Autonomous removing trolley for moon dust on surface of high-voltage polarized solar cell

A solar cell and high-voltage technology, applied in electrostatic cleaning, cleaning methods using tools, photovoltaic power generation, etc., can solve the problems of large energy consumption, small application range, and low work efficiency, and achieve low energy consumption and high applicability Broad, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

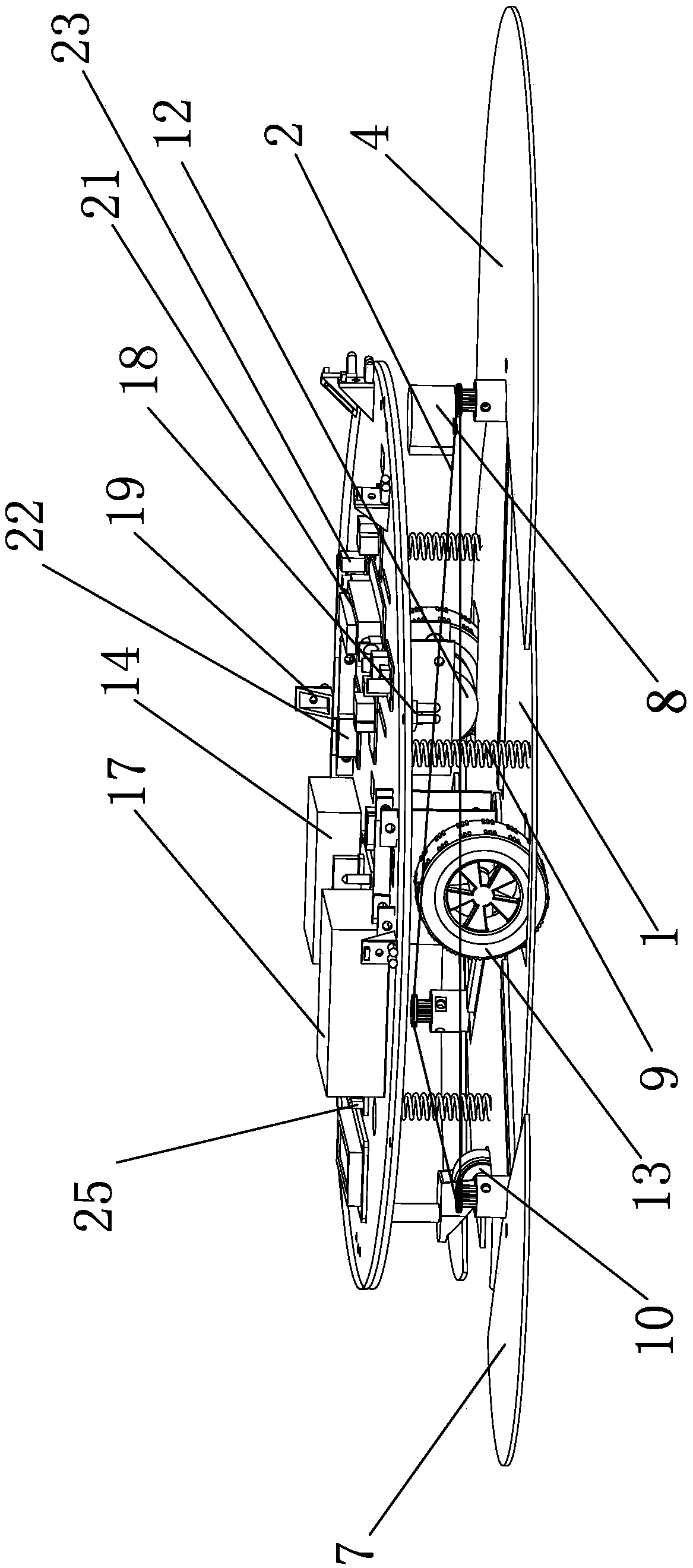

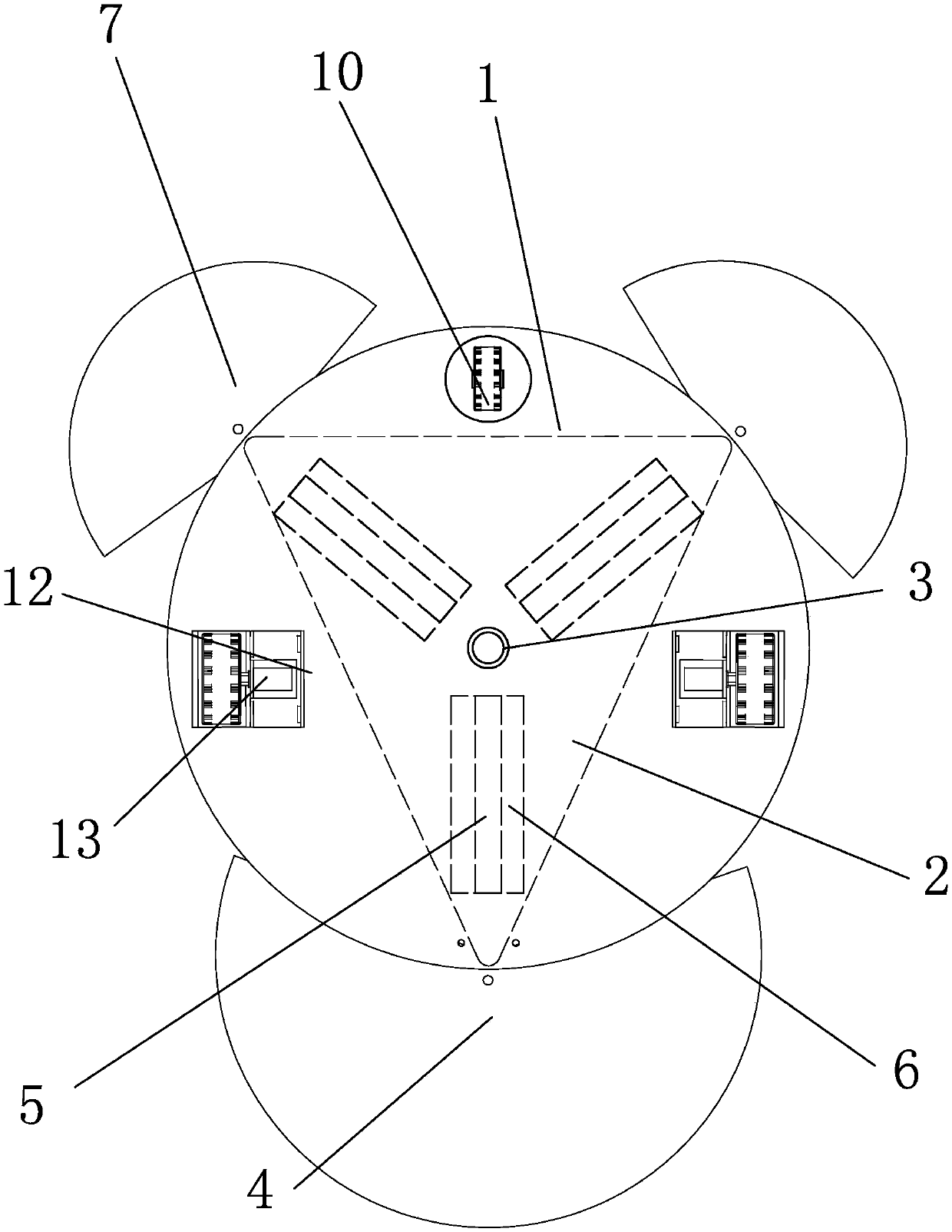

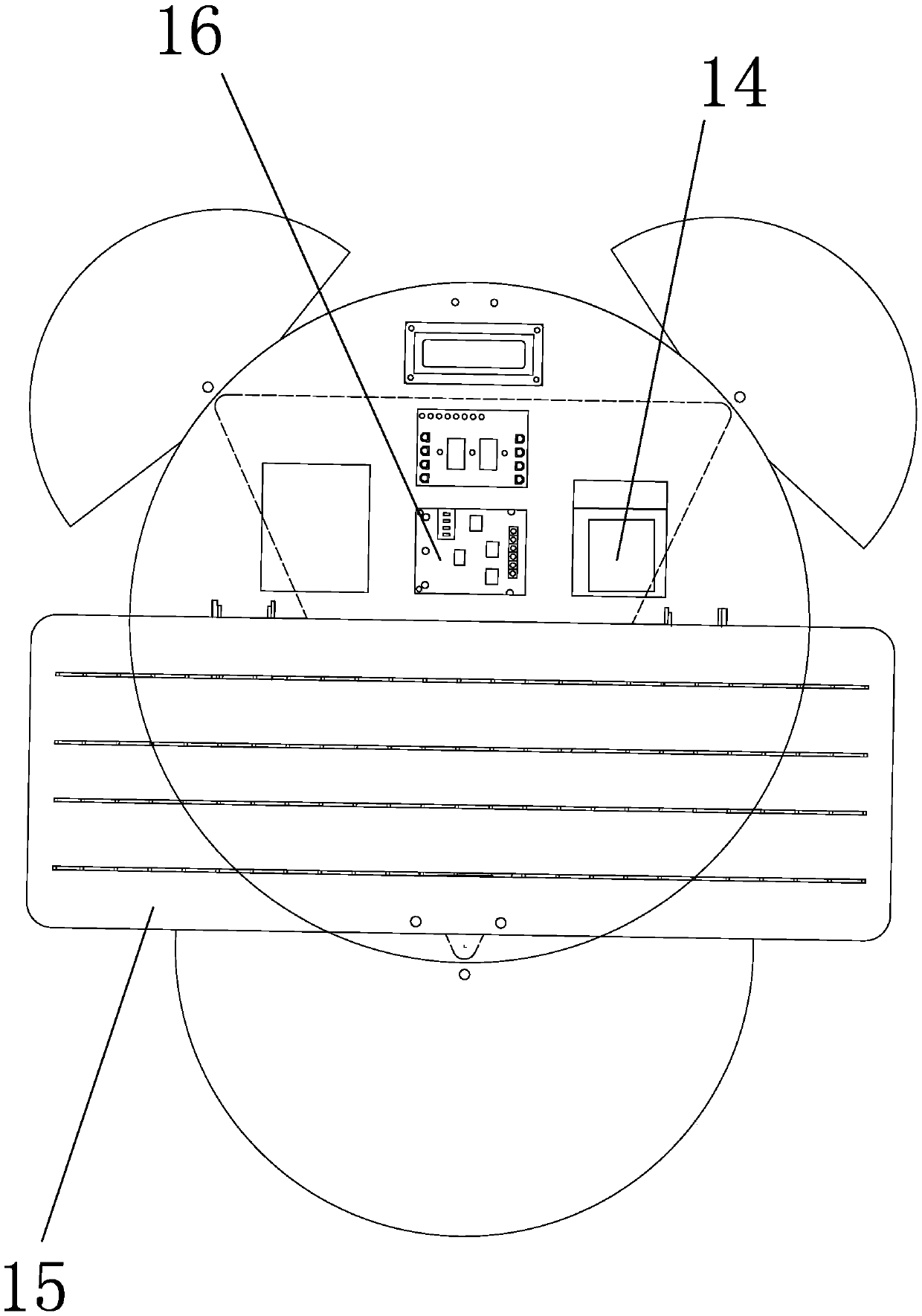

[0026] Specific implementation mode 1: Combination Figure 1 to Figure 5 To illustrate this embodiment, the device described in this embodiment includes a dust removal layer, a drive layer, an energy supply layer and a circular support plate;

[0027] The upper surface of the circular support plate is provided with a cylindrical cavity, the diameter of the bottom surface of the cylindrical cavity is smaller than the diameter of the upper surface of the support plate, and a plurality of cliff avoiding infrared sensors 18 are equidistantly arranged on the lower surface of the support plate along the circumferential direction. At the edge, a plurality of obstacle avoidance infrared sensors 19 are equidistantly arranged at the edge of the upper surface of the support plate along the circumferential direction, and a stepping motor 3 is arranged at the center of the lower surface of the support plate;

[0028] The dust removal layer includes a circular bottom plate 1, a synchronous belt 2...

specific Embodiment approach 2

[0033] Specific implementation manner two: combination Figure 1 to Figure 4 To describe this embodiment, the shape of the dust removal main electrode 4 in this embodiment is a fan shape with a central angle of 180°-270°, and other composition modes are the same as the first embodiment.

specific Embodiment approach 3

[0034] Specific implementation mode three: combination Figure 1 to Figure 4 To illustrate this embodiment, the shape of the auxiliary dust removal electrode 7 in this embodiment is a sector shape with a central angle of 90°-180°, and other composition modes are the same as the first embodiment.

[0035] Three dust removal electrodes are designed, all of which are fan-shaped to ensure the maximum dust removal electrode. The front electrode and the rear electrode should be able to cover the width direction of the whole car to ensure that dust removal is not omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com