Transfer robot picking task scheduling method for movable goods shelf warehousing system

A technology for handling robots and task scheduling, applied in transportation, packaging, storage devices, etc., can solve the problems of reducing warehouse picking efficiency, taking all shelves into account, and lengthening driving distance, so as to improve picking efficiency, save driving distance and Time, the effect of reducing walking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

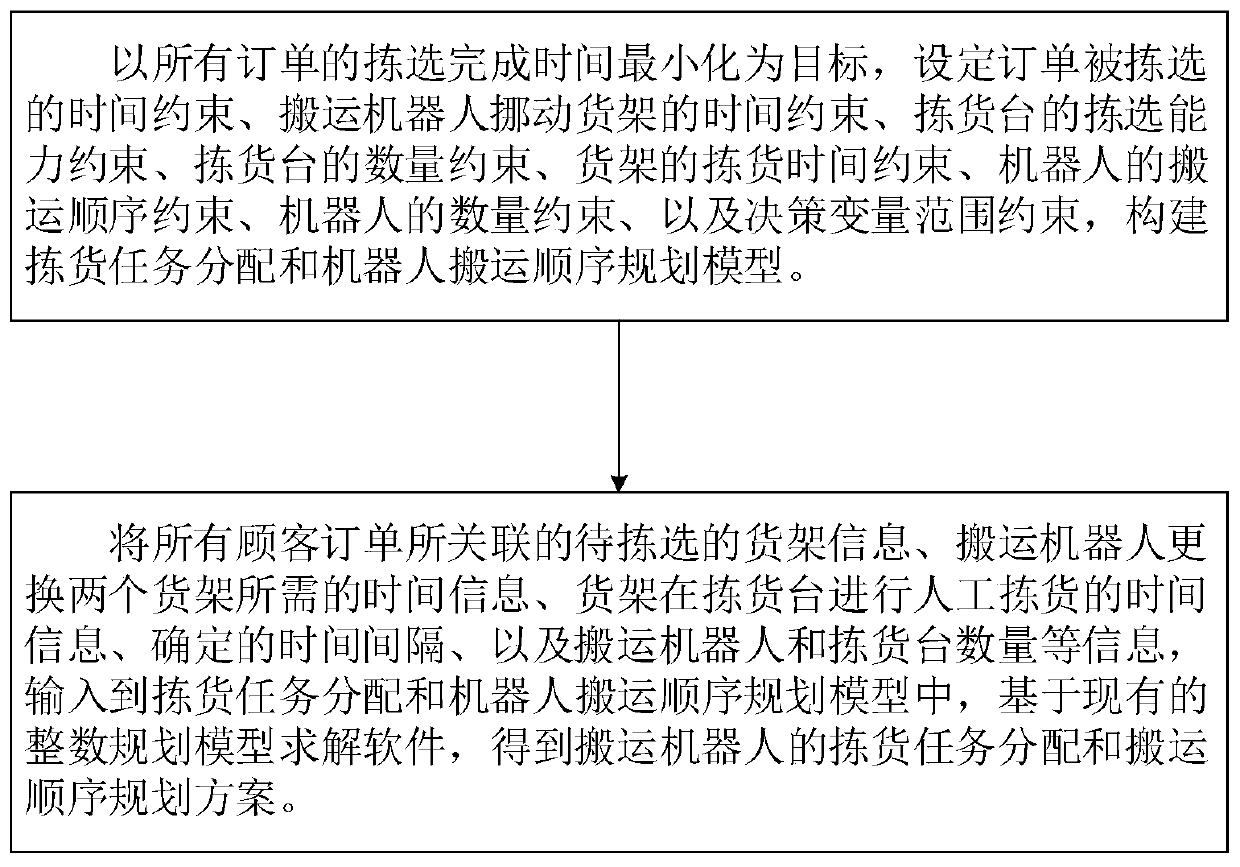

[0056] Through the analysis of the characteristics of the handling robot and the mobile shelf storage system, the present invention distributes the shelves to be transported to all the handling robots for all customer orders and their associated shelf collections to be picked, and plans the handling sequence of the robots; When planning the handling sequence of the robot, let the robot move the loaded shelf to the position of the next shelf to be transported when it leaves the picking platform. The shelf is put down; in this way, the walking distance of the handling robot can be reduced, and the picking efficiency of the system can be improved; by establishing a mathematical model to solve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com