Multi-internal-string high-voltage-withstanding thin film power capacitor

A power capacitor and high withstand voltage technology, which is applied in the field of multi-internal series high withstand voltage film power capacitors, can solve problems such as damage, danger, and influence of surrounding components of intelligent power capacitors, achieve rapid heat transfer, protect safety, and reduce serial interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

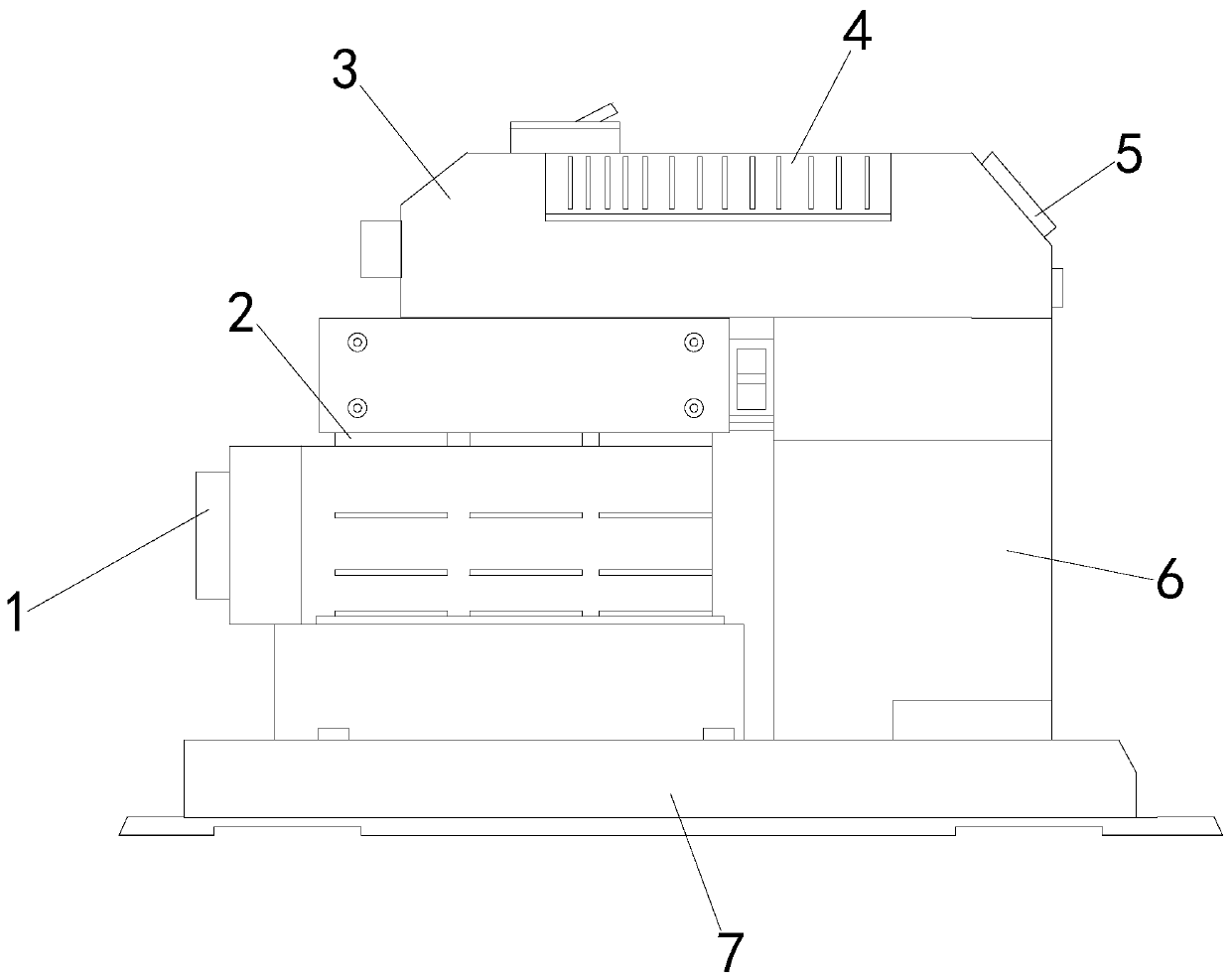

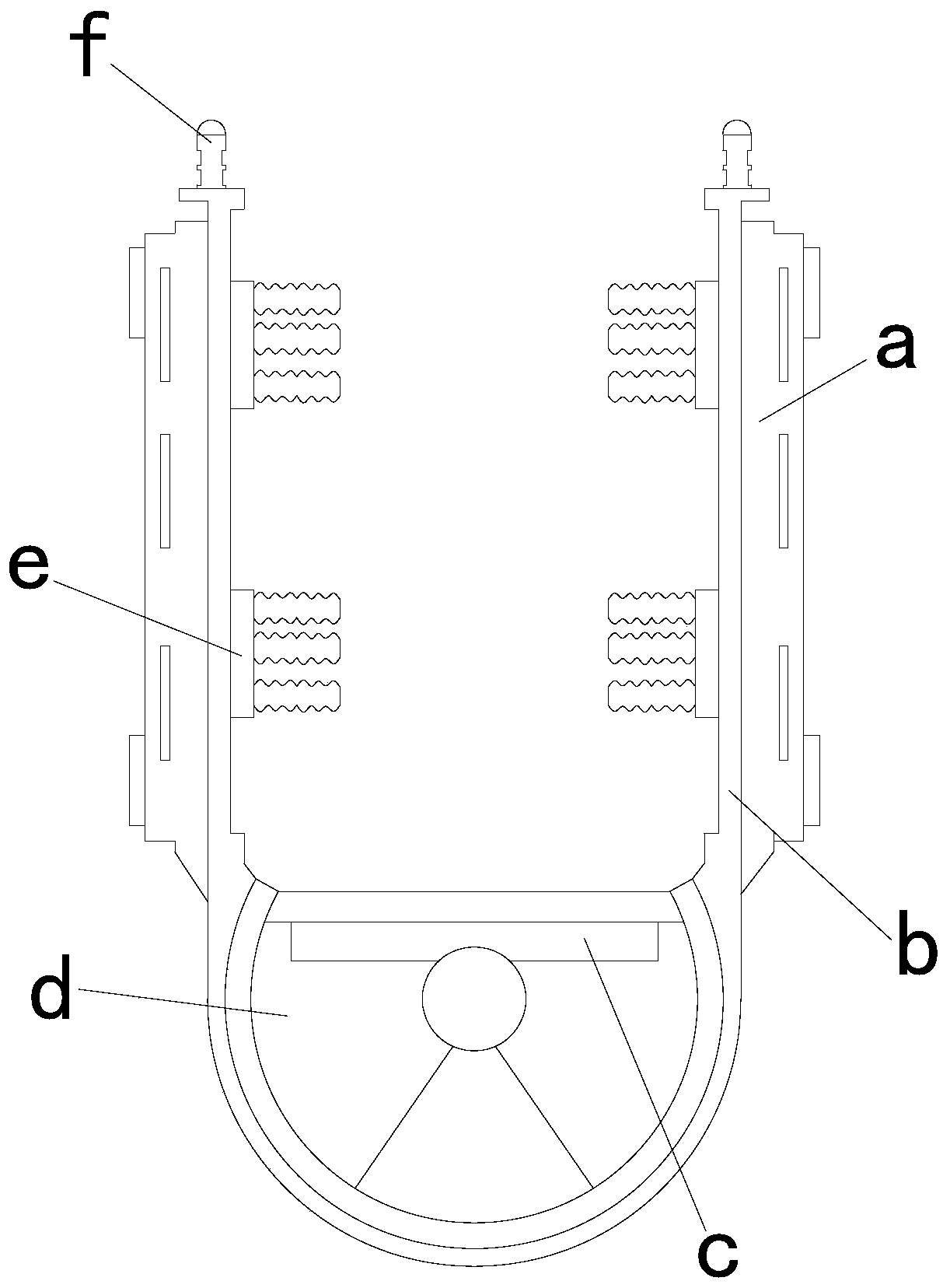

[0025] see Figure 1-Figure 2 , the present invention provides a multi-inner series high voltage film power capacitor technical solution: its structure includes: a nested board body 1, a capacitor tube group 2, a wiring compartment 3, a radiator 4, a controller 5, a converter 6, a lock seat 7, the radiator 4 is installed above the wiring compartment 3 and locked with the wiring compartment 3, the upper right of the wiring compartment 3 is provided with a controller 5, the controller 5 is electrically connected to the wiring compartment 3, and the wiring A converter 6 is arranged below the warehouse 3, and the left end of the converter 6 is provided with a capacitor tube group 2, and the capacitor tube group 2 is electrically connected to the converter 6, and a nested board body 1 is arranged on the outside of the capacitor tube group 2, The nested plate body 1 is fastened to the capacitor tube group 2, and the nested plate body 1 includes a composite layer device a, a stress f...

no. 2 example

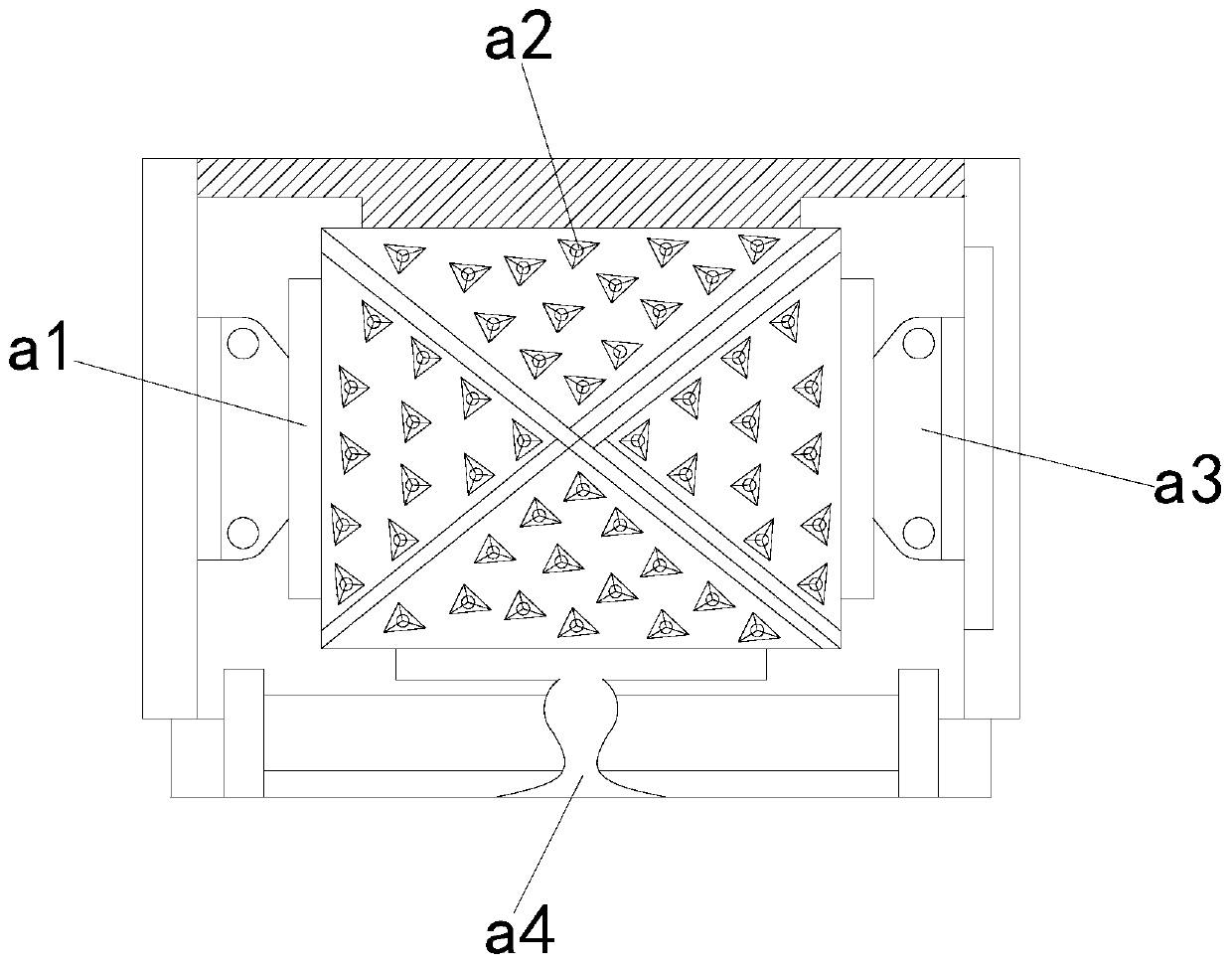

[0028] see Figure 3-Figure 5 , the present invention provides a multi-inner series high voltage film power capacitor technical solution: its structure includes: the composite layer device a includes an outer plate device a1, an inner layer plate a2, a fixed joint shaft a3, and a mounting plate a4. The inner plate a2 is installed on the inner side of the outer plate device a1 and is in clearance fit with the outer plate device a1. The side of the inner plate a2 is provided with a fixed joint shaft a3, and the fixed joint shaft a3 is buckled with the inner plate a2. The inner board a2 is arranged on the side of the installation board a4.

[0029] The outer plate device a1 includes a buffer bar a11, a triangular plate a12, a heat dissipation groove a13, a support piece a14, and a spacer bar set a15. The upper end of a12 is provided with a spacer bar group a15, and the spacer bar group a15 is locked with the triangular plate a12, the inner side of the triangular plate a12 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com