A disc rotary brick press

A rotary, brick press technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of low production efficiency and time-consuming, and achieve the effect of improving production efficiency, reducing labor costs, and ensuring density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

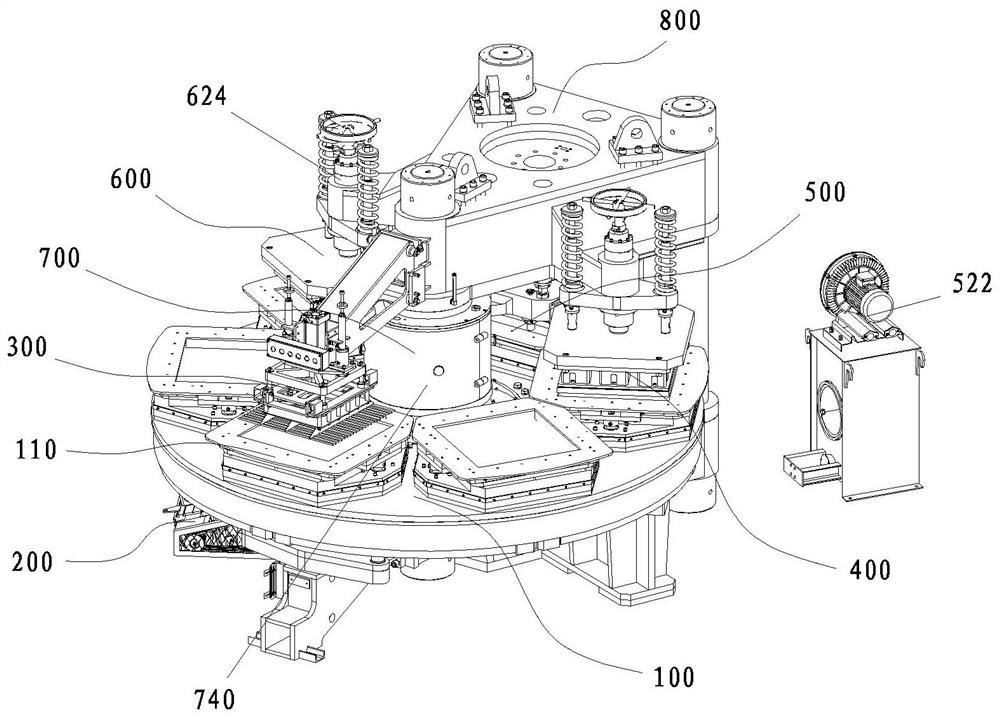

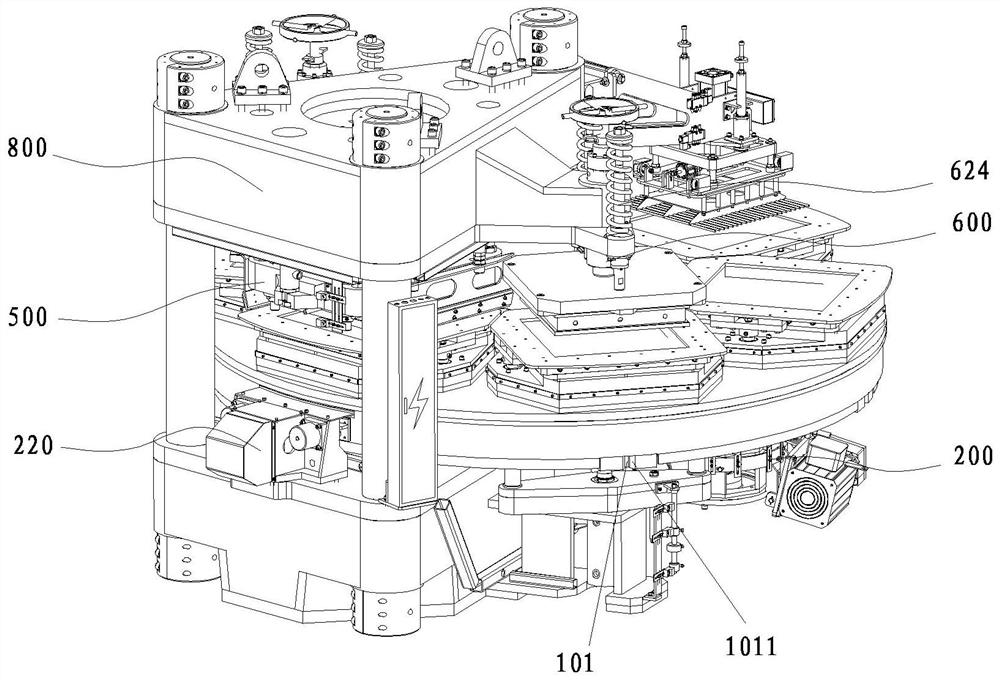

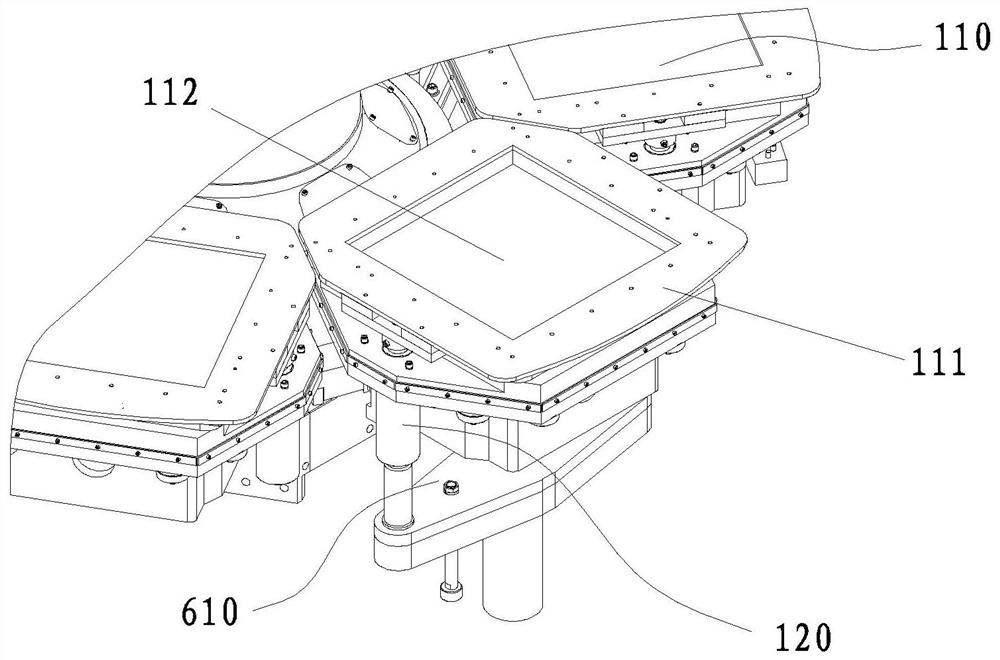

[0052] Such as Figure 1-32As shown, a disc rotary brick press includes a turntable 100, and a plurality of molds 110 arranged on the turntable. The molds 110 are arranged at equal intervals along the circumference of the turntable. In this embodiment, the molds The number of 110 is six; among them: it also includes a controller (not shown in the figure), a rotating drive mechanism 200 for driving the turntable 100, a spreading mechanism 300 for spreading the raw materials, and a pre-pressing mechanism for pre-pressing the raw materials. Mechanism 400, main pressing mechanism 500 for main pressing raw materials, demoulding mechanism 600 for demoulding formed bricks, main shaft mechanism 700 at the center of turntable 100, load spreading mechanism 300, pre-pressing mechanism 400, main pressing mechanism 500 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com