A yarn shoelace segment dyeing device and a method of using the same

A technology for shoelaces and yarns, which is applied to the removal of liquid/gas/steam by suction, equipment configuration for processing textile materials, textiles and papermaking, etc. It can solve the problems affecting the dyeing work, shoelaces, and yarn shoelaces. Miscellaneous spots and other problems can be improved to improve the efficiency of section dyeing, reduce the processing flow and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

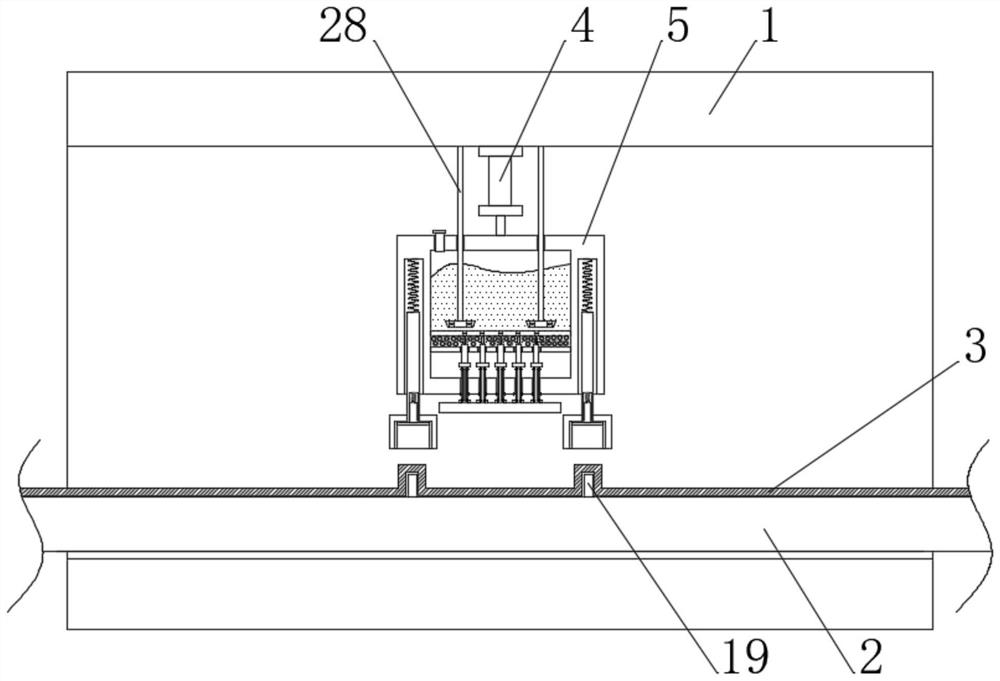

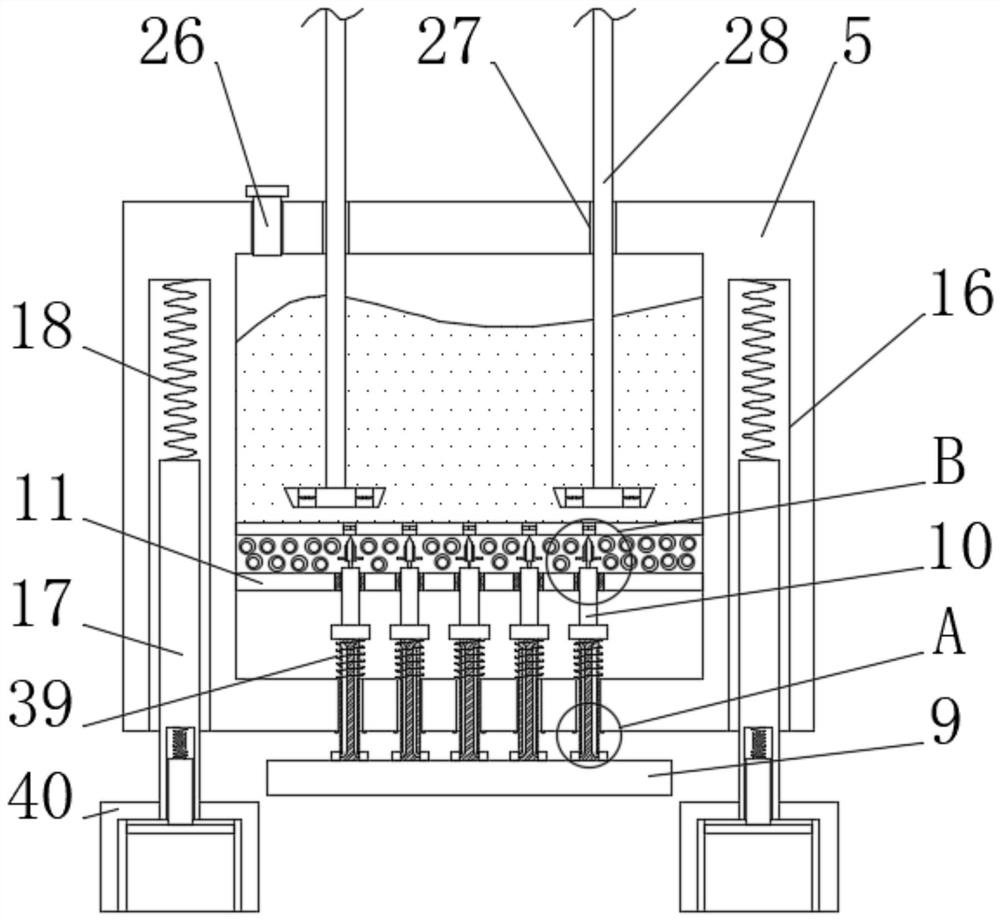

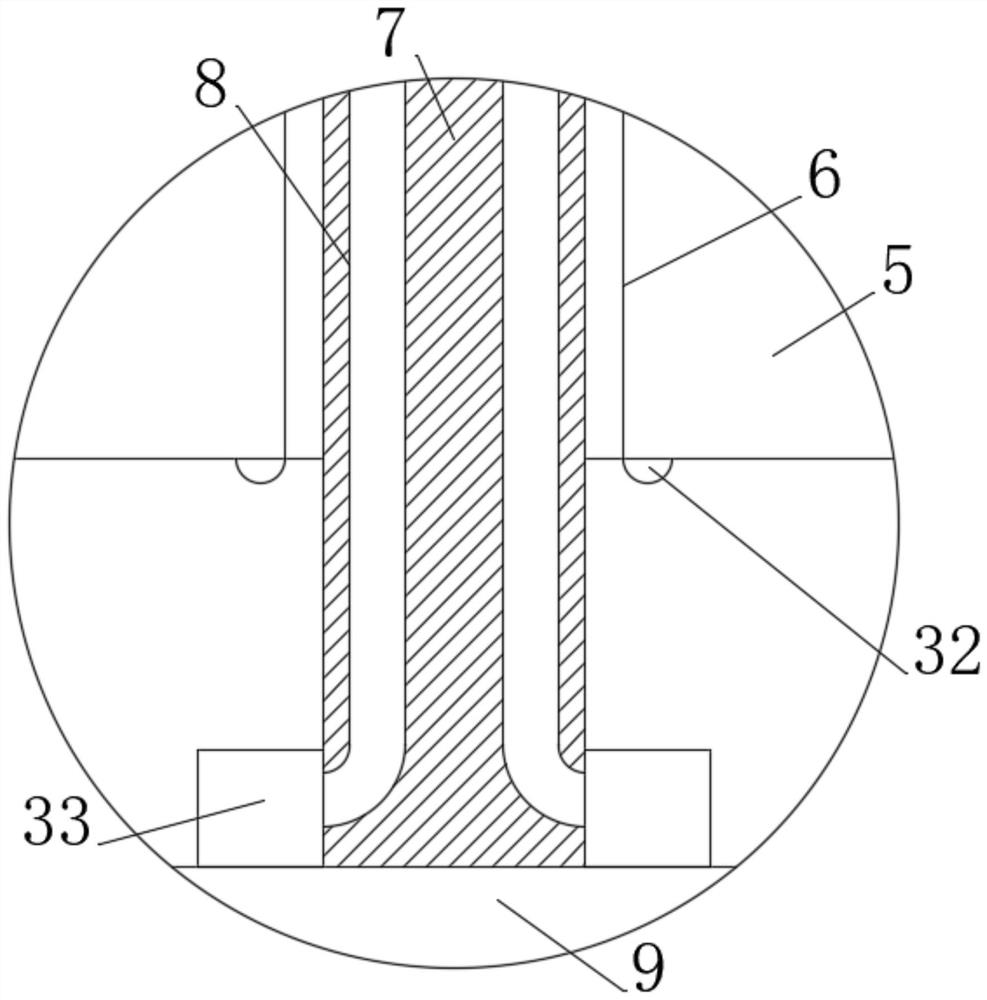

[0038] see Figure 1-4 , a yarn shoelace segment dyeing device, comprising a segment dyeing device main body 1, a transmission device 2 is installed in the main body 1 of the segment dyeing device, a yarn shoelace 3 is arranged on the upper end of the transmission device 2, and the upper inner wall of the main body 1 of the segment dyeing device is provided. A cylinder 4 is fixedly connected, the output end of the cylinder 4 is fixedly connected with a dye box 5, a plurality of first through holes 6 evenly distributed are drilled at the inner bottom end of the dye box 5, and a first sliding rod 7 is inserted in the first through holes 6 , a plurality of evenly distributed first liquid guide holes 8 are drilled inside the first sliding rod 7, a contact plate 9 is fixedly connected to the bottom end of the first sliding rod 7, a connecting rod 10 is fixedly connected to the upper end of the first sliding rod 7, and the connecting rod 10 and the inner bottom end of the dye box 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com