Printed antenna production process

A production process and technology for printing antennas, applied in the field of wireless communication, can solve the problems of unstable antenna performance, high product scrap rate, and large equipment investment, saving man-hours and equipment occupancy, reducing process difficulty, and small equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

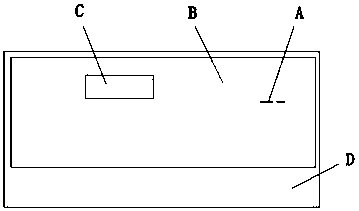

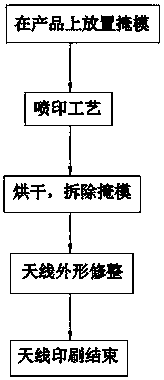

[0014] see Figure 1-Figure 2 As shown, the technical solution adopted in this specific embodiment is: a production process of a printed antenna includes the following steps: Step 1, according to the designed antenna pattern and the structure of the product, a mask is made to cover the non-printing area to prevent the printing In the process, other areas are contaminated; step 2, the positioning pattern for machine vision positioning is pre-designed on the mask, and accurate positioning can be achieved during the printing process; step 3, the mask coverage area adjusts the printing area according to actual needs The graphics and size are slightly adjusted to meet the requirements of the follow-up process; step 4, use a special printing device to execute the spraying operation of the pre-prepared special printing paste according to the pre-set printing action in the program. Printing operation; Step 5, after the jet printing operation, perform mask removal and drying operations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com