Visible light catalyst, its preparation method and method for degrading pesticide pollutants

A technology for degrading pesticides and pollutants, applied in water pollutants, chemical instruments and methods, catalysts for physical/chemical processes, etc. The oxidation reaction process with pollutants, the effect of improving the degradation efficiency and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention discloses a preparation method of a visible light catalyst, comprising:

[0025] Adding polyvinylpyrrolidone solution and KMnO to the rGO dispersion 4 solution to obtain the first mixed solution;

[0026] maintaining the first mixed solution under the condition of a water bath at the first temperature for the first time to obtain a second mixed solution;

[0027] The second mixed solution is maintained at the second temperature for a second time and then lowered to obtain a γ-MnOOH-rGO composite material, which is the visible light catalyst.

[0028] In some embodiments of the present invention, the concentration of the rGO dispersion is 0.1-0.3 mol / L, such as 0.12 mol / L, 0.15 mol / L, 0.18 mol / L, 0.20 mol / L, 0.22 mol / L , 0.25mol / L, 0.28mol / L;

[0029] In some embodiments of the present invention, the concentration of the polyvinylpyrrolidone solution is 30-60g / L, such as 35g / L, 40g / L, 45g / L, 50g / L, 55g / L;

[0030] In some embodiments of the present inve...

Embodiment 1

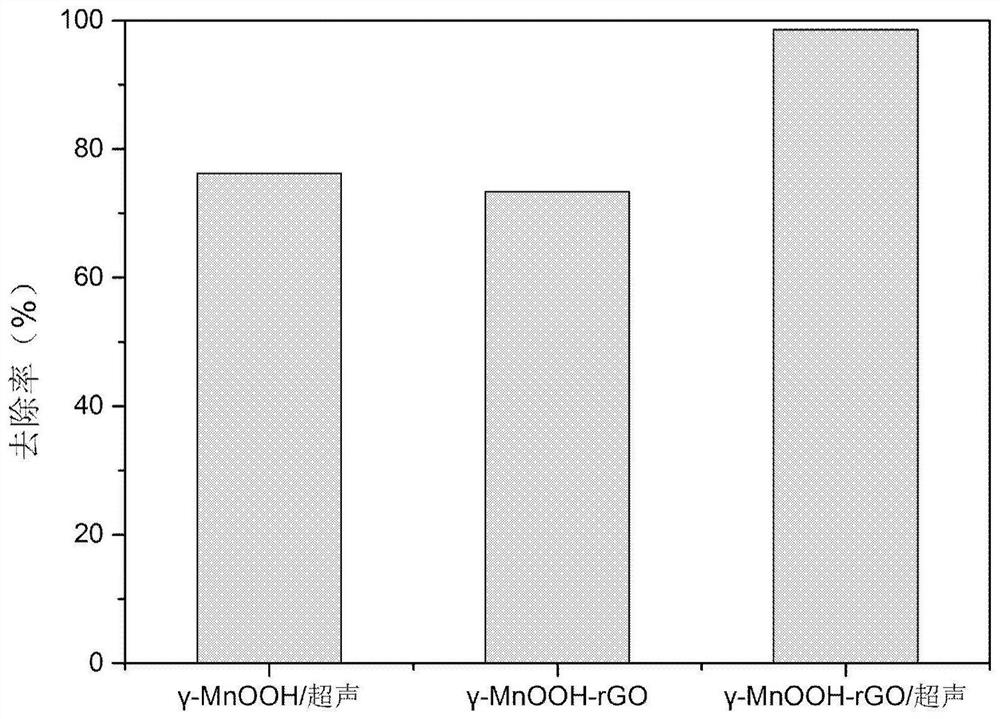

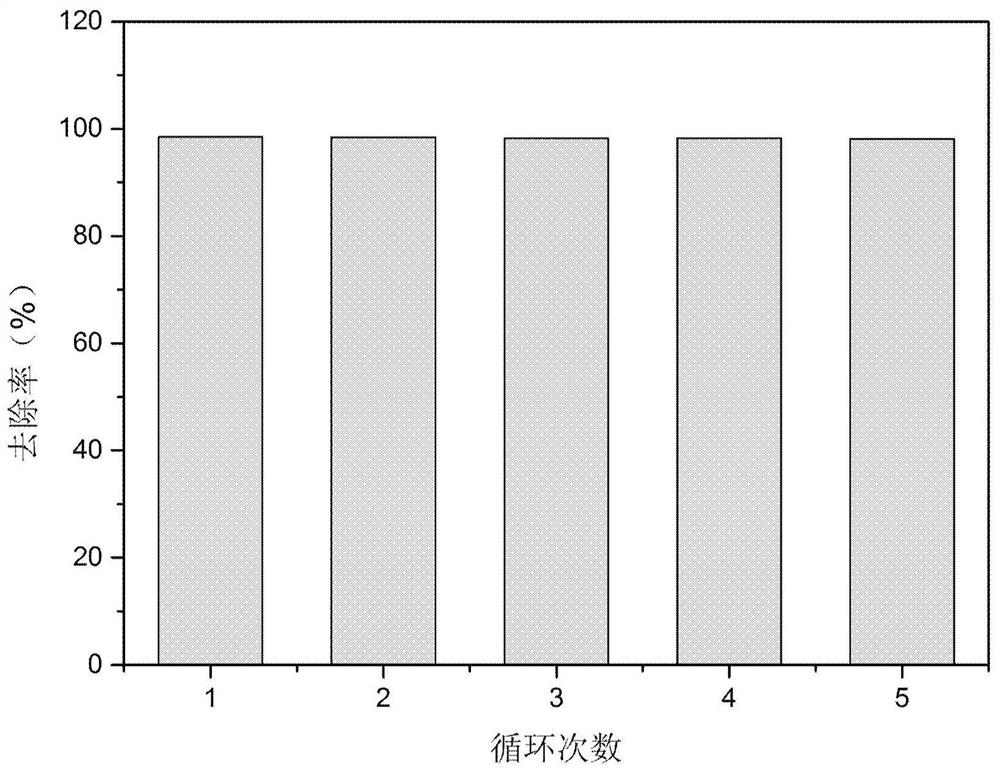

[0061] The preparation method of a visible light catalyst and the water treatment application assisted by ultrasound in this embodiment are carried out through the following steps:

[0062] 1. Preparation of rGO nanosheets: GO was treated in deionized water by ultrasonic treatment at 300W for 10min. At room temperature, ascorbic acid was added to the GO dispersion to obtain 80 mL of a mixed solution, wherein the concentration of GO in the mixed solution was 0.1 mol / L, and the concentration of ascorbic acid was 1 mmol / L; the pH of the solution was adjusted to 9 with 20% ammonia water. The mixture was maintained in a water bath at 90°C for 1 h, the suspension was filtered at 10 kPa, the collected suspended solids were washed 5 times with deionized water, and then dried in a vacuum oven at 60°C for 0.5 h.

[0063] 2. Preparation of γ-MnOOH-rGO composite photocatalyst: 80 mL of 0.1 mol / L rGO dispersion was prepared in deionized water, and 300 W ultrasonic treatment was performed f...

Embodiment 2

[0070] The preparation method of a visible light catalyst and the water treatment application assisted by ultrasound in this embodiment are carried out through the following steps:

[0071] 1. Preparation of rGO nanosheets: GO was treated in deionized water by ultrasonic treatment at 300W for 30min. At room temperature, ascorbic acid was added to the GO dispersion to obtain 80 mL of a mixed solution, wherein the concentration of GO in the mixed solution was 0.3 mol / L, and the concentration of ascorbic acid was 3 mmol / L; the pH of the solution was adjusted to 10 with 40% ammonia water. The mixture was maintained in a water bath at 90°C for 3 hours, the suspension was filtered at 50kPa, the collected suspended solids were washed 10 times with deionized water, and then dried in a vacuum oven at 80°C for 2 hours.

[0072] 2. Preparation of γ-MnOOH-rGO composite photocatalyst: 80 mL of 0.3 mol / L rGO dispersion was prepared in deionized water, and subjected to 300 W ultrasonic treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com