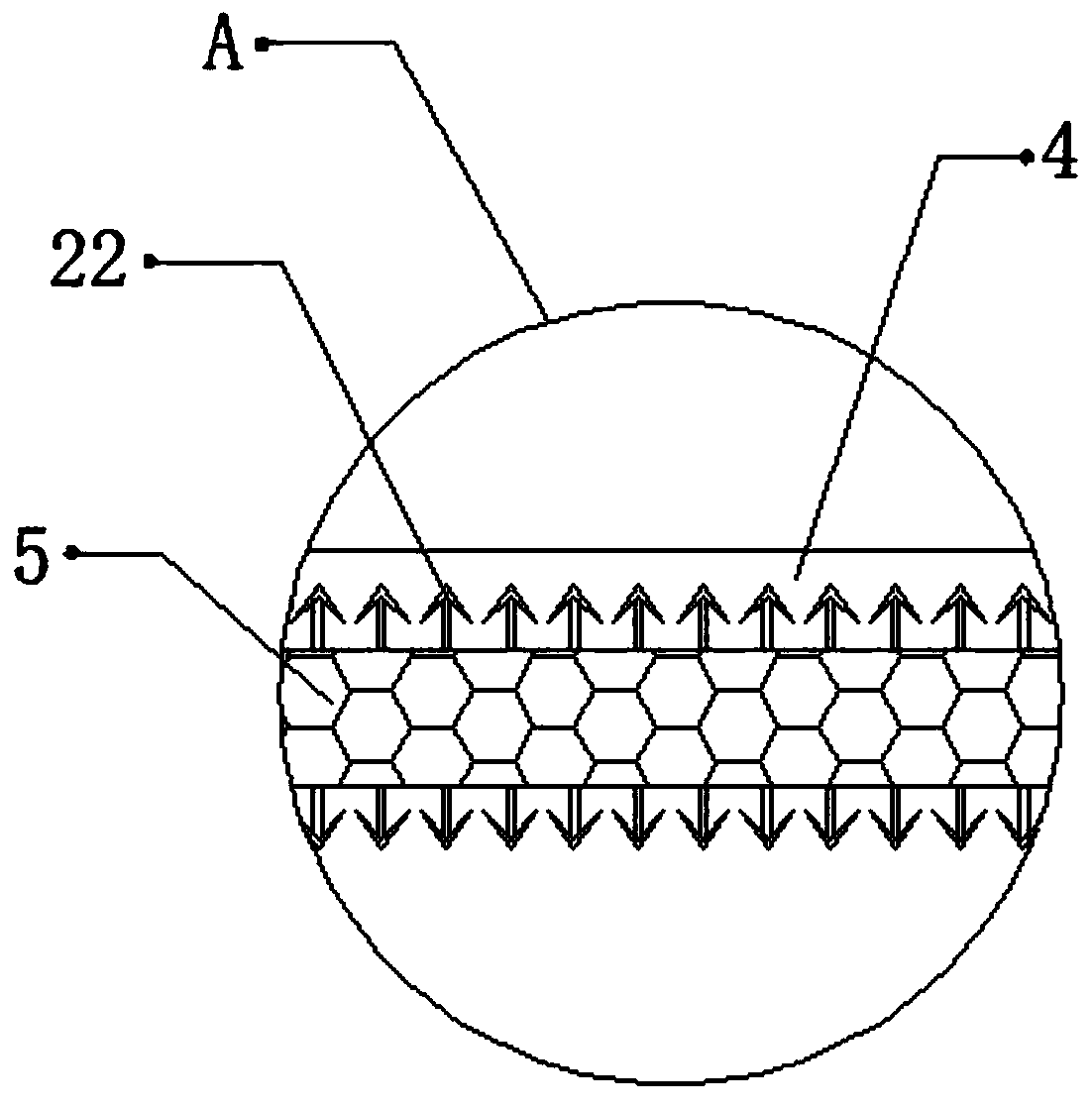

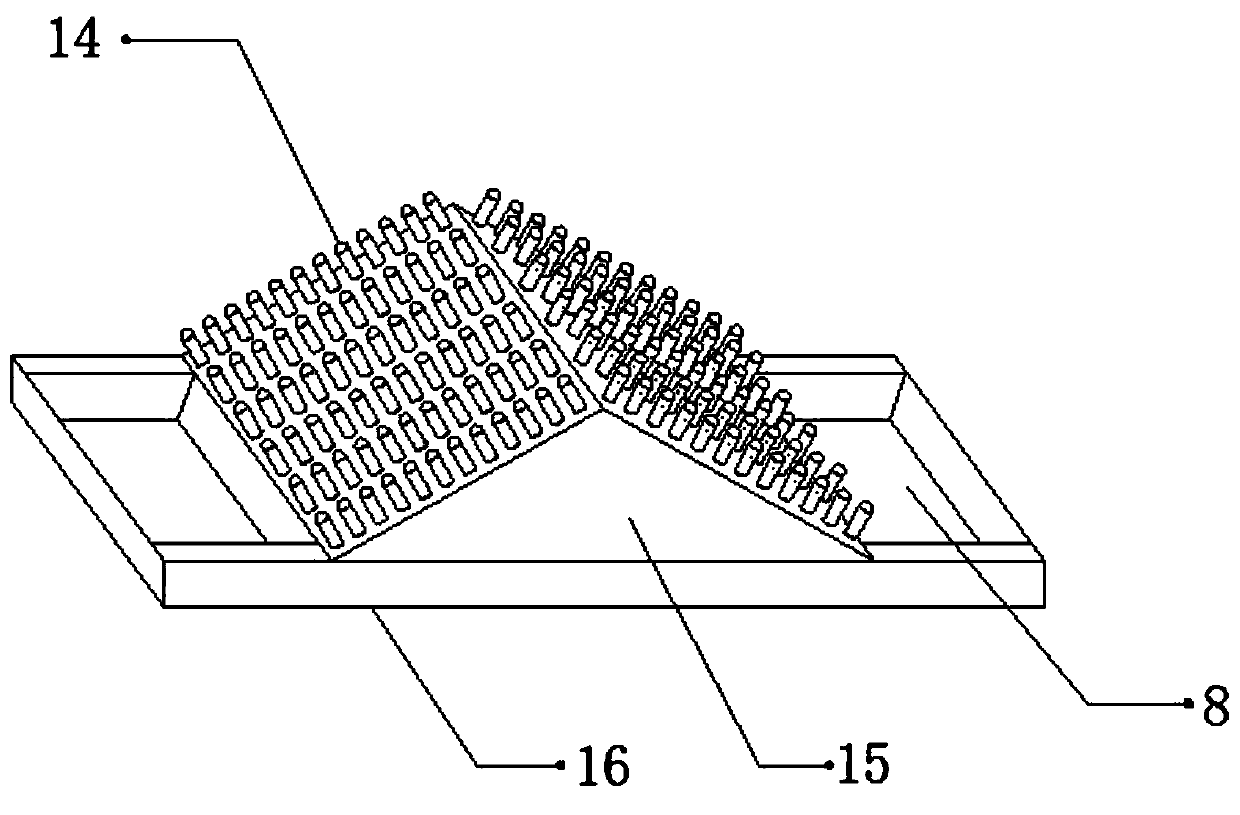

[0030] refer to Figure 1-3 , a filter device for the production of an environmentally friendly foam breaker, comprising a filter box 1, the top outer wall of the filter box 1 is connected with a box cover 9 by bolts, and the top outer wall of the box cover 9 is provided with a feed port, and the top outer wall of the box cover 9 Both sides of the two first springs 10 are connected with a first spring 10 by bolts, and the top outer walls of the two first springs 10 are connected with a fixed plate 12 by bolts, the top outer wall of the fixed plate 12 is provided with an inlet, and the inner wall of the inlet is connected with a Feed hopper 11, the outer wall of feed hopper 11 is provided with a plurality of filter holes 13 near the bottom position, the inner wall of filter box 1 is connected with support plate 16 by bolts near the position of the top, and both sides of support plate 16 top outer walls are A through opening 8 is opened, and the top outer wall of the support pla...

Embodiment 2

[0041] refer to Figure 4 , a filter device for the production of an environmentally friendly foam breaker. Compared with Embodiment 1, the outer wall of one side of the box cover 9 is connected with a vibrating motor 23 by bolts, which can filter the foam breaker adhered to the inner wall of the equipment. to process.

[0042]Working principle: when in use, the foam breaker that needs to be filtered is filled into the interior of the equipment through the feeding hopper 11, and the foam breaker is initially filtered through the filter hole 13, and the filtered foam breaker will fall into the splitter plate 15, so that the foam breaker is split through the splitter plate 15, so as to improve the filtration efficiency of the device for the foam breaker, and prevent the foam breaker from accumulating together to affect the filter efficiency of the foam breaker. The baffle rod 14 can It has a certain blocking effect on the foam breaker, so as to slow down the flow speed of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com