High-humidity efficient pulverizer

A pulverizer, high-efficiency technology, applied in the direction of grain processing, etc., can solve the problems of wet material crushing output impact, material can not be discharged, material sticking to the wall, etc., to achieve easy operation and use, assembly and maintenance, increase crushing output, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

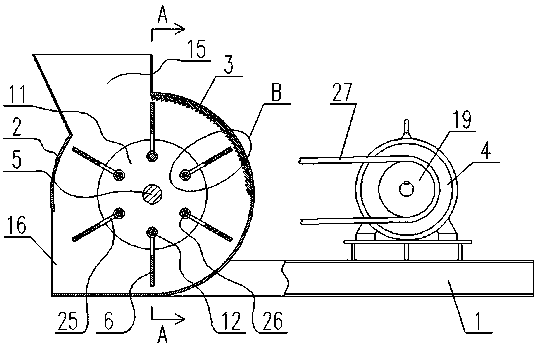

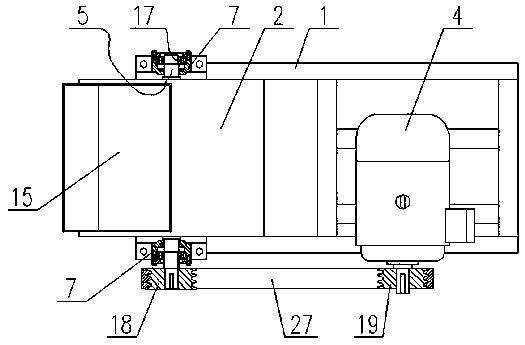

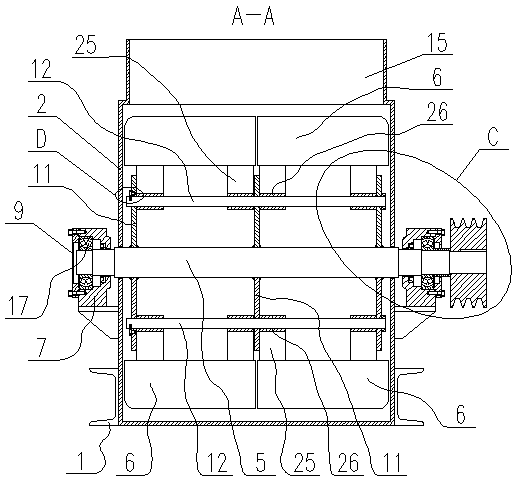

[0021] Depend on figure 1 , figure 2 and image 3 As shown, the high-humidity and high-efficiency pulverizer includes a frame 1, a shell 2, a setback plate 3, a motor 4, a main shaft 5, a hammer 6, a pair of bearing seats 7, a pair of oil seals 8, and a non-porous bearing Cover 9, perforated bearing cover 10, spacer sleeve 28, bracket 11, cylinder 12, circlip 13 and bolt 14, the housing 2 and the motor 4 are fixedly installed on the frame 1, on the housing 2 A material inlet 15 and a material outlet 16 are provided, the material inlet 15 is located at the upper part of the housing 2, the material outlet 16 is located at the lower side of the housing 2, and is located at the tangent line of the bottom side wall of the housing 2 direction. Described main shaft 5 is movably installed in housing 2, and described motor 4 is connected with the transmission of main shaft 5, and the installation mode of main shaft 5 in housing 2 and the transmission connection relation with motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com