Continuous paint scraping production line

A production line and enameled wire technology, applied in conductor/cable supply devices, electrical components, circuits, etc., to reduce manual labor, prevent damage, and improve the effect of paint scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

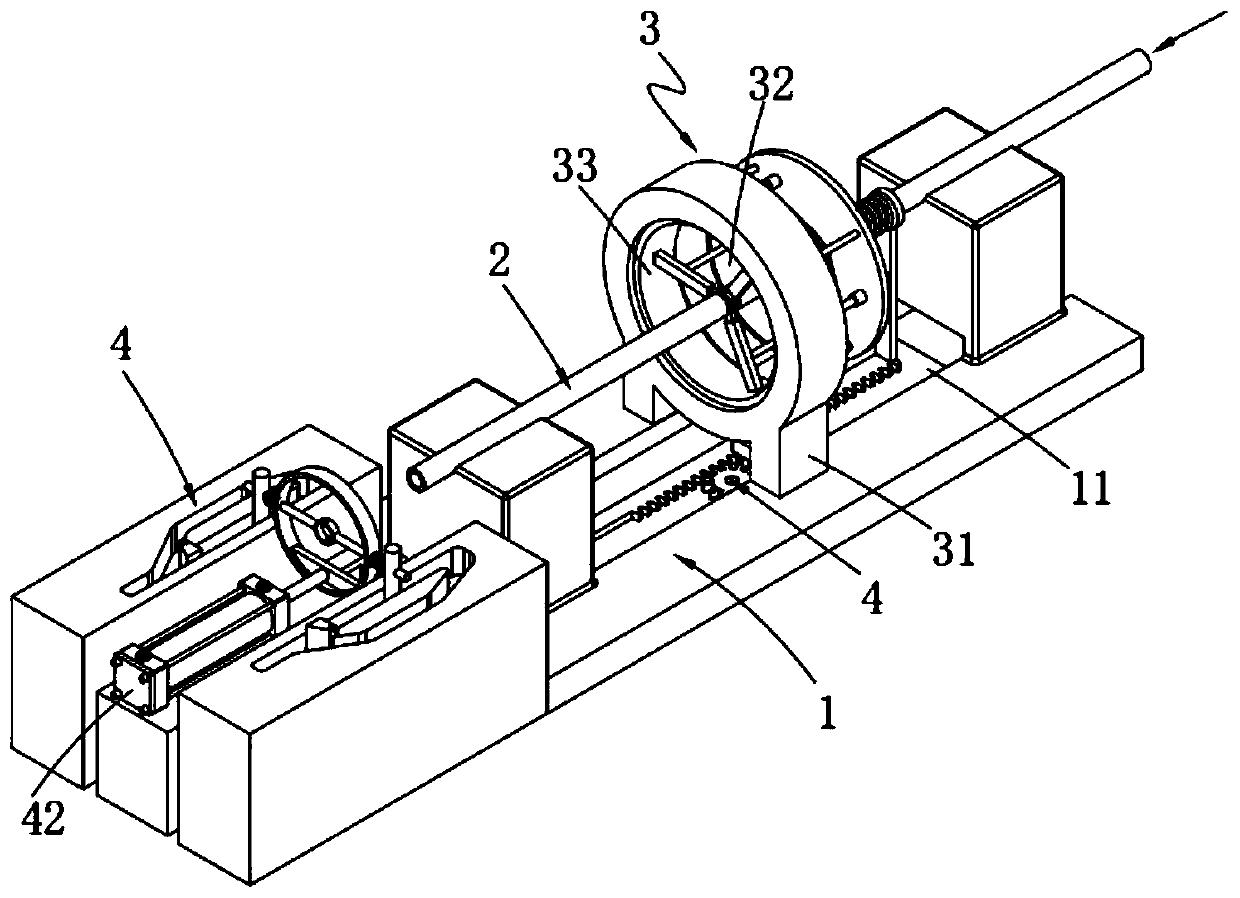

[0058] Such as figure 1 As shown, a continuous paint scraping production line includes a first base 1 and a conveying pipe 2, the middle of the first base 1 is provided with a first groove 11 along its length, and the conveying pipe 2 runs along the first The length direction of the base 1 is set on the first base 1, and the middle part of the conveying pipeline 2 is provided with a gap 21, which also includes:

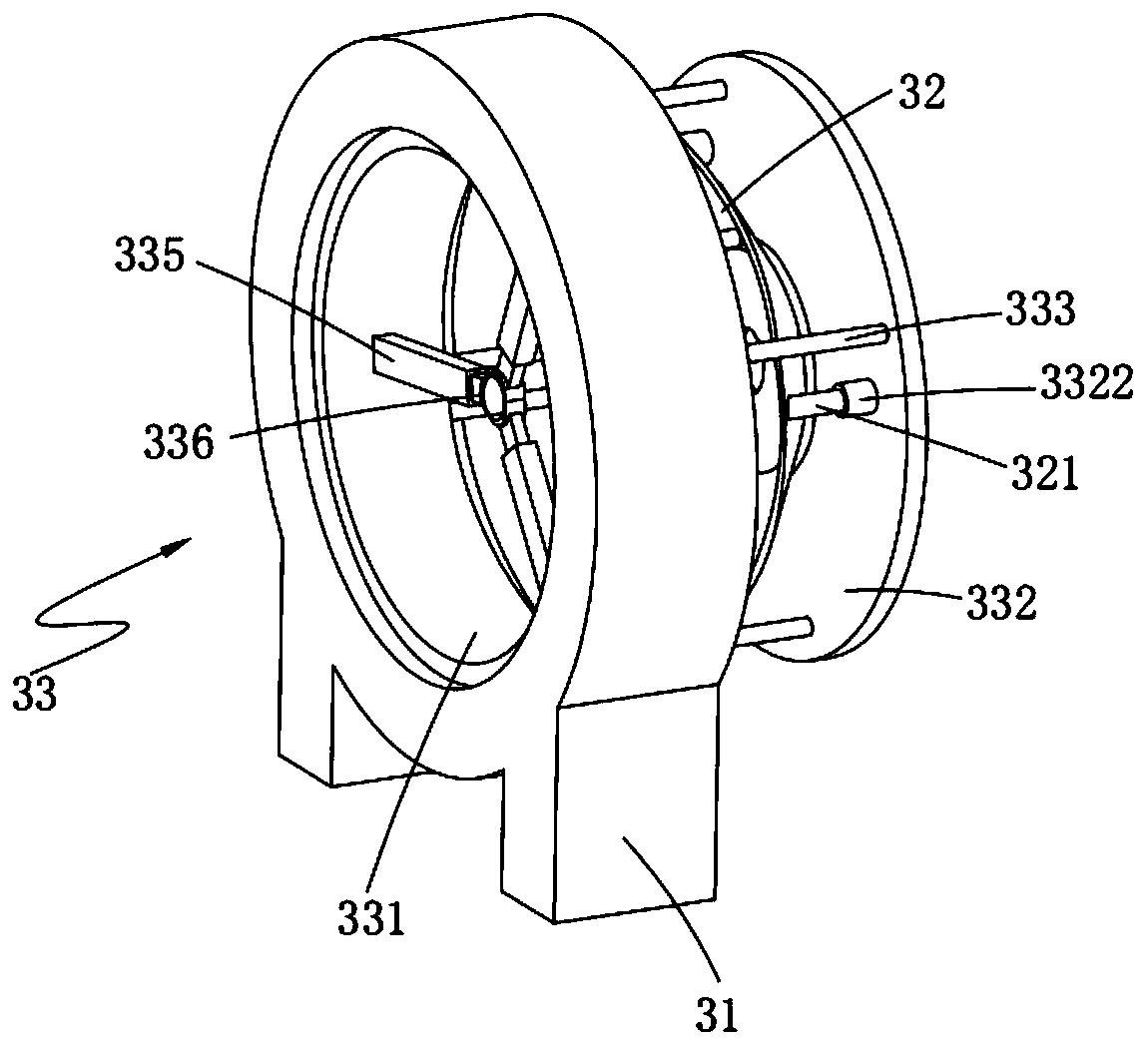

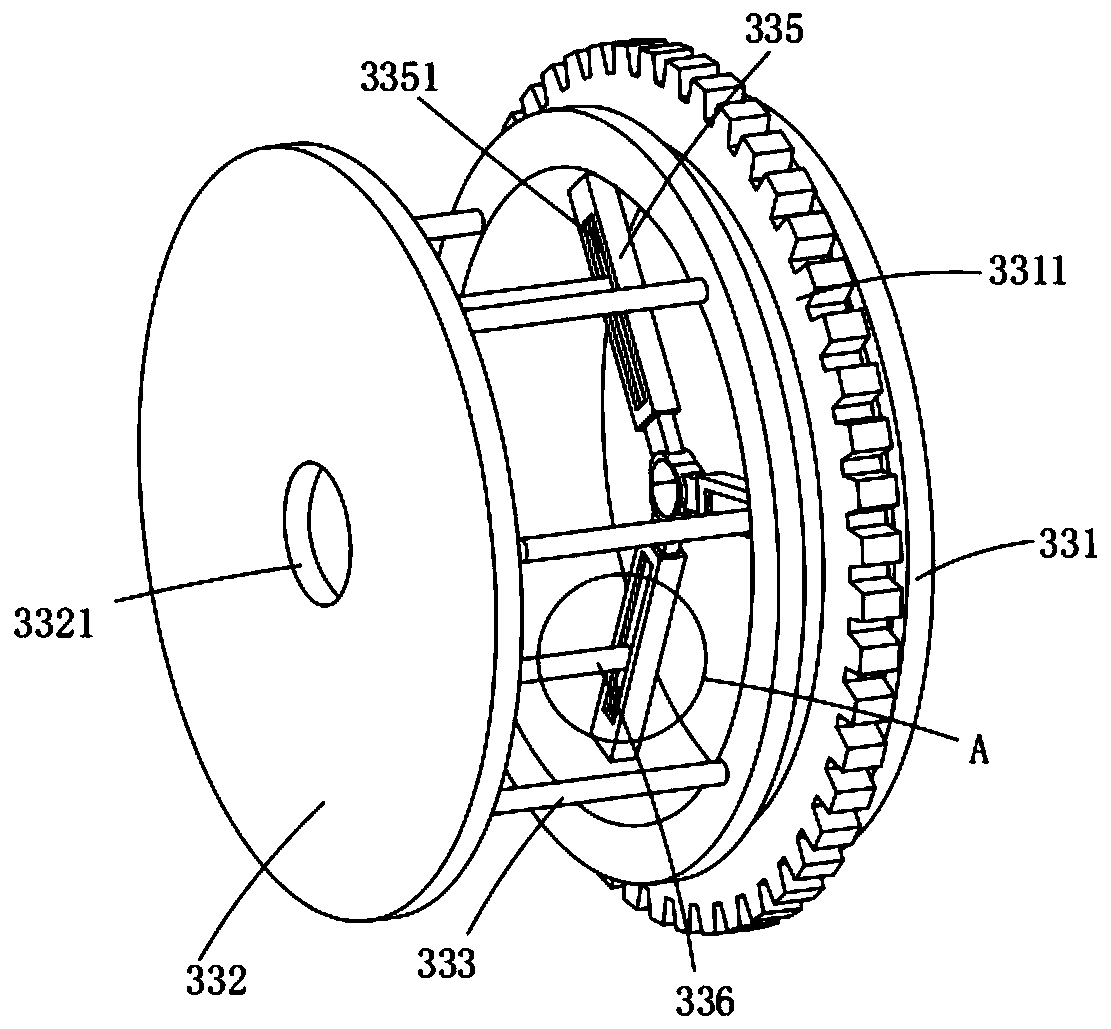

[0059] The scraping mechanism 3, the scraping mechanism 3 includes a second base 31, a scraping assembly 33 and a first resistance member 32, the second base 31 is arranged on the first base 1, the scraping assembly 33 Rotatingly arranged in the second base 31, the first resisting member 32 is elastically connected to the scraper assembly 33, which is sleeved outside the delivery pipeline 2, and along the length of the delivery pipeline 2 Orientation swipeable settings; and

[0060] The traction mechanism 4, the traction mechanism 4 is arranged at one end of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com