Steel-aluminum composite pipe and manufacturing method thereof

A steel-aluminum composite and manufacturing method technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipes, etc., can solve the problems of poor bonding strength, low matching accuracy, low production efficiency, etc., and achieve high production efficiency and improve composite Strength, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

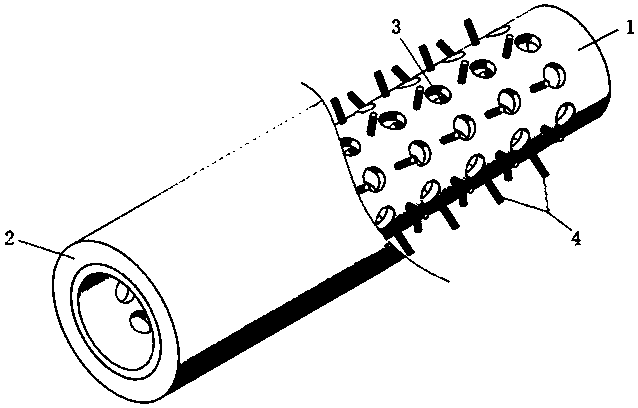

[0031] to combine figure 1 , the present invention is a steel-aluminum composite pipe, which is a bimetallic composite pipe, comprising a seamless steel pipe 1 and an aluminum pipe 2 poured outside the seamless steel pipe 1 . A threaded hole 3 penetrating through the side wall of the seamless steel pipe 1 is provided on the pipe wall of the seamless steel pipe 1 . The axial direction of the threaded hole 3 is arranged along the radial direction of the seamless steel pipe 1 . Threads are provided on the side walls of the threaded holes 3 . The inner wall of the aluminum tube 2 is filled with the threaded hole 3 . A screw 4 is welded to the outer wall of the seamless steel pipe 1 . Screw teeth are provided on the outer surface of the screw 4 . The screw 4 penetrates into the aluminum tube 2 . In this embodiment, there is no specific limitation on the number and positions of the threaded holes 3 and the screws 4 .

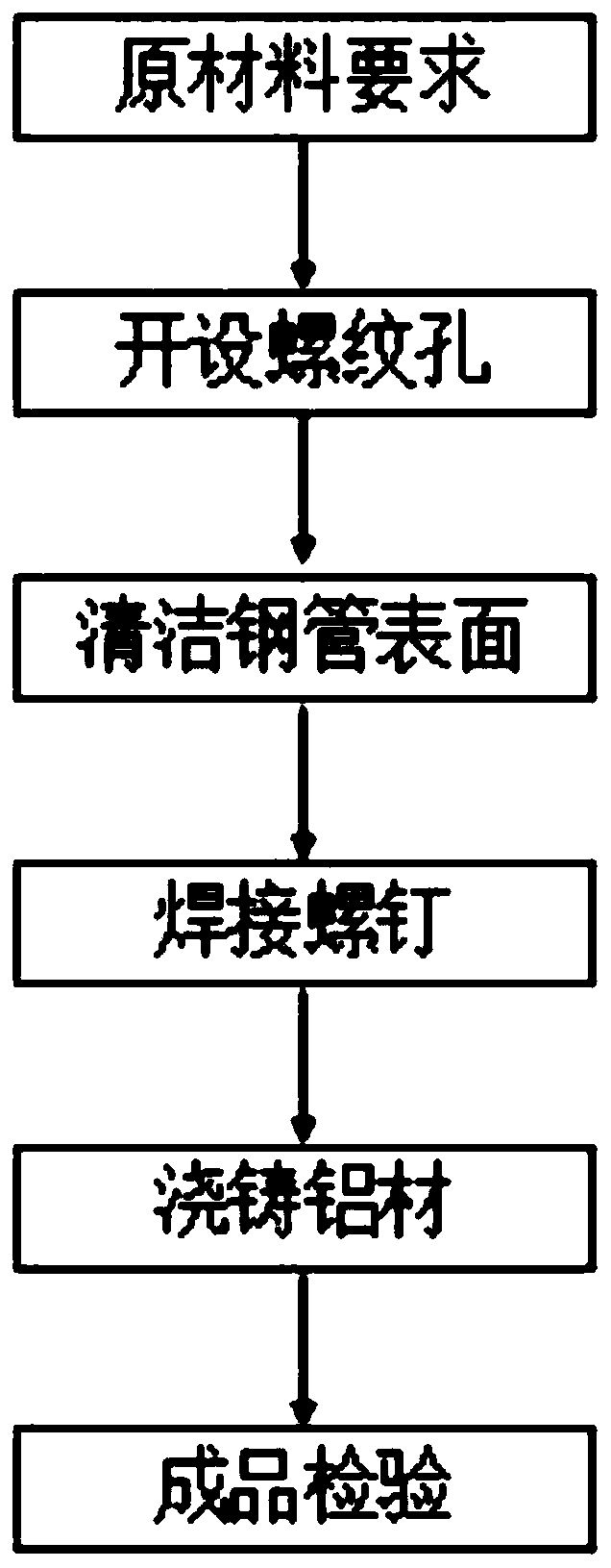

[0032] to combine figure 2 and image 3 , the manufactu...

Embodiment 2

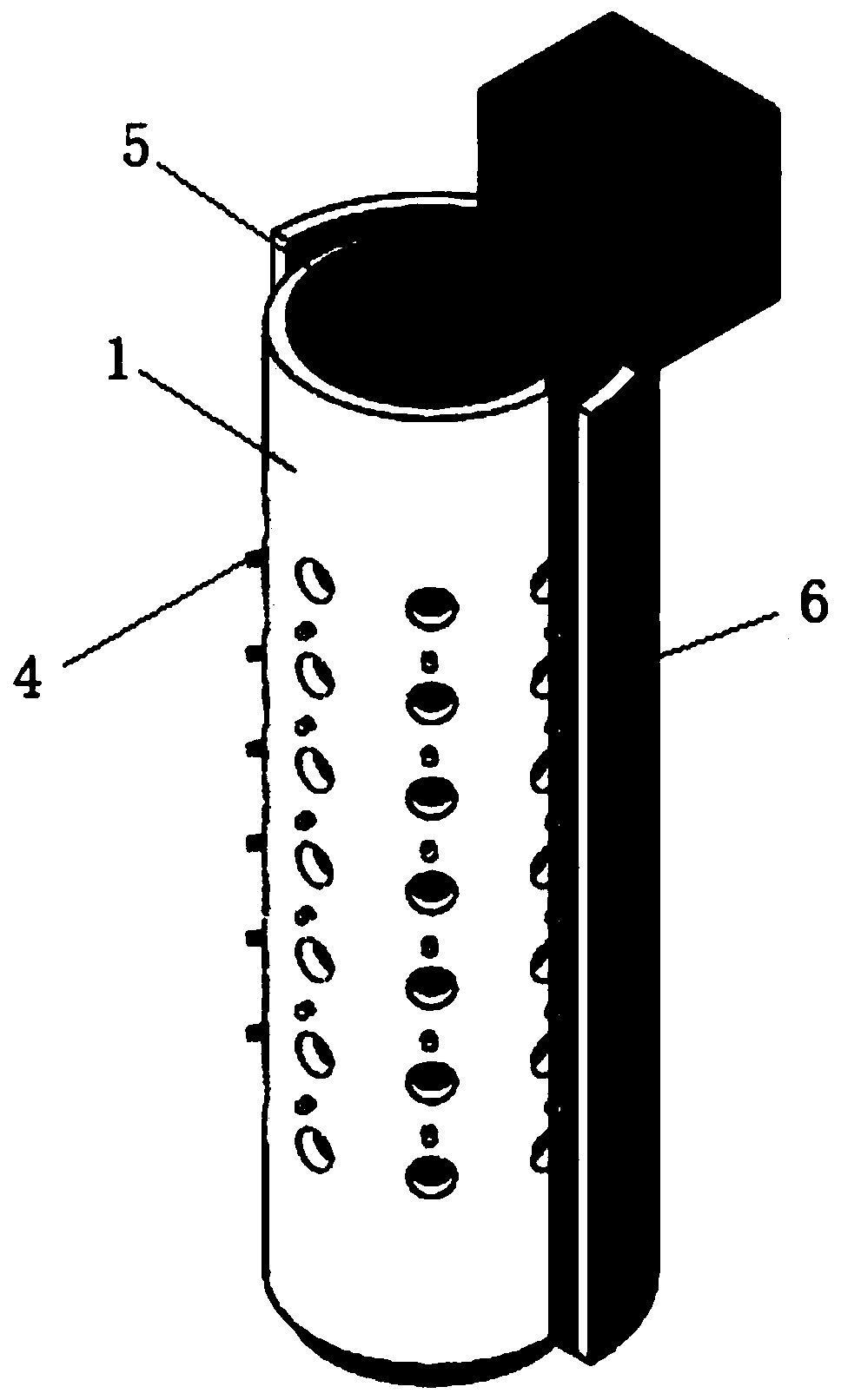

[0040] The difference between this embodiment and Embodiment 1 is mainly reflected in the optimization of the seamless steel pipe 1 .

[0041] The invention is a steel-aluminum composite pipe, which is a bimetallic composite pipe, comprising a seamless steel pipe 1 and an aluminum pipe 2 poured outside the seamless steel pipe 1 . A threaded hole 3 penetrating through the side wall of the seamless steel pipe 1 is provided on the pipe wall of the seamless steel pipe 1 . The axial direction of the threaded hole 3 is arranged along the radial direction of the seamless steel pipe 1 . Threads are provided on the side walls of the threaded holes 3 . The inner wall of the aluminum tube 2 is filled with the threaded hole 3 . A screw 4 is welded to the outer wall of the seamless steel pipe 1 . Screw teeth are provided on the outer surface of the screw 4 . The screw 4 penetrates into the aluminum tube 2 . Element content in carbon steel: wC≤0.255%, wP≤0.035%, wS≤0.035%. The steel o...

Embodiment 3

[0049] This embodiment is an optimization scheme based on Embodiment 1, and is mainly optimized for the threaded hole 3 and the screw 4 .

[0050] combine figure 1 , the present invention is a steel-aluminum composite pipe, which is a bimetallic composite pipe, comprising a seamless steel pipe 1 and an aluminum pipe 2 poured outside the seamless steel pipe 1 . A threaded hole 3 penetrating through the side wall of the seamless steel pipe 1 is provided on the pipe wall of the seamless steel pipe 1 . The axial direction of the threaded hole 3 is arranged along the radial direction of the seamless steel pipe 1 . Threads are provided on the side walls of the threaded holes 3 . The inner wall of the aluminum tube 2 is filled with the threaded hole 3 . A screw 4 is welded to the outer wall of the seamless steel pipe 1 . Screw teeth are provided on the outer surface of the screw 4 . The screw 4 penetrates into the aluminum tube 2 . In this embodiment, there is no specific limit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap