Drilling machine equipment with synchronous extraction function for coal mine production

A kind of function, coal mine technology, applied in the field of drilling rig equipment with synchronous extraction function, can solve the problems of increasing device cost, easy to break, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

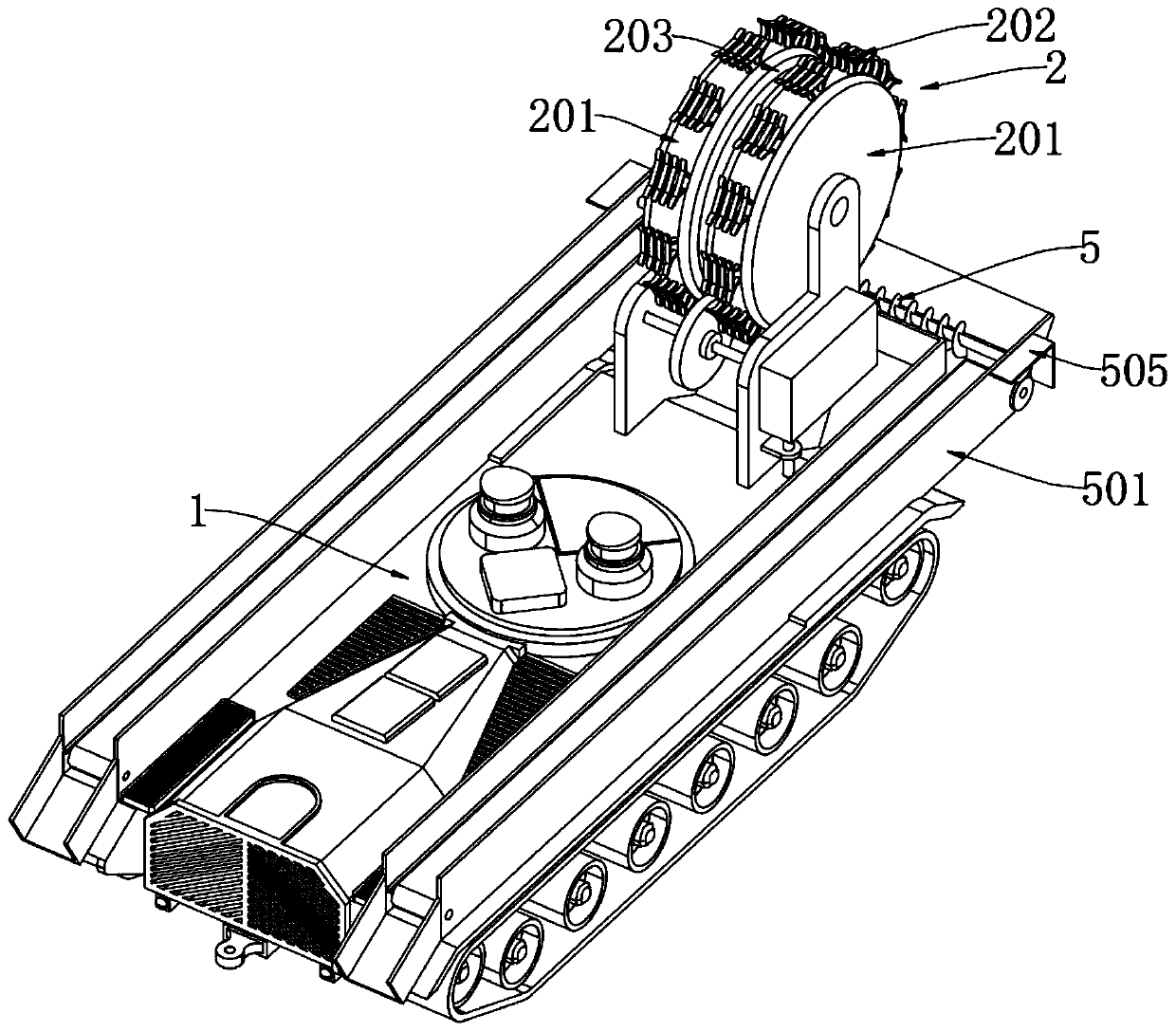

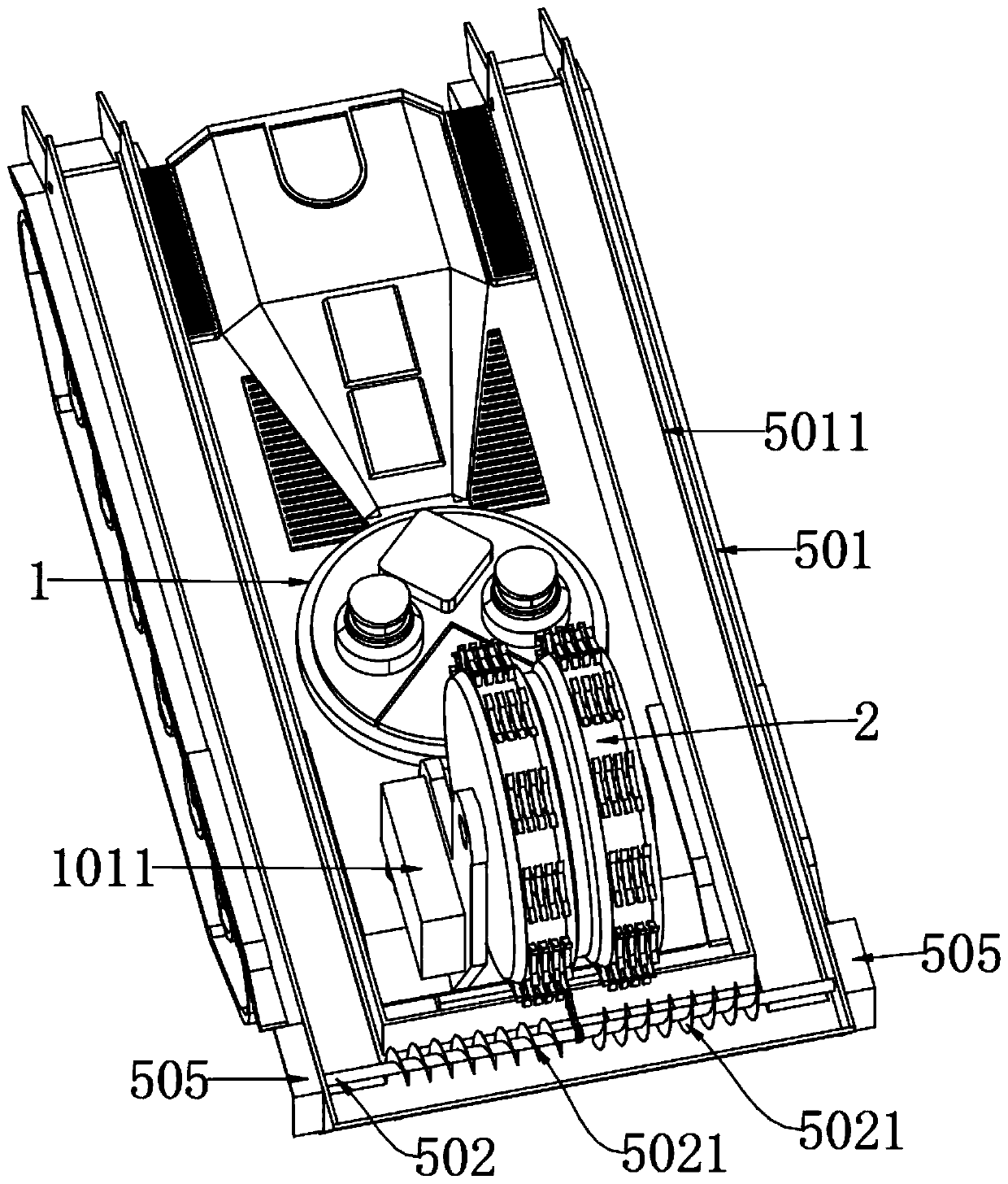

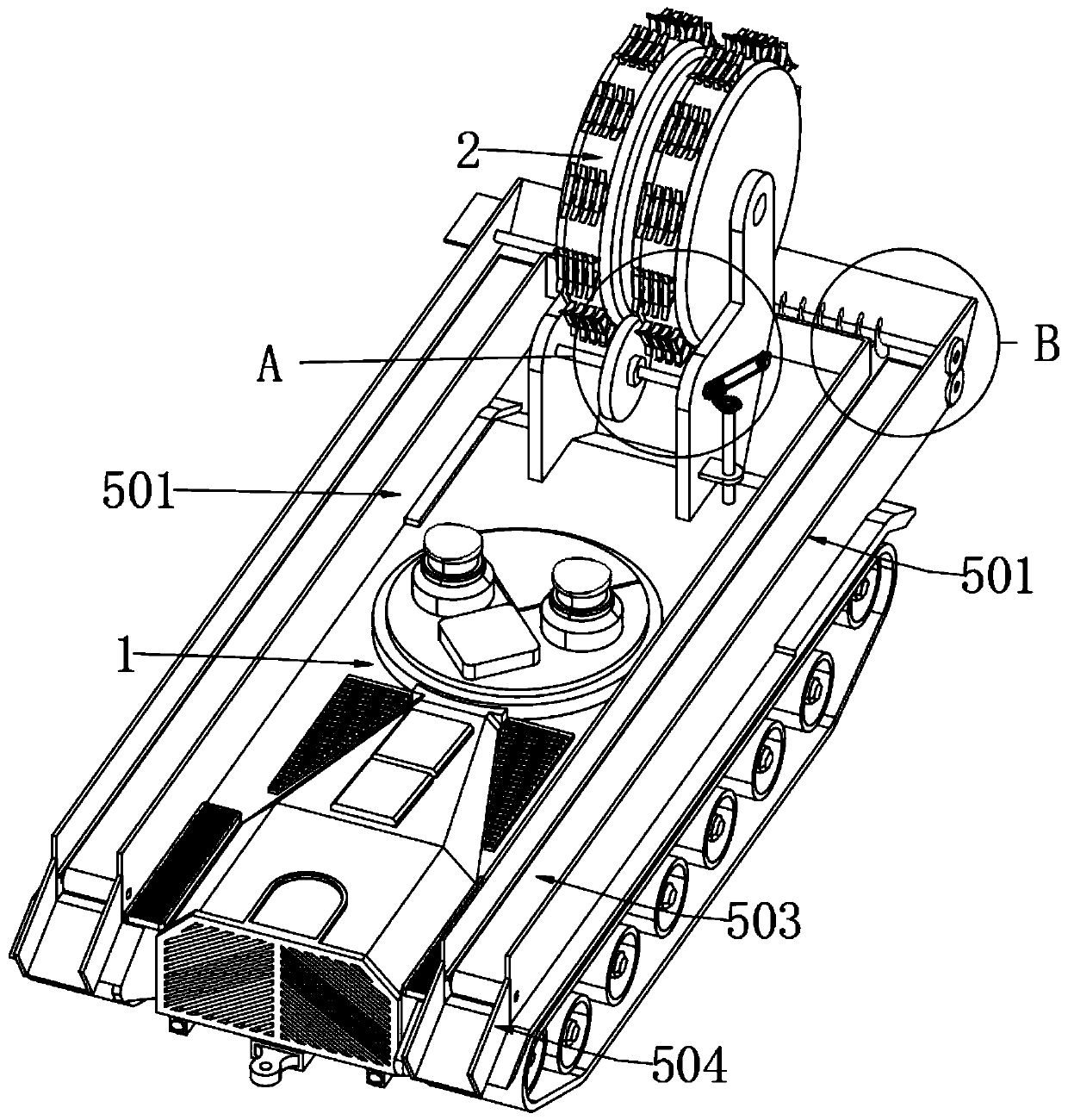

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The present invention provides a drilling rig equipment with synchronous extraction function for coal mine production, which includes a coal shoveling mechanism 2; The front end of the machine body 1 and the front connecting support plate 101 are also rotatably inlaid with the transverse drive shaft 301 and the transition shaft 4, and the transverse drive shaft 301 and the transition shaft 4 are connected by chain transmission and are respectively arranged on the rear side of the coal shoveling mechanism 2 On the lower side, the outer end of the horizontal drive shaft 301 is fixedly equipped with a horizontal bevel gear 3011, and the horizontal bevel gear 3011 is engaged with the vertical bevel gear 1021, and the vertical bevel gear 1021 is fixedly installed on the top of the vertical drive shaft 102, and The bottom end of the vertical drive shaft 102 is connected to the drive motor inside the body 1. The drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com