A display substrate and its preparation method and display panel

A display substrate, non-display technology, applied in the direction of identification devices, instruments, etc., can solve problems such as poor display screens, achieve borderless display, improve quality, and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

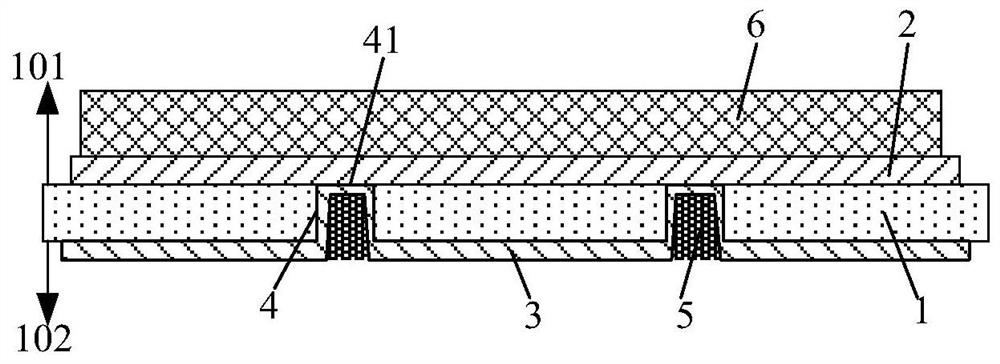

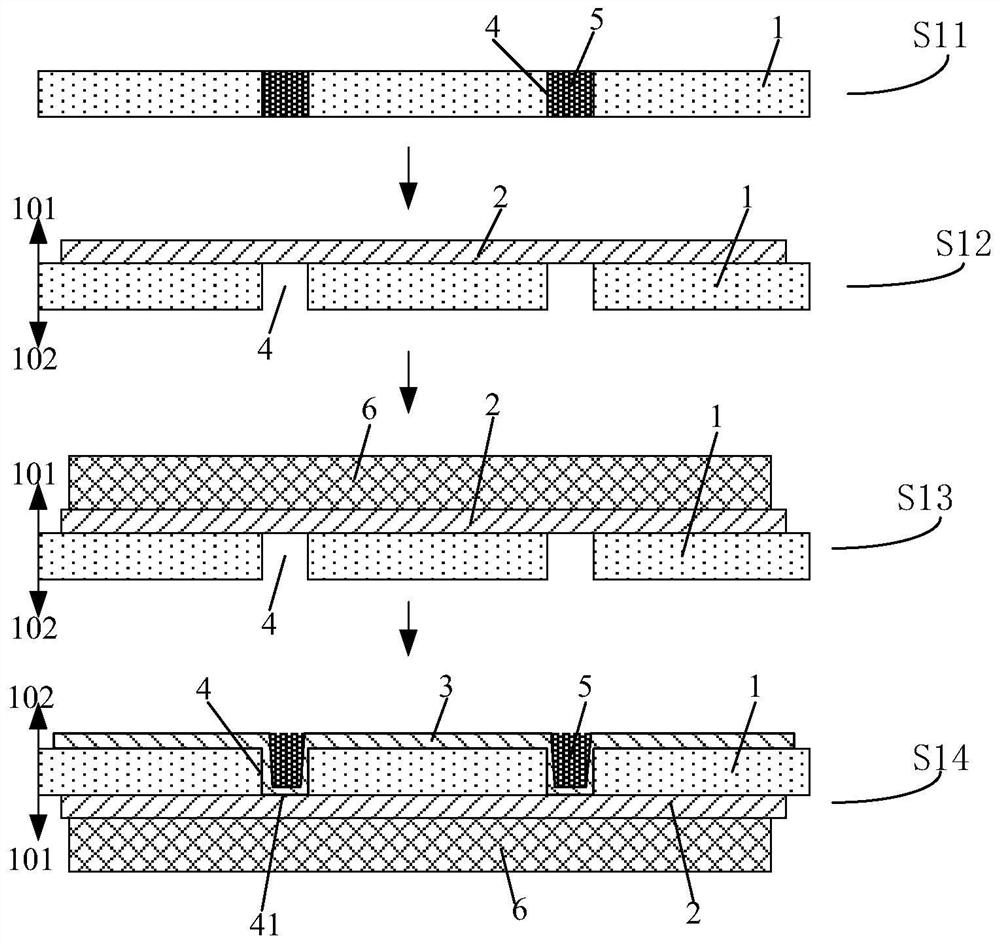

[0039] This embodiment provides a display substrate, such as figure 1 As shown, a substrate 1 is included, and the substrate 1 includes a display side 101 and a non-display side 102 arranged oppositely, and also includes a driving circuit arranged on the display side 101 of the substrate 1 and a binding circuit arranged on the non-display side 102 of the substrate 1, The driving circuit includes a first conductive layer 2 in contact with the substrate 1, the bonding circuit includes a second conductive layer 3 in contact with the substrate 1, a through hole 4 is opened in the substrate 1 through its thickness, and the second conductive layer 3 penetrates The through hole 4 is connected to the first conductive layer 2 ; the through hole 4 is also filled with a resin layer 5 .

[0040] Wherein, the substrate 1 may be a glass substrate or a flexible substrate.

[0041] By making the second conductive layer 3 connect to the first conductive layer 2 through the through hole 4, and...

Embodiment 2

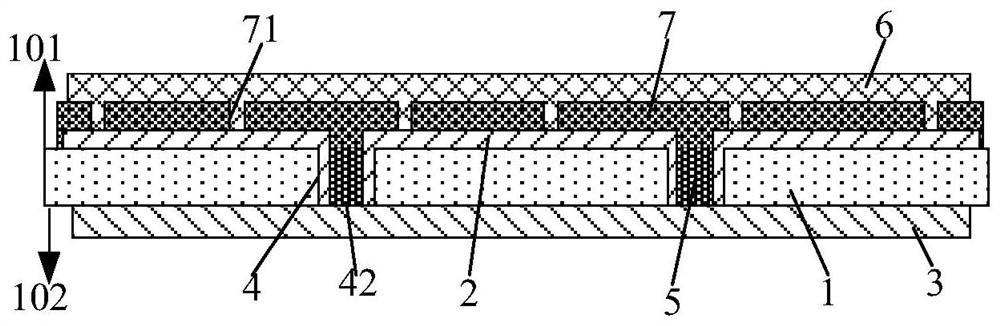

[0055] This embodiment provides a display substrate, which is different from Embodiment 1 in that image 3 As shown, the first conductive layer 2 is connected to the second conductive layer 3 through the via hole 4 .

[0056] In this embodiment, the first conductive layer 2 covers the sidewall of the through hole 4 and extends to the second end opening 42 of the through hole 4; the second end opening 42 is an end of the through hole 4 close to the second conductive layer 3 Opening; the drive circuit also includes a gas conduction layer 7 and a first circuit layer 6, the gas conduction layer 7 and the first circuit layer 6 are arranged on the side of the first conductive layer 2 away from the substrate 1, and the gas conduction layer 7 and the first The circuit layer 6 is arranged away from the substrate 1 in turn; a via hole 71 is opened in the gas conduction layer 7 , and the first conductive layer 2 is connected to the conductive film layer in the first circuit layer 6 throu...

Embodiment 3

[0074] This embodiment provides a display panel, including the display substrate in any one of the above embodiments.

[0075] By using the display substrate in any one of the above-mentioned embodiments, the display panel can not only realize borderless display, but also improve the quality of the display panel.

[0076] The display panel provided by the present invention can be any product or component with display function such as LCD panel, LCD TV, OLED panel, OLED TV, LED panel, LED TV, monitor, mobile phone, and navigator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com