Laminated hollow fiber membrane element with equal membrane wire spacing and production method thereof

A production method and a technology for a laminated body, which are applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., and can solve problems such as the reduction of the usable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

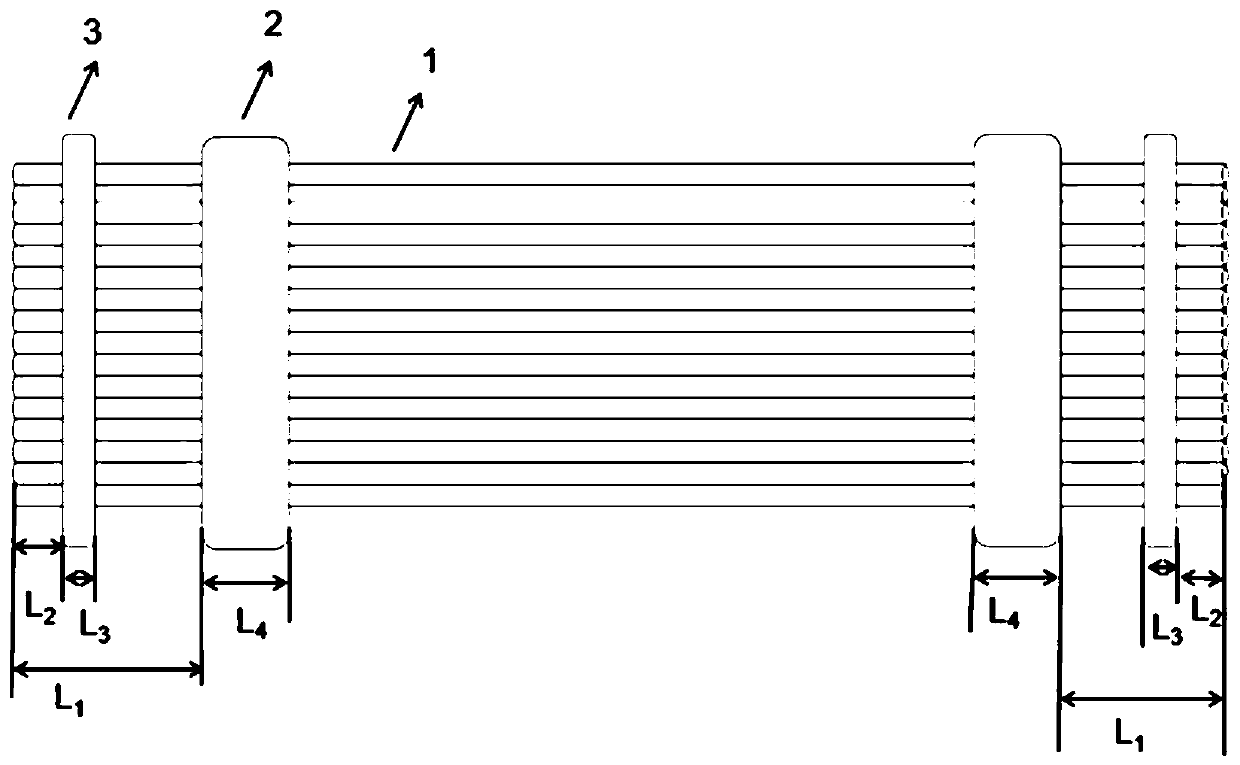

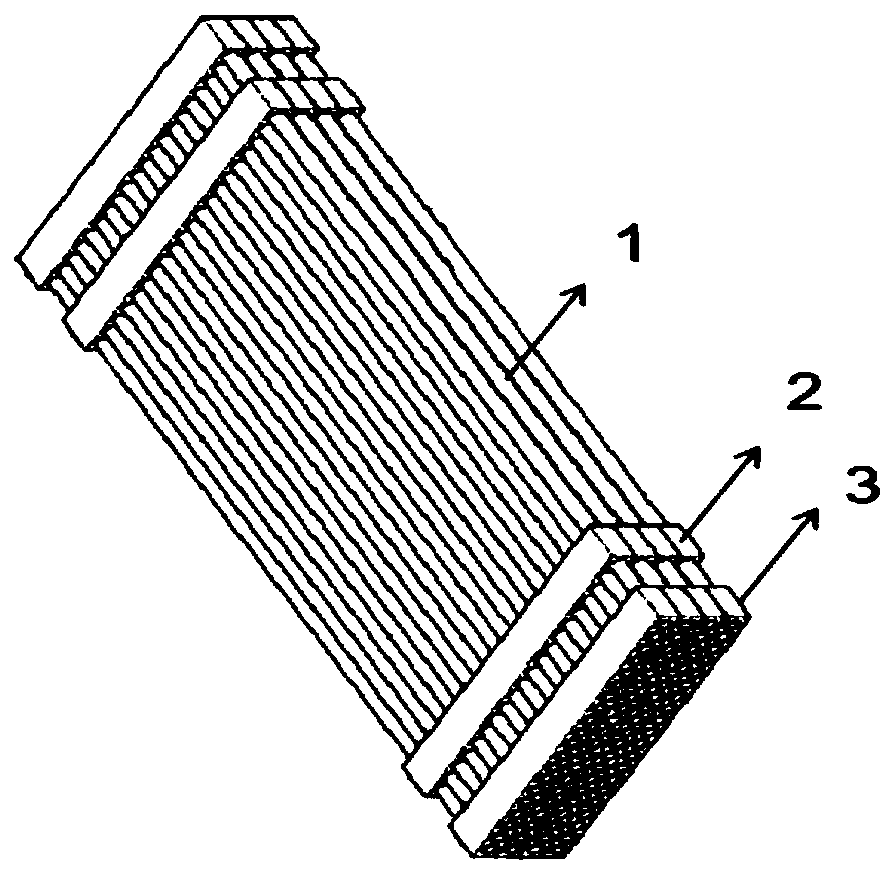

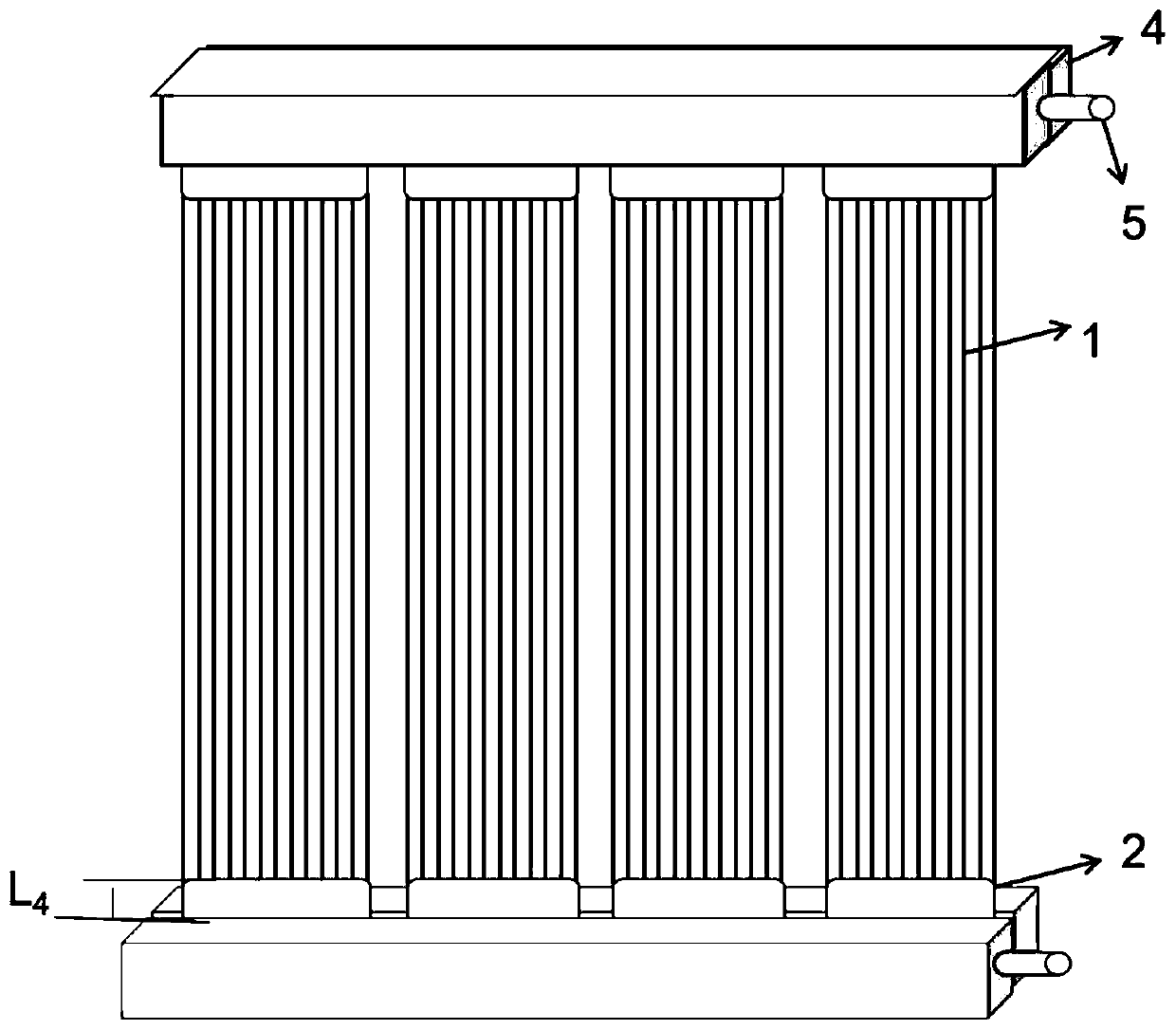

[0034] The hollow fiber membranes are arranged by mechanical arrangement, the number of membranes is 60, the outer diameter of the membranes is 2mm, and the distance between adjacent membranes is 1mm.

[0035] The first elastic body and the second elastic body are covered on the front and rear ends of the membrane filament array, wherein the first elastic body is closer to the middle of the membrane filament, and the second elastic body is closer to the end of the membrane filament. The covering thickness of the elastic body on the membrane filament is 1mm, wherein the distance between the first elastic body and the end of the membrane filament is L 1 The distance between the second elastic body and the end L2 of the membrane filament is 50 mm, the covering width of the first elastic body is 30 mm, and the covering width of the second elastic body is 10 mm. The elastomers are all made of polyamide (PA) materials with an elongation rate of 500%. The materials are covered on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com