An AI-based automatic weld path recognition method

A path recognition and automatic technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high manpower cost and time cost, inability to effectively guarantee welding quality, adjust welding parameters, etc., and achieve reduction Scrap rate, reduction of programming and teaching process, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

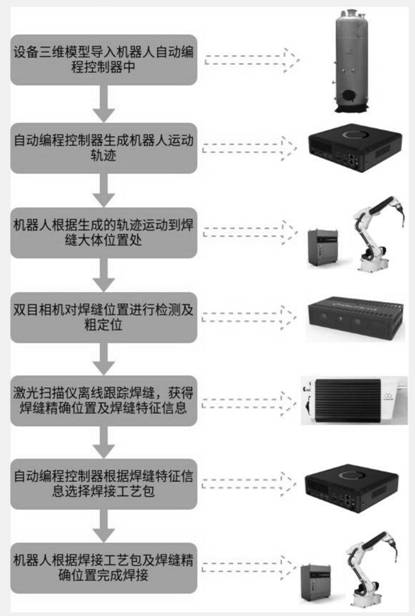

[0016] The concrete operation method when the present invention is used is:

[0017] 1. Import the 3D model data of the workpiece to be welded into the welding robot controller. The 3D model data of the imported workpiece includes the overall structure of the workpiece to be welded and the position information of the weld in the workpiece;

[0018] 2. Install the workpiece to be welded on the welding tooling table, and take a picture of the workpiece as a whole through the stereo camera fixed above the table, which is used to detect whether the position and posture of the welding workpiece on the table are correct. Manual confirmation is required on site. All equipment is safe and ready.

[0019] 3. The automatic programming controller of the welding robot generates offline the motion trajectory of the welding robot to complete the entire welding process of the workpiece according to the 3D model data of the equipment, the position information of the welding seam and the model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com