Titanium niobium oxide/vertical graphene/titanium carbide-carbon composite material and its preparation method and application

A technology of carbon composite materials and titanium carbide, which is applied in the direction of electrochemical generators, active material electrodes, structural parts, etc., can solve the problems of low safety performance and achieve the effect of improving structural stability, high energy density, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0030] Preparation example (vertical graphene / titanium carbide-carbon material)

[0031] (1) Ultrasonic the Ti6Al4V base material with dilute hydrochloric acid, and then wash it several times with deionized water and ethanol to remove the oil on the surface.

[0032] (2) Put the Ti6Al4V base material obtained in step (1) in a tube furnace, and raise the temperature to 800° C. under the atmosphere of argon and hydrogen. Then introduce the carbon-containing liquid into the cavity by bubbling, keep it warm for 1.5 hours, and get the titanium carbide-carbon material grown on the Ti6Al4V substrate after taking it out;

[0033] (3) The titanium carbide-carbon material obtained in step (2) was placed in a tube furnace, and vacuumed to make the system pressure reach 10 mTorr. Then the temperature was raised to 500°C, and hydrogen plasma was generated when the microwave power reached 600W under the hydrogen atmosphere. After the titanium carbide-carbon is treated with plasma, the tem...

Embodiment 1

[0035] Weigh 0.2849g C 12 h 28 o 4 Ti, add 60mL absolute ethanol, stir for 10 minutes, then add 1.35g NbCl 5, and stirred for 15 minutes until completely dissolved to form a mixed solution. Put the VG@TiC / C base material into the mixed solution and then move it into a polytetrafluoroethylene autoclave, seal the autoclave, and conduct a hydrothermal reaction at 200°C for 24 hours. After the reaction, cool to room temperature 25°C, pour out the solution and take out the sample, wash and dry it with deionized water, then cool naturally to room temperature 25°C to obtain Ti 2 Nb 10 o 29 Precursor. Finally, it was put into a tube furnace and sintered at 700°C for 2 hours with argon gas to obtain Ti 2 Nb 10 o 29 @VG@TiC-C target product.

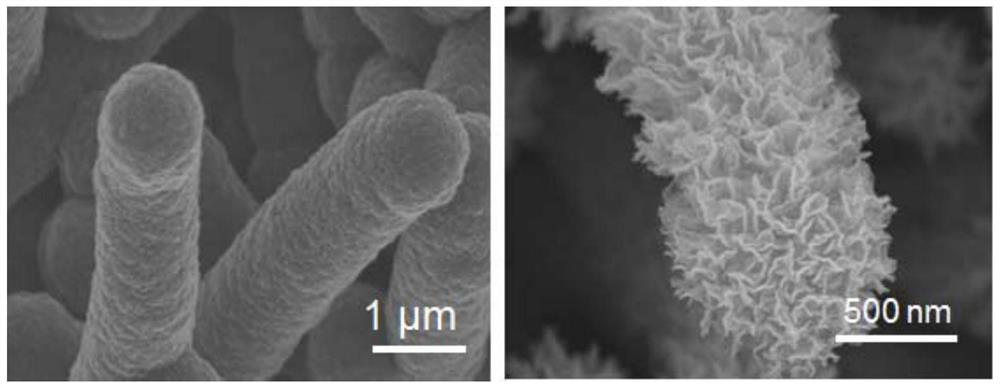

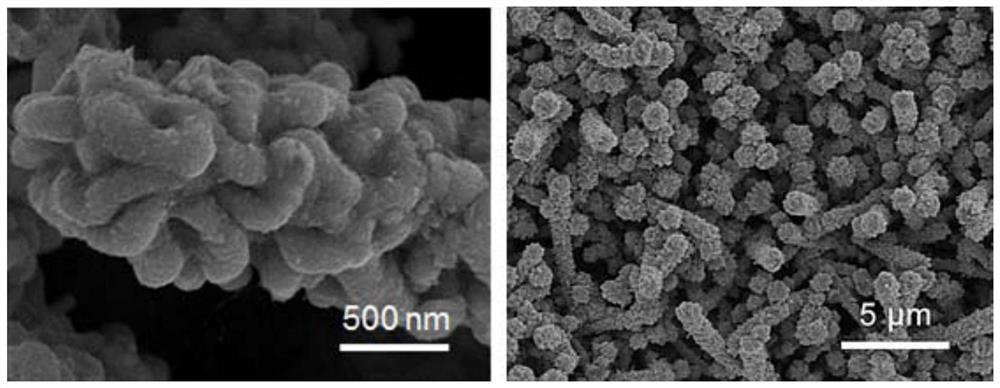

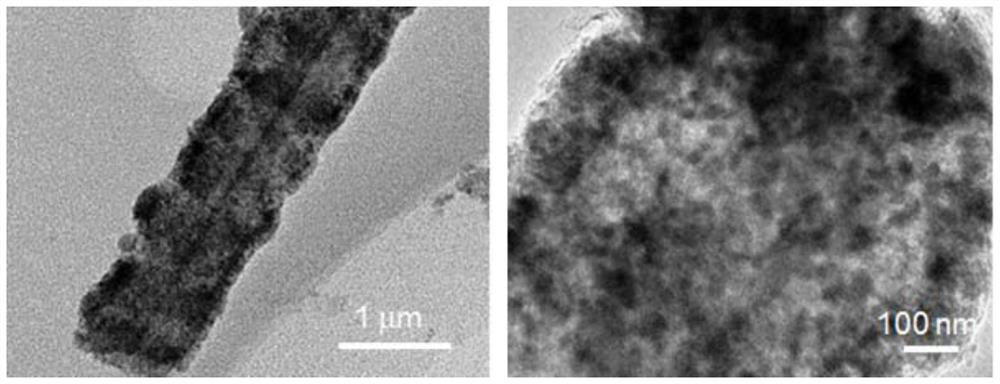

[0036] The scanning electron microscope images of TiC-C and VG@TiC / C prepared in Example 1 are as follows figure 1 Shown; Ti obtained in embodiment 1 2 Nb 10 o 29 The scanning electron microscope image of @VG@TiC / C is as follows fi...

Embodiment 2

[0038] Weigh 0.2849g C 12 h 28 o 4 Ti, add 60mL absolute ethanol, stir for 10 minutes, then add 1.35g NbCl 5 , and stirred for 15 minutes until completely dissolved to form a mixed solution. Put the VG@TiC / C base material into the mixed solution and then move it into a polytetrafluoroethylene autoclave, seal the autoclave, and conduct a hydrothermal reaction at 180°C for 10 hours. After the reaction, cool to room temperature 25°C, pour out the solution and take out the sample, wash and dry it with deionized water, then cool naturally to room temperature 25°C to obtain Ti 2 Nb 10 o 29 Precursor. Finally, it was put into a tube furnace and sintered at 750°C for 2 hours with argon gas to obtain Ti 2 Nb 10 o 29 @VG@TiC-C target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com