Vapor-liquid diverting type capillary core vapor chamber heat exchanger and preparation method

A capillary core and heat exchanger technology, which is applied in heat exchange equipment, indirect heat exchangers, lighting and heating equipment, etc., can solve the mutual interference between steam and condensate, restrict the working performance of capillary core soaking plate, and affect effective distribution. and flow problems, to achieve the effect of reducing mutual influence, strengthening boiling heat transfer, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

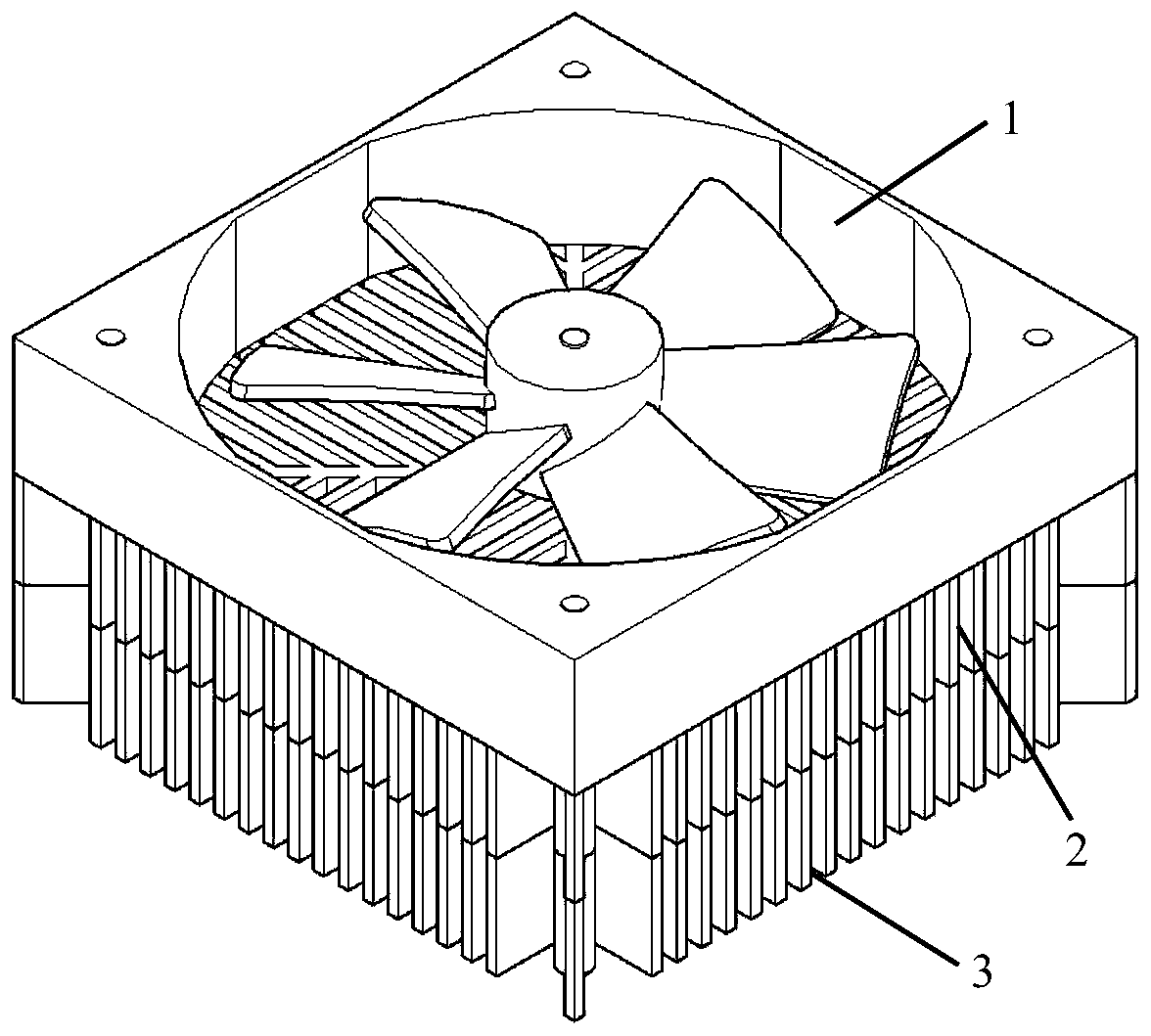

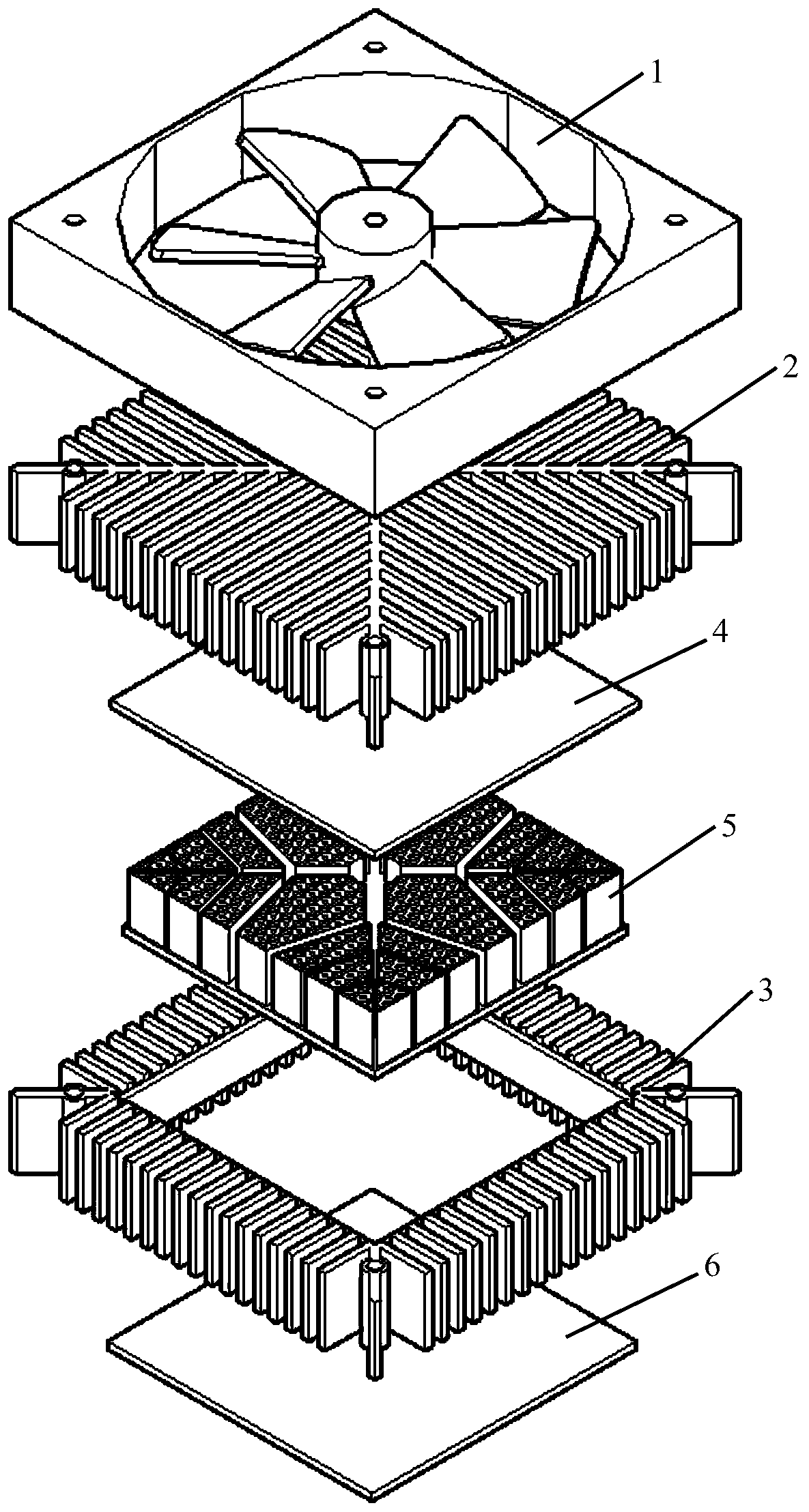

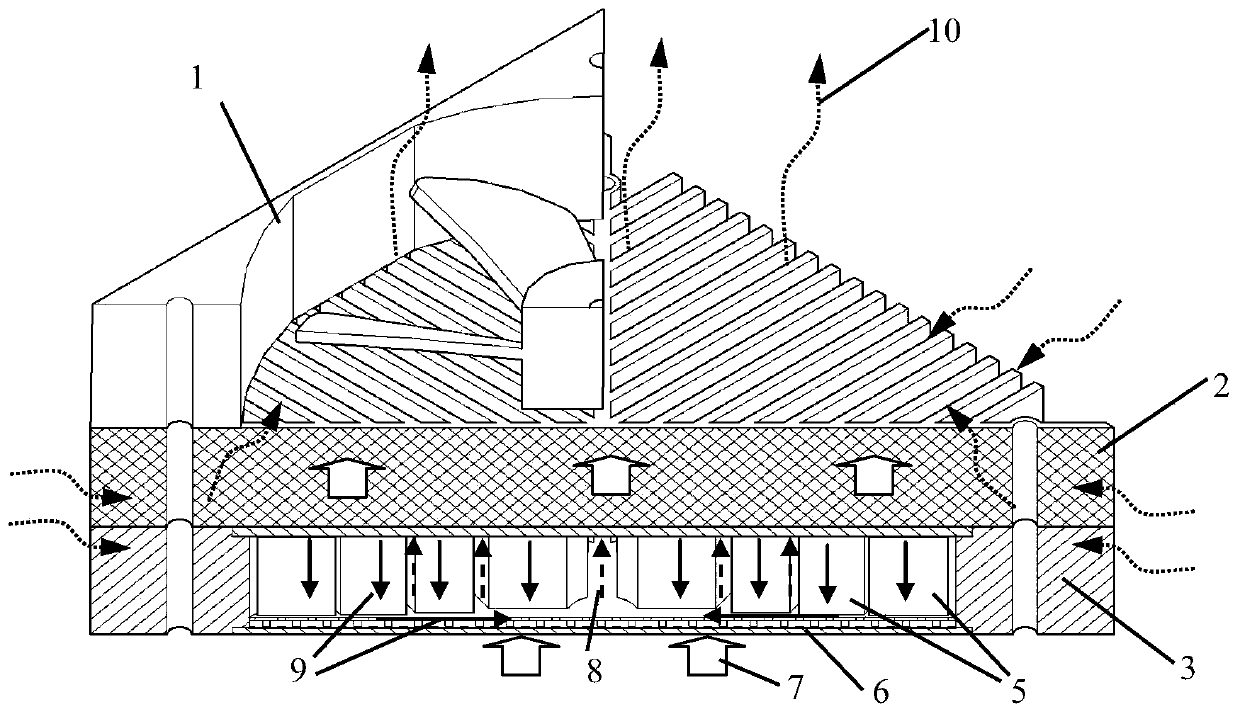

[0032] like Figure 1-2 As shown, a capillary vapor chamber heat exchanger with vapor-liquid separation is composed of a heat dissipation fan 1, a cover plate fin 2, a steam chamber side wall and a side wall rib 3, a steam chamber upper cover plate 4, and a steam chamber capillary core 5 and the lower cover plate 6 of the steam chamber. In order to ensure the good working performance of the radiator, the steam chamber shell and fins can be made of metal materials with good thermal conductivity, especially in order to reduce the weight of the radiator. Processing of aluminum alloy materials with high coefficient. The steam chamber is filled with sintered capillary cores, and steam channels are processed in the capillary cores. The steam chamber is filled with liquid working fluids such as water, acetone, alcohol, ammonia, and refrigerant that undergo phase change when heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com