Lens with thin film microstructure and preparation method of microstructure coating

A microstructure and lens technology, applied in glasses/goggles, instruments, optics, etc., can solve the problems of increasing processing costs, achieve the effect of reducing production costs and enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

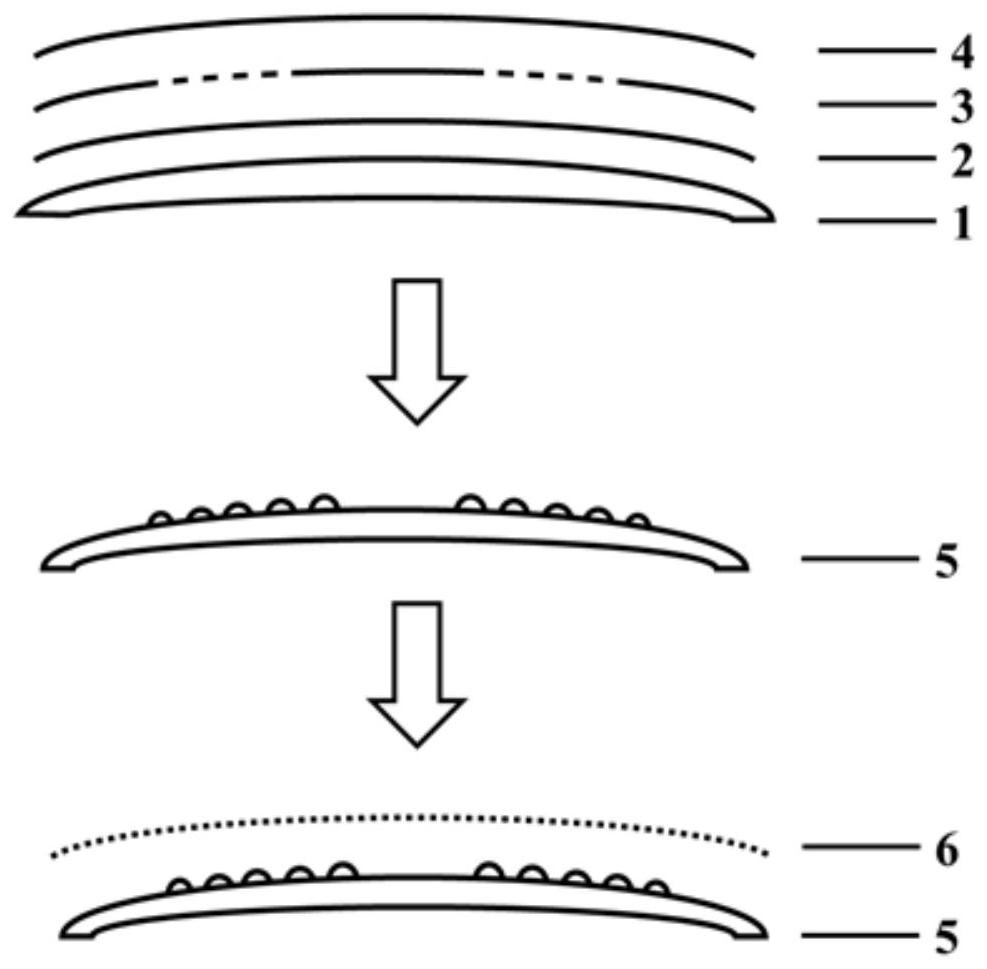

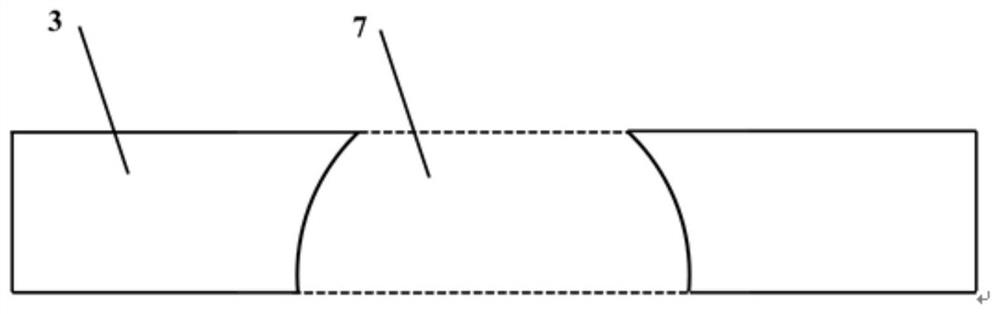

[0021] Such as figure 1 As shown, the present invention comprises a main lens 1, a hardening layer 2, a metal sheet 3, a multilayer film 4 and an optical film 6, and the thin film microstructure lens 5 is formed by a combination of high and low refractive index materials to form a multilayer film, and its refractive index is the same as that of the main lens. 1 The refractive index is close. The thin-film microstructure lens 5 is closely attached to the metal sheet 3 with good plasticity on the hardened main lens 1, and the designed multi-layer film 4 with a refractive index close to the main lens 1 is coated on the lens covering the metal sheet 3 , wherein the refractive index difference between the multilayer film 4 and the main lens 1 is between ±0.1. A plurality of circular holes 7 are distributed on the metal sheet 3, the thickness of the metal sheet 3 is between 10-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com