Graded control and running method of No.0 high-pressure heater of power plant set

A power plant unit, hierarchical control technology, applied in separation methods, control systems, chemical instruments and methods, etc., can solve problems such as lack of comprehensive consideration, contradiction between economy and safety, and inability to effectively take into account, to ensure safety, The effect of improving the overall level of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

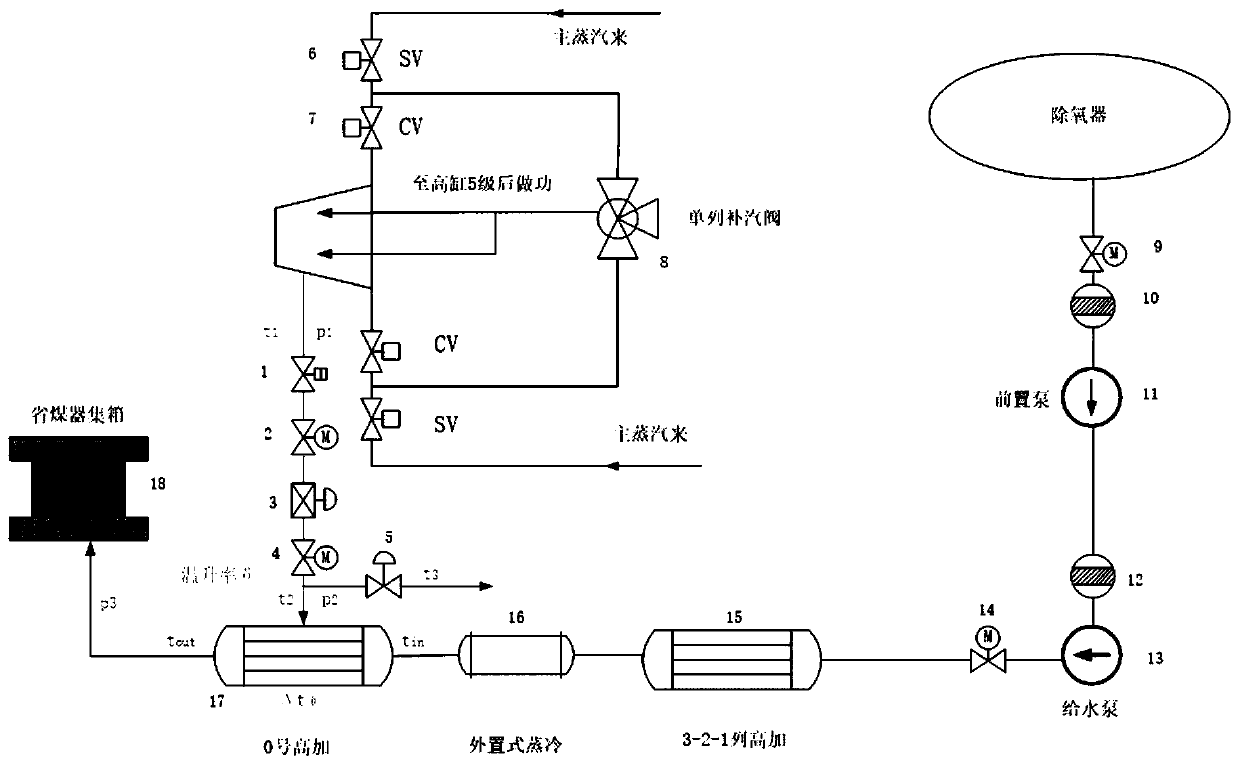

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0050] Such as figure 1 Shown: According to the normal start-up requirements of the unit, firstly, the feed water in the deaerator is boosted by the front pump 11 and the feed water pump 13, and then enters the high-pressure heater, and then passes through 3-2-1 15-row high-heat generator and external steam cooling step by step device 16, and finally the feed water enters the No. 0 high-heater and 0-exhaust steam for heat exchange, so as to increase the outlet water temperature t of the No. 0 high-power out . 0 The extraction steam is taken from the 5th stage rear extraction port of the high pressure cylinder, the parameter is p 1 , t 1 The steam passes through the 0 pump check valve 1, the 0 pump electric valve 2, the 0 pump pipeline regulating valve 3 and the 0 high steam inlet electric valve 4, and finally enters the 0 high heat to complete the steam-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com