SMW construction method pile section steel fixing device and construction method

A technology of fixing device and construction method pile, which is applied in the direction of excavation, sheet pile wall, foundation structure engineering, etc., can solve the problems of large center deviation of construction products, large deviation of the verticality of interpolated H-beams, and increased safety hazards, etc. The effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

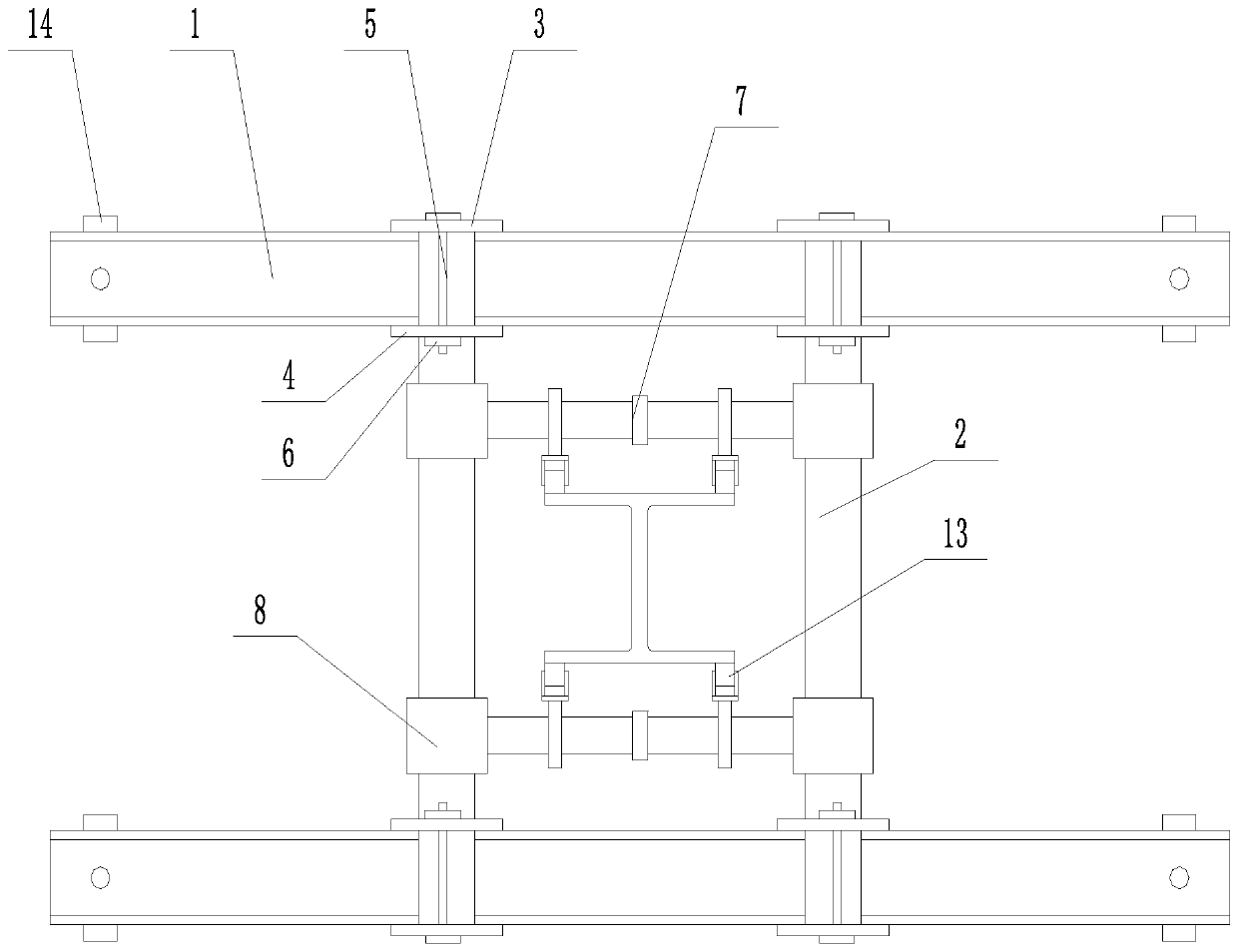

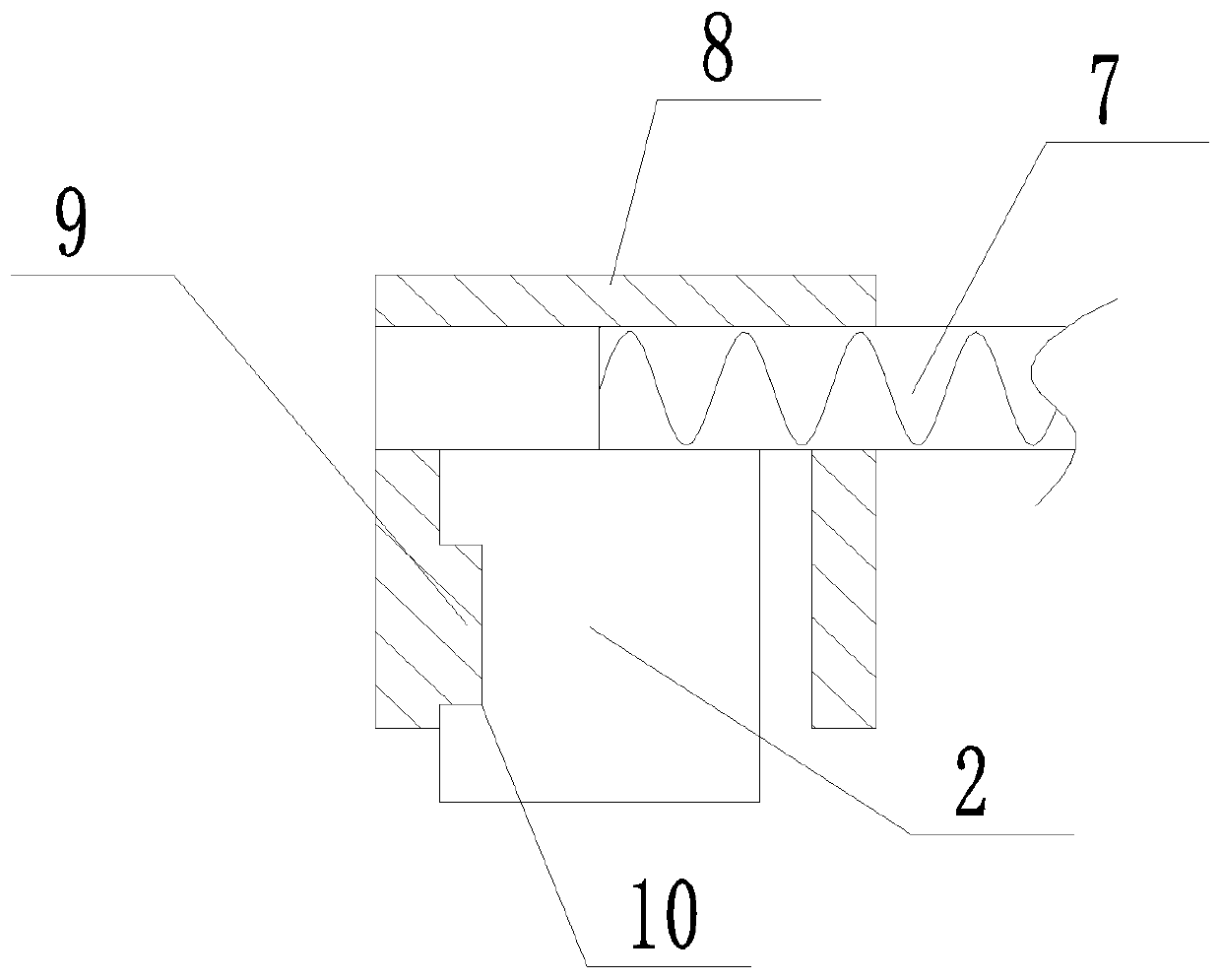

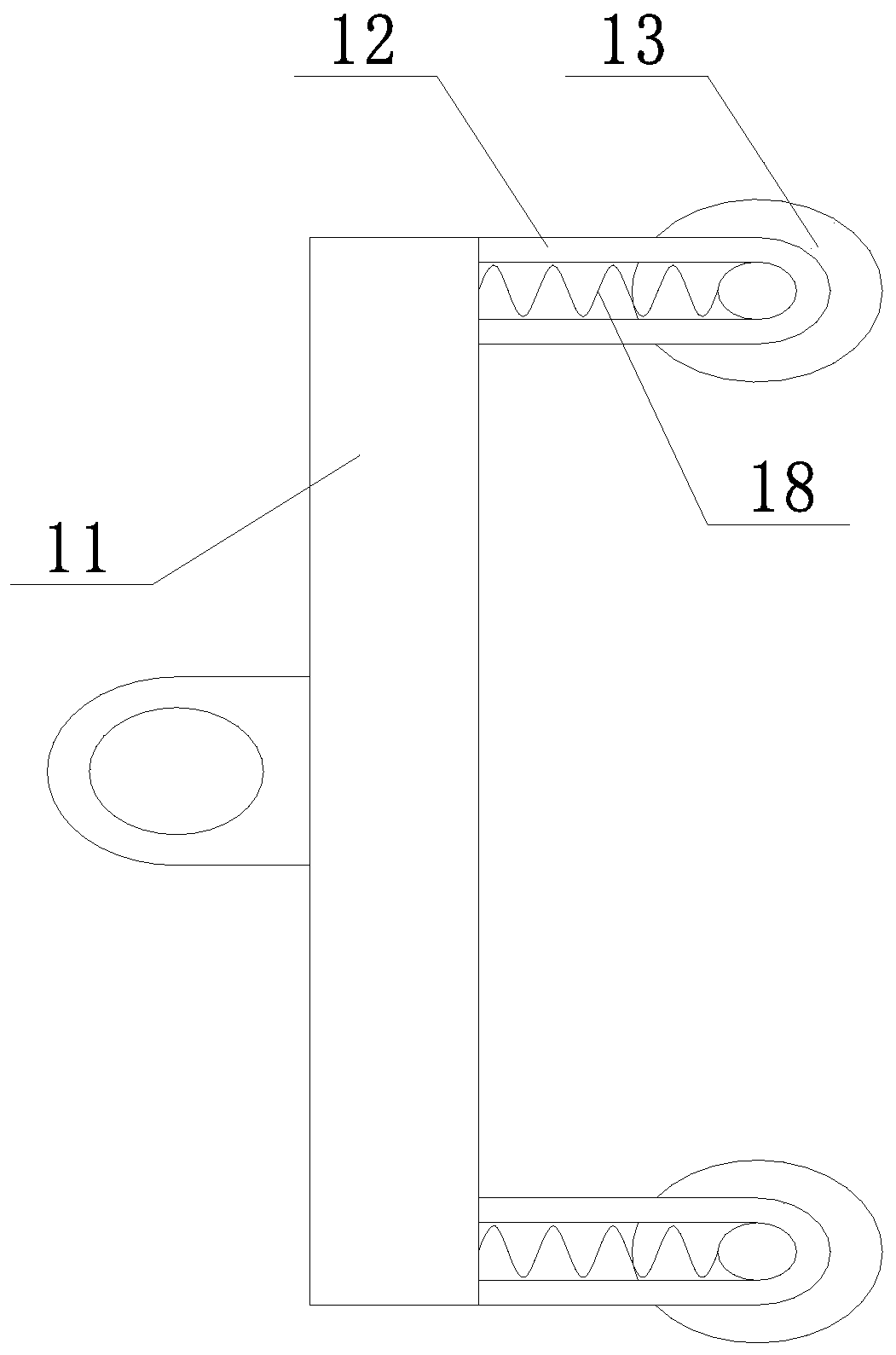

[0030] Such as Figure 1 to Figure 3 As shown, a SMW construction method pile-shaped steel fixing device includes a guide beam 1, two guide beams 1 are arranged in parallel, a positioning mechanism is arranged between the two guide beams 1, and the positioning mechanism includes an adjustment assembly 1 and an adjustment assembly 2. The first assembly can be adjusted between the two guide beams 1, and the second adjustment assembly can be adjusted on the first adjustment assembly. The position is fixed through the adjustment assembly one and the second adjustment assembly pair of profile steel. Use the adjustment component one to slide to any position on the guide beam 1, while ensuring the distance between the two guide beams 1, and then combine the adjustment component two to make the profiled steel be positioned horizontally and longitudinally. The second adjusting component is inserted vertically to ensure its precise positioning.

[0031] In a further preferred solution of ...

Embodiment 2

[0035] Such as Figure 4 As shown, it is further improved on the basis of embodiment 1. The bottom of the guide beam 1 is provided with a leveling assembly. The leveling assembly includes a support base 14, a rotating rod 15 and a bottom plate 16. The support base 14 and the guide beam 1 are detachably connected, Two rotating rods 15 are provided symmetrically. One end of the rotating rod 15 is rotatably connected to the bottom surface of the support base 14, and the other end of the rotating rod 15 is slidably connected to the bottom plate 16. The rotating rod 15 is provided with a fixing device for fixing with the bottom plate 16. Locking pieces. The height of the support base 13 is adjusted by rotating the rotating rod 15 while the guide beam 1 is leveled. At the same time, the bottom of the rotating rod 15 and the bottom plate 16 slide, and then the bottom plate 16 is connected to the bottom plate 16 by the locking member on the rotating rod 15 Rotate the rod 15 to achieve ...

Embodiment 3

[0038] A construction method of SMW construction method pile-shaped steel fixing device includes the following steps:

[0039] S1. Installation of guide beam 1: excavate the SMW construction method pile construction guide trench according to the drawing, place leveling components on both sides of the guide trench according to the positioning device, and fix the guide beam 1 on the support base 14 of the leveling component by bolts, and Adjust the rotating rod 15 until the guide beam 1 is in a horizontal state, and then connect and fix the rotating rod 15 with the bottom plate 16 through a locking piece. The center line of the leveling components on both sides is the center line of the positioning tool;

[0040] S2. Installation of adjustment assembly 1 and adjustment assembly 2: The two connecting rods 2 are placed flat on the guide beam 1, and the two ends of the adjusting member 7 are connected to the corresponding positioning blocks 8 respectively, and the connecting rod 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com