Small and medium-size triangular rotor engine double oil injection system

A triangular rotor and fuel injection system technology, applied in engine components, engine control, combustion engine, etc., can solve problems such as poor atomization, low combustion efficiency, large weight and volume, etc., to improve power-to-weight ratio and solve fog The effect of not melting well and speeding up the speed of flame propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

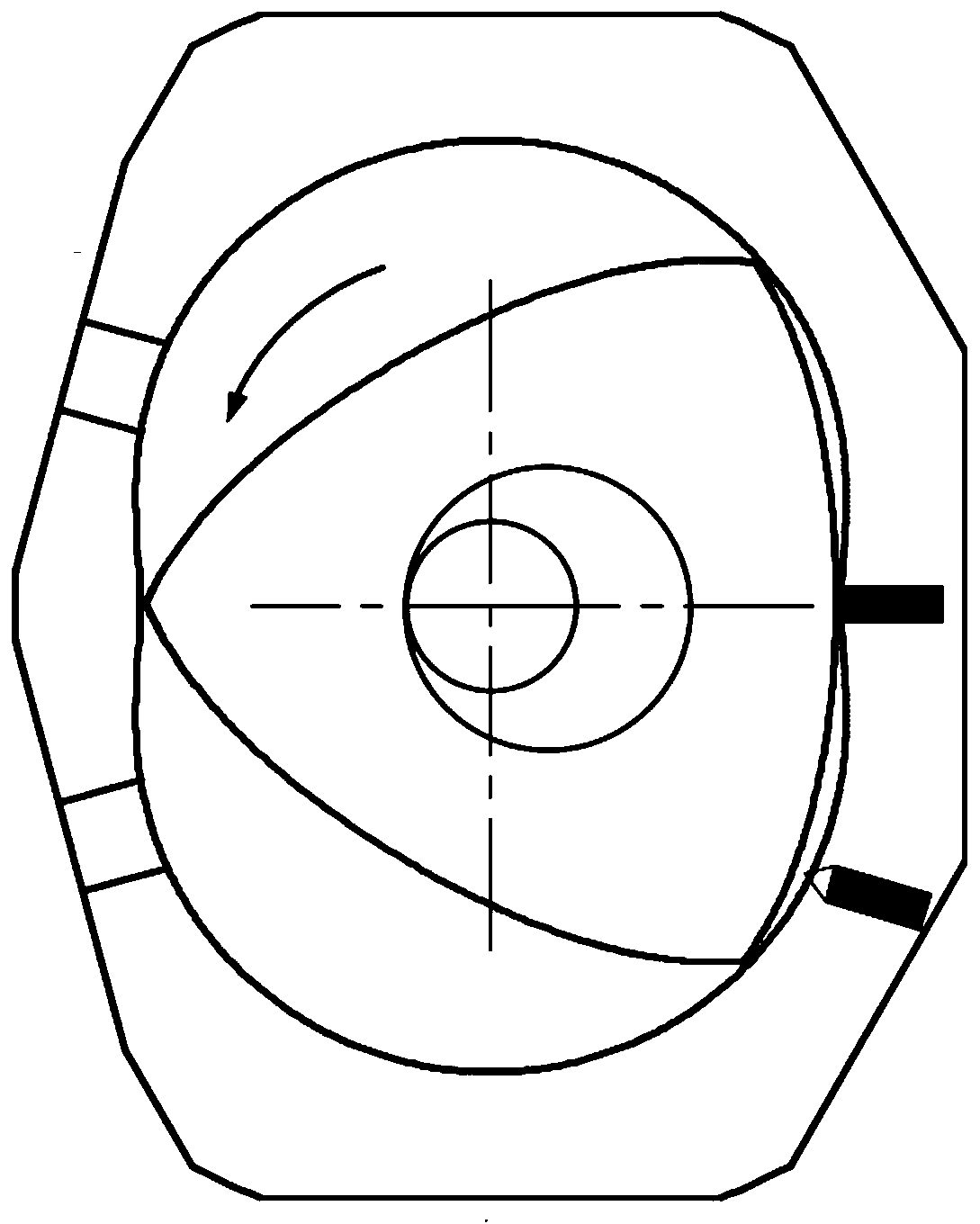

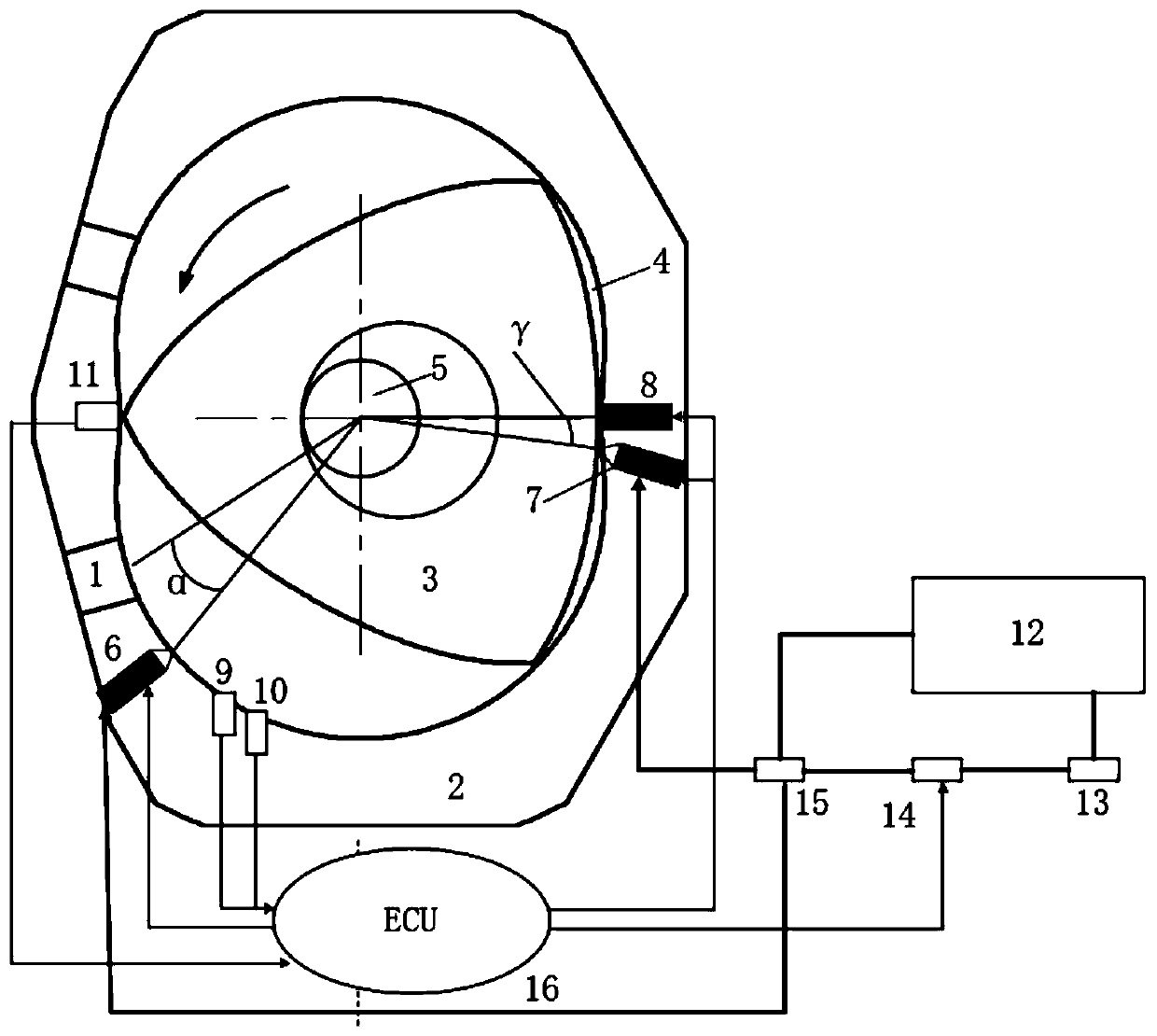

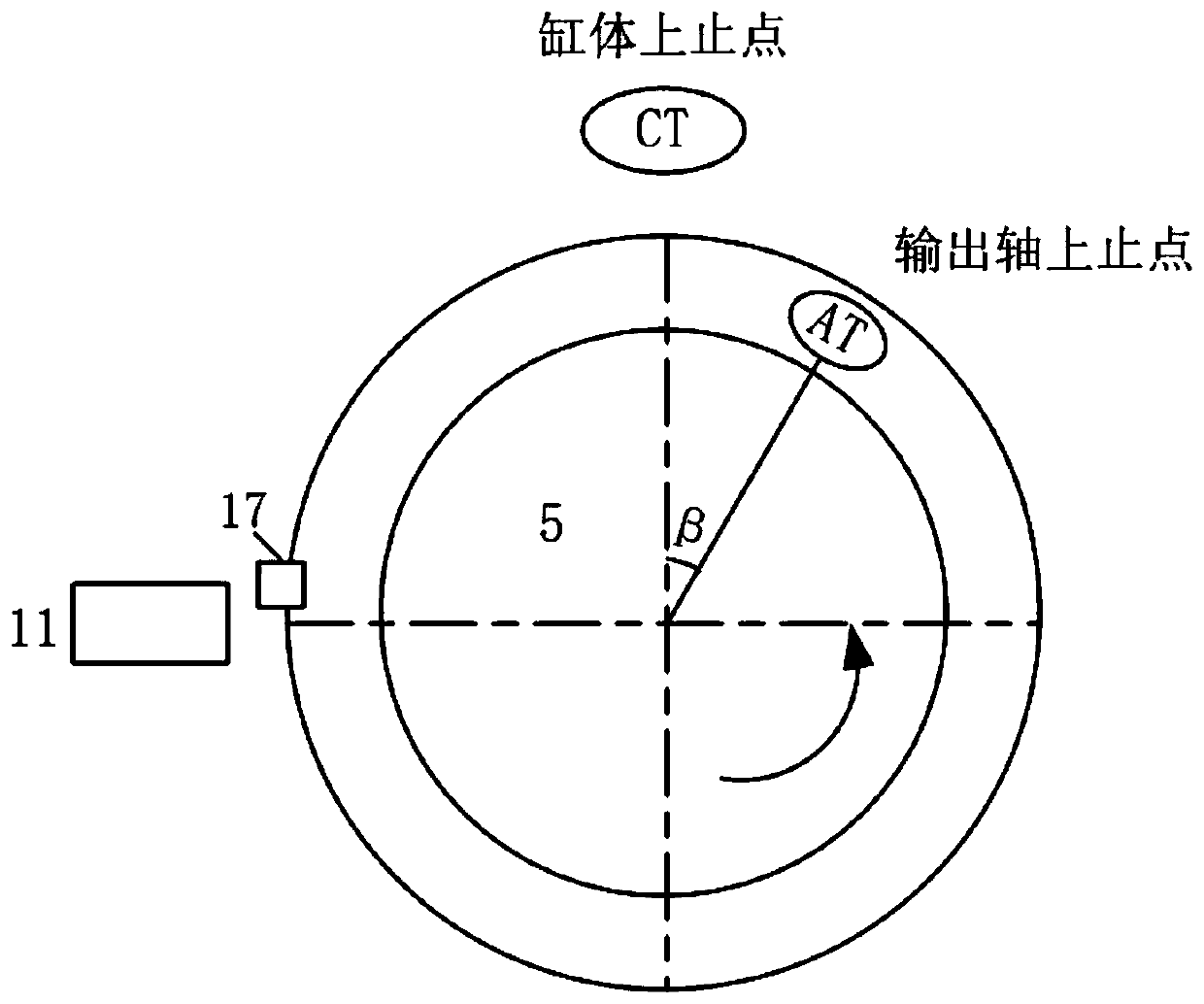

[0041] figure 2 Shown is a kind of small and medium sized kerosene triangular rotor engine double fuel injection system disclosed by the present invention, including triangular rotor engine, oil supply system, spark plug 8 and electronic control ECU16; It is characterized in that: on the side wall of triangular rotor engine cylinder 2 Two fuel injector installation holes are opened for installing the first fuel injector 6 and the second fuel injector 7 respectively; the first fuel injector 6 is located near the intake passage 1; the second fuel injector 7 is close to the spark plug 8. The kerosene injected by the second fuel injector 7 is used for ignition; it also includes an in-cylinder temperature sensor 9, an in-cylinder pressure sensor 10, a Hall sensor 11, a magnet 17, a fuel tank 12, a fuel filter 13, and an oil pump 14 and fuel pressure regulator 15.

[0042] The specific installation position of the first fuel injector is determined by the environment in the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com