Rocker arm checking fixture and checking method

A technology of checking tool and rear rocker arm, applied in the automotive field, can solve the problems of increasing difficulty, shape and size, many matching dimensions, and inaccurate dimensions, so as to improve product qualification rate, facilitate assembly and disassembly, and ensure consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

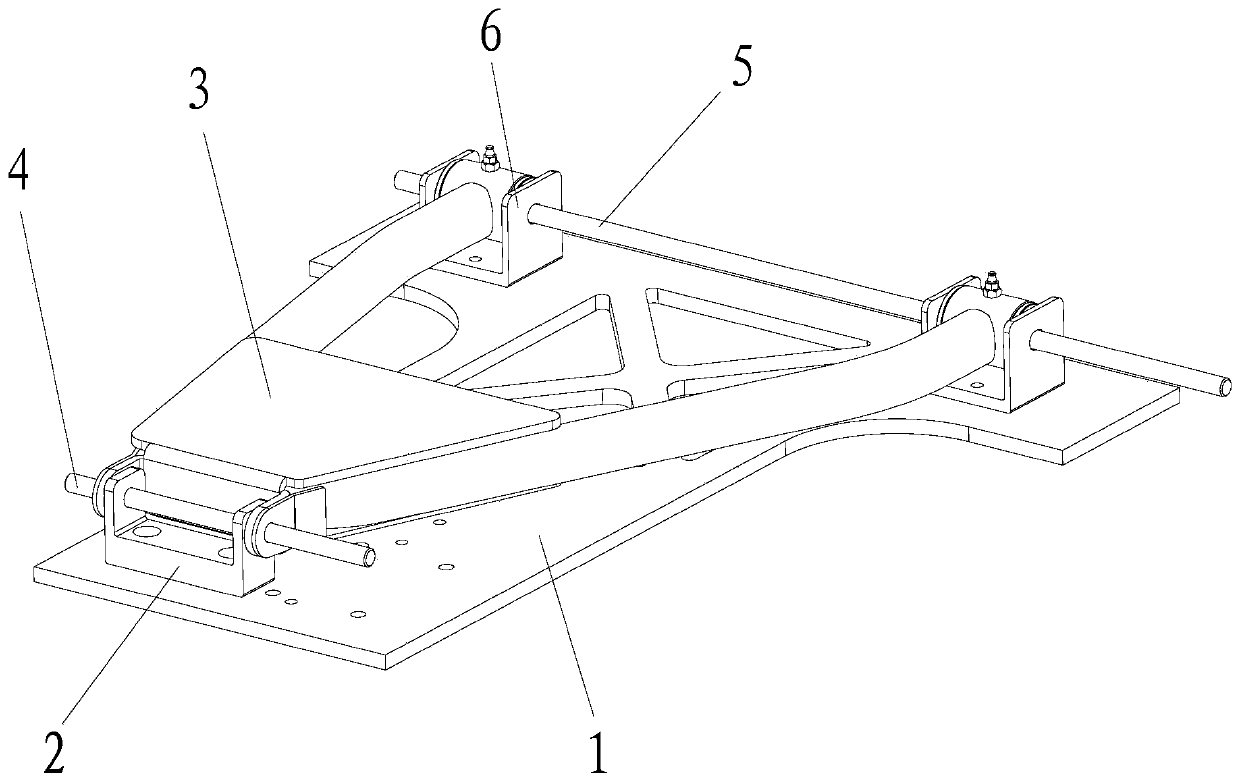

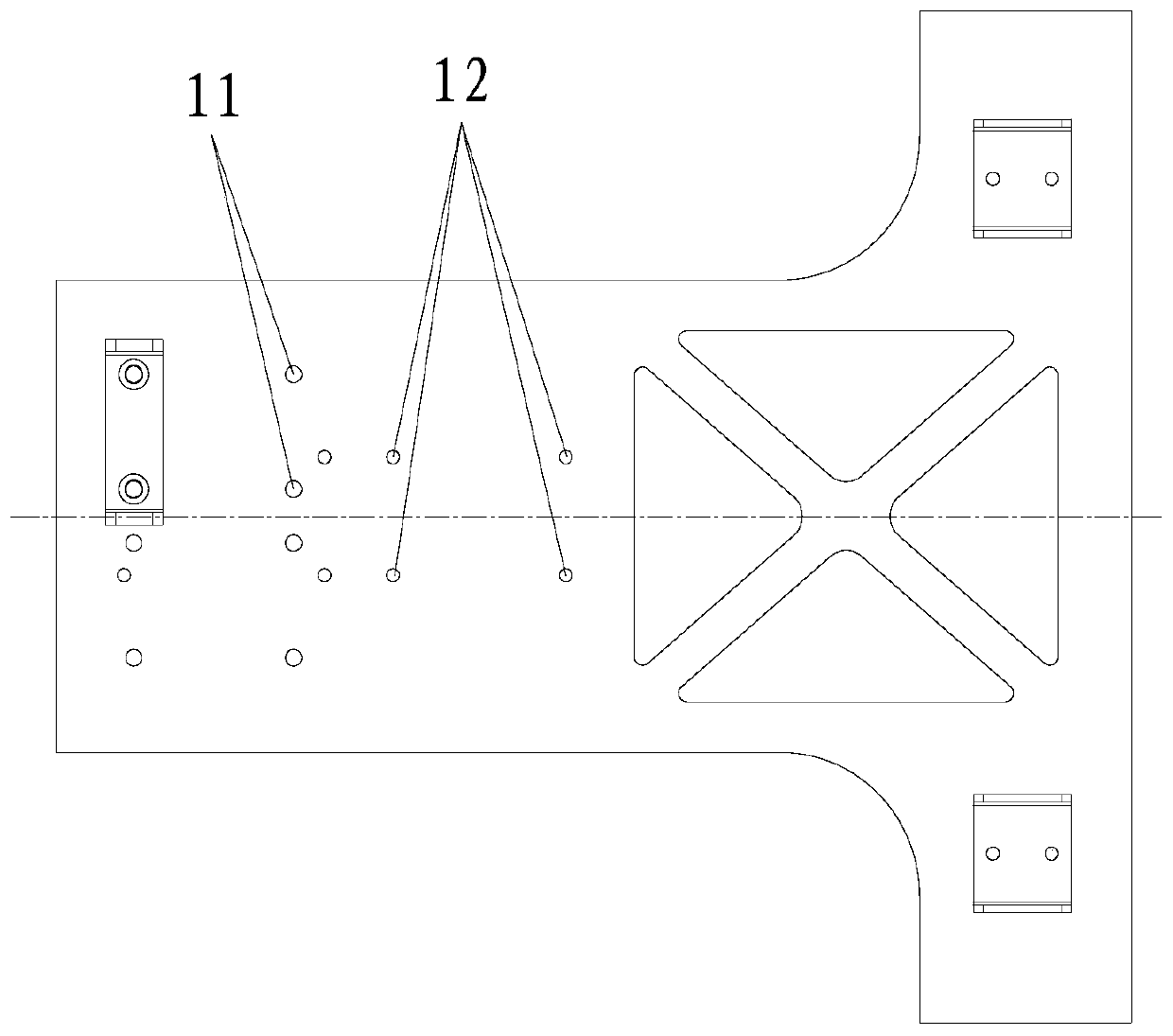

[0058] Please refer to Figure 1-Figure 4 , a rocker arm inspection tool, including a base plate 1, a tailstock 2, a first connecting portion 4 for positioning one end of the rear rocker arm assembly 3, and a second connecting portion 5 for positioning the other end of the rear rocker arm assembly 3 and a plurality of end tube sockets 6;

[0059] The tailstock 2 is mounted on one end of the bottom plate 1;

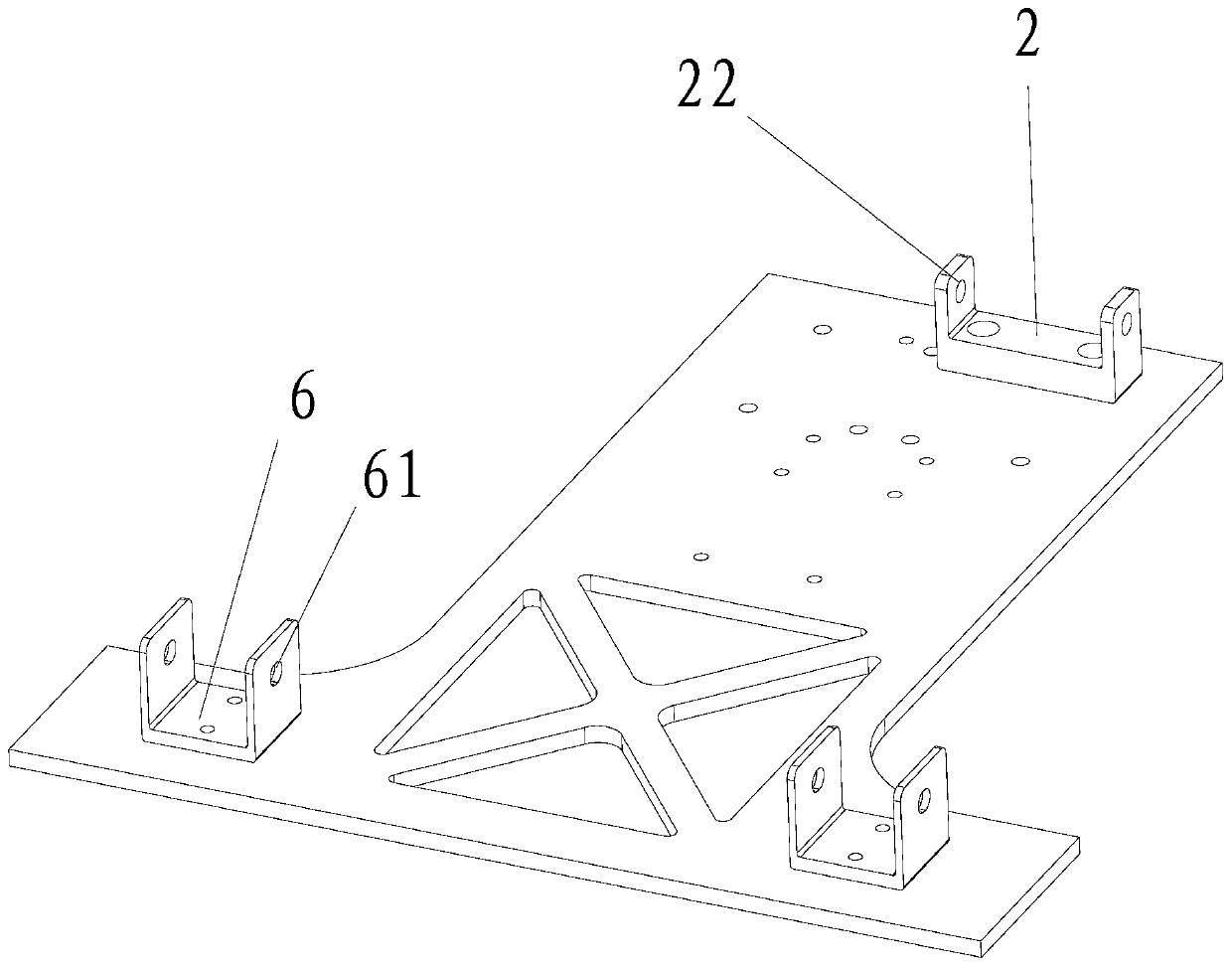

[0060] A plurality of end sockets 6 are arranged symmetrically and installed on the end of the bottom plate 1 away from the tailstock 2;

[0061] The first connecting part 4 is inserted on the tailstock 2;

[0062] The second connecting part 5 is sequentially inserted on the plurality of end sockets 6 and the vertical horizontal planes of the second connecting part 5 and the first connecting part 4 are parallel to each other.

[0063] Preferably, there are two end pipe seats 6;

[0064] Specifically, the two end pipe seats 6 are installed on the bottom plate 1 in a sym...

Embodiment 2

[0080] The difference between this embodiment and the first embodiment is that another structure of the tailstock and the first connecting part is defined.

[0081] refer to Figure 5-Figure 8 , the top of the tailstock 2 is an inclined surface 21, the inclined surface 21 faces the side where the end pipe seat 6 is located and is gradually inclined outwardly from bottom to top;

[0082] The inclined surface 21 is provided with four third through-holes 211 which are distributed axially symmetrically;

[0083] Specifically, the bottom of the tailstock 2 is connected to the corresponding second bolt hole by bolts; each third through hole 211 is correspondingly inserted with a first connecting part 4, and the first connecting part 4 vertically passes through the rear rocker to be tested. One end of the arm assembly 3 is used to fix one end of the rear rocker arm assembly 3, and the lower end of the first connecting part 4 should be pressed against the bottom plate 1;

[0084] Wh...

Embodiment 3

[0086] An inspection method applied to the rocker inspection tool described in Embodiment 1 or Embodiment 2, comprising the following steps:

[0087] S1: installing the tailstock 2 and the end pipe seat 6 at corresponding positions on the bottom plate 1;

[0088] S2: install one end of the rear rocker arm assembly 3 to be inspected on the tailstock 2;

[0089] S3: inserting the first connecting part 4 horizontally and sequentially through the tail stock 2 and the one end of the rear rocker arm assembly 3 to be tested;

[0090] S4: install the other end of the rear rocker arm assembly 3 to be inspected on the corresponding end pipe seat 6;

[0091] S5: When the second connecting portion 5 can pass through the plurality of end pipe seats 6 and the other end of the rear rocker arm assembly 3 to be inspected sequentially, the rear rocker arm assembly 3 is considered qualified, Otherwise, the rear rocker arm assembly 3 is regarded as unqualified.

[0092] To sum up, the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com