PE valve airtightness test device

A test device and air tightness technology, applied in the field of PE valves, can solve the problems of low work efficiency, damage to PE valves, large errors, etc., and achieve the effects of simple structure, high detection efficiency, and high operation level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

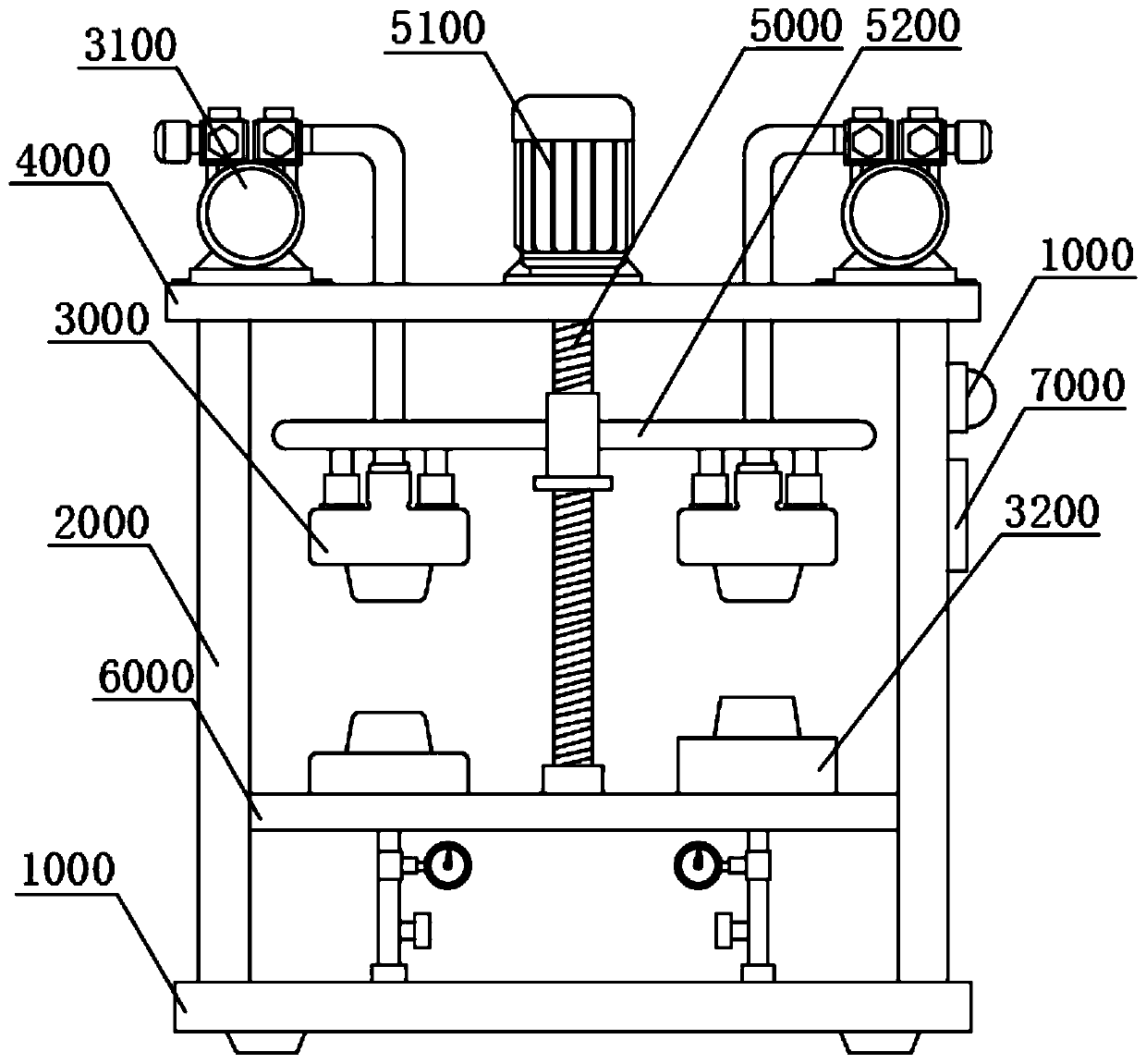

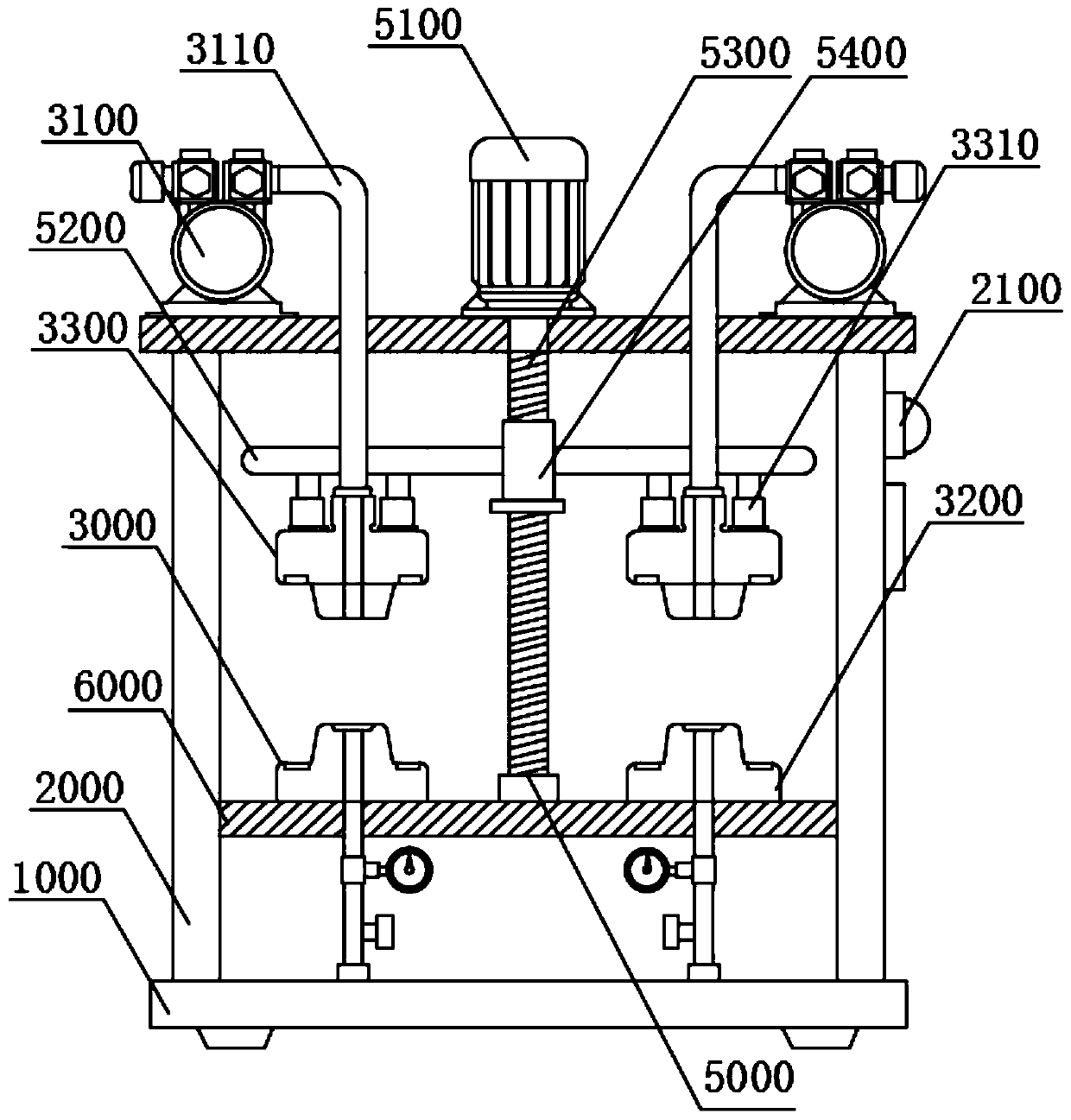

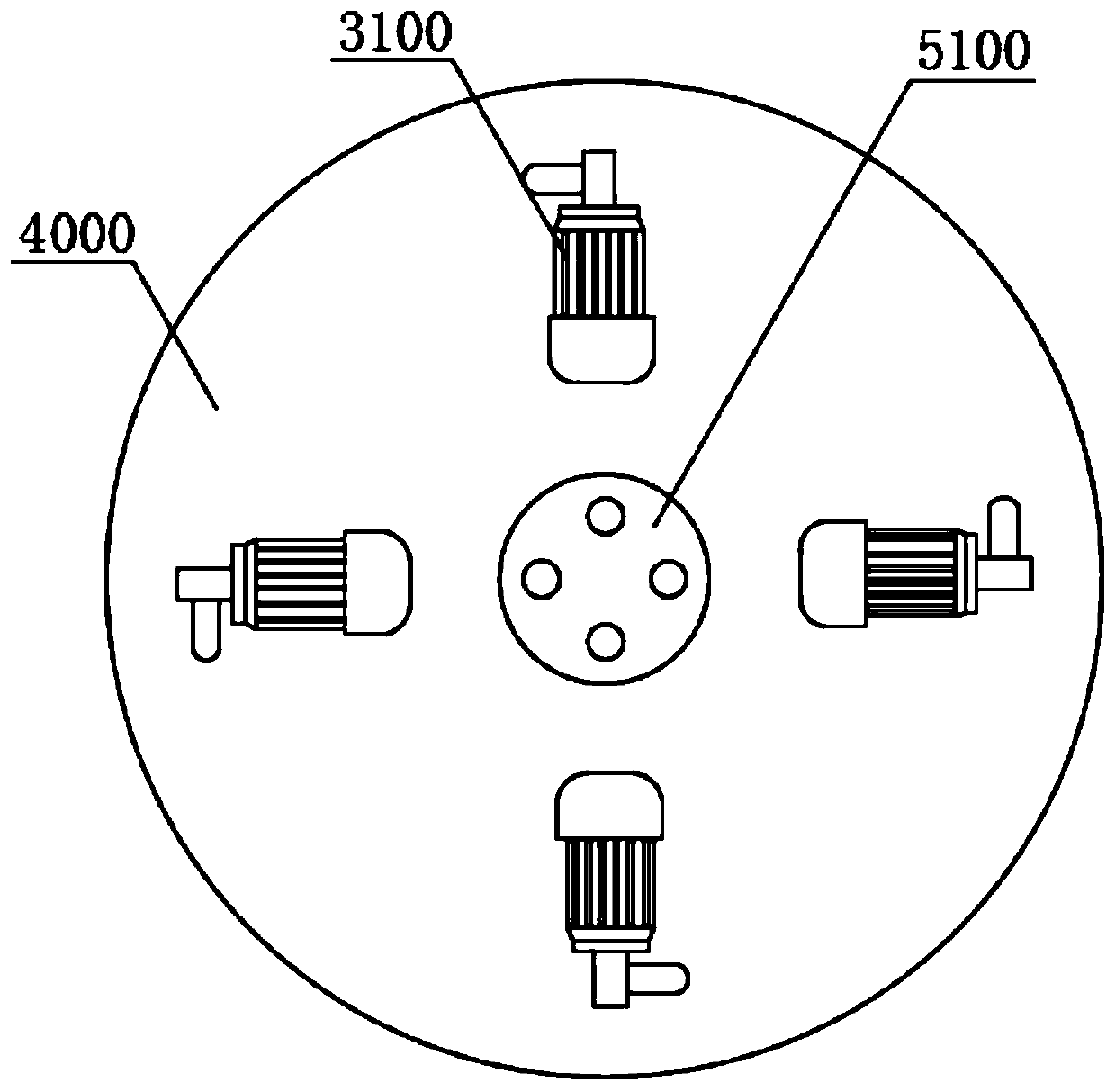

[0044] see Figure 1-6 , The present invention provides a technical solution: a PE valve airtightness test device, including: a bottom plate 1000, a support rod 2000, a test mechanism 3000, a top plate 4000, a clamping mechanism 5000 and a PLC controller 7000.

[0045] Wherein, both the bottom plate 1000 and the top plate 4000 have a circular structure.

[0046] Further, the bottom plate 1000 and the top plate 4000 may be made of iron, steel, stainless steel and other metal materials or alloy materials.

[0047] Wherein, there are four support rods 2000 .

[0048] Further, the support rod 2000 can be made of iron, steel, stainless steel and other metal materials or alloy materials.

[0049] Among them, four of the support rods 2000 are fixedly connected around the top of the bottom plate 1000, the top plate 4000 is fixedly connected to the top of the four support rods 2000, the test mechanism 3000 is fixedly installed on the inside of the support rod 2000, and the PLC The c...

Embodiment 2

[0076] see figure 1 , figure 2 and Figure 7 , The present invention provides a technical solution: a PE valve airtightness test device, including: a bottom plate 1000, a support rod 2000, a test mechanism 3000, a top plate 4000, a clamping mechanism 5000 and a PLC controller 7000.

[0077] Wherein, both the bottom plate 1000 and the top plate 4000 have a circular structure.

[0078] Further, the bottom plate 1000 and the top plate 4000 may be made of iron, steel, stainless steel and other metal materials or alloy materials.

[0079] Wherein, there are four support rods 2000 .

[0080] Further, the support rod 2000 can be made of iron, steel, stainless steel and other metal materials or alloy materials.

[0081] Among them, four of the support rods 2000 are fixedly connected around the top of the bottom plate 1000, the top plate 4000 is fixedly connected to the top of the four support rods 2000, the test mechanism 3000 is fixedly installed on the inside of the support rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com