Fixtures for making offset pipe bodies for well completions

A technology of tooling fixtures and offset tubes, which is applied in the direction of manufacturing tools, feeding devices, positioning devices, etc., can solve the problems of cumbersome replacement of fixtures, unstable machining accuracy, and high technical requirements, and achieve convenient operation, simplified operation, and structural design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described now in conjunction with accompanying drawing.

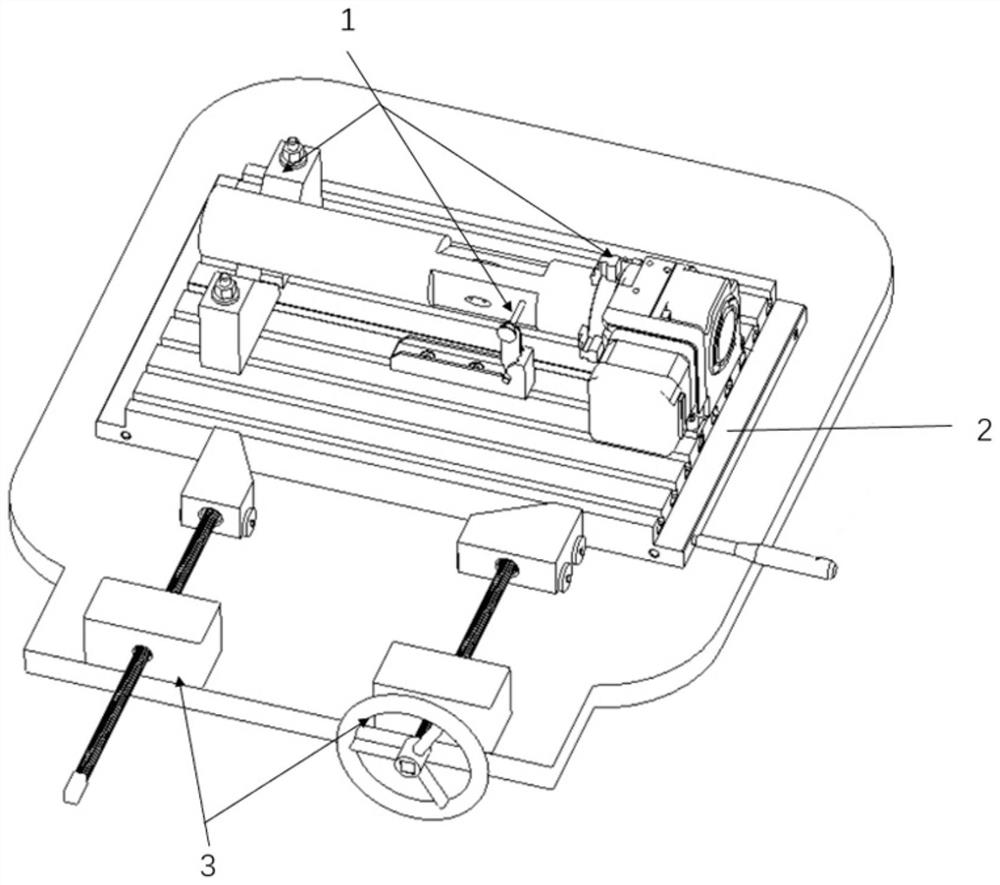

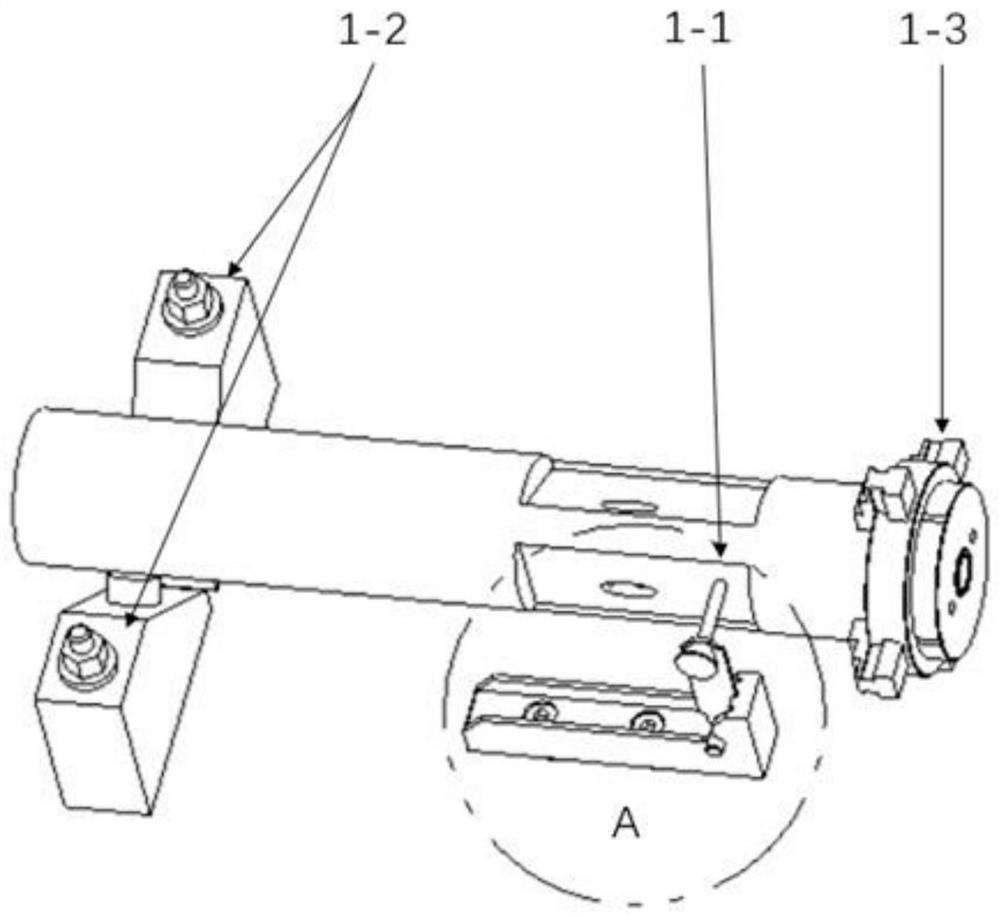

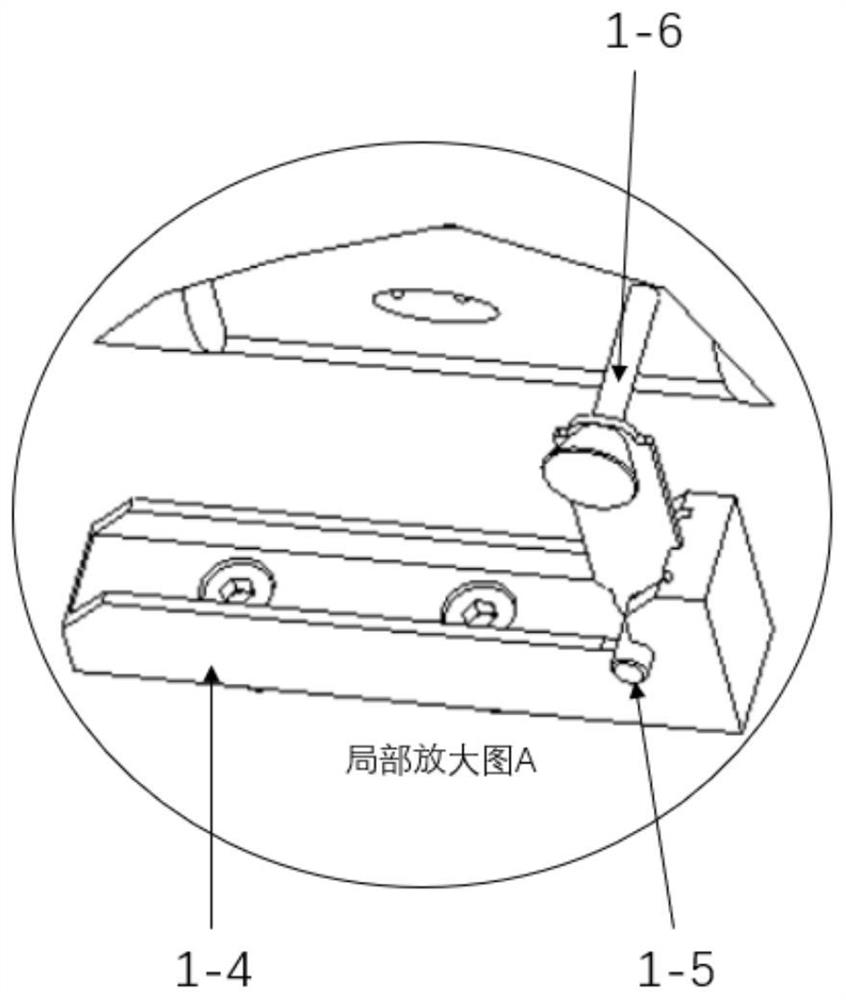

[0034] see Figure 1 to Figure 6 , Figure 1 to Figure 6 Shown is an embodiment of the present invention, which includes a clamping system 1 , an indexing system 2 and a limiting system 3 . The clamping system 1 includes a V-shaped support block 1-2 for placing the pipe body. First, the reference level ruler 1-1 is rotated around the pin shaft 1-5 from the ruler base 1-4 to stand up, and the pipe body is placed on the V-shaped support block 1-2, and one end is clamped by the four-jaw chuck 1-3. tight.

[0035] The indexing system includes an X-axis rotation positioning mechanism 2-1, which controls the rotation of the tube around its central axis by driving a four-jaw chuck 1-3. The X-axis rotary positioning mechanism 2-1 uses an electric control four-jaw chuck 1-3 to complete the rotation and positioning of the workpiece around the X-axis (ie, the central axis of the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com