Staggered unloading device for cargo tanks and unloading method thereof

A technology of unloading device and cargo box, which is applied in the field of wrong unloading device between cargo boxes, which can solve the problems that affect the unloading efficiency of mushroom stacking powder, the transport chain plate is not durable, increase the maintenance cost, etc., and achieve good unloading effect , Easy and fast installation, high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

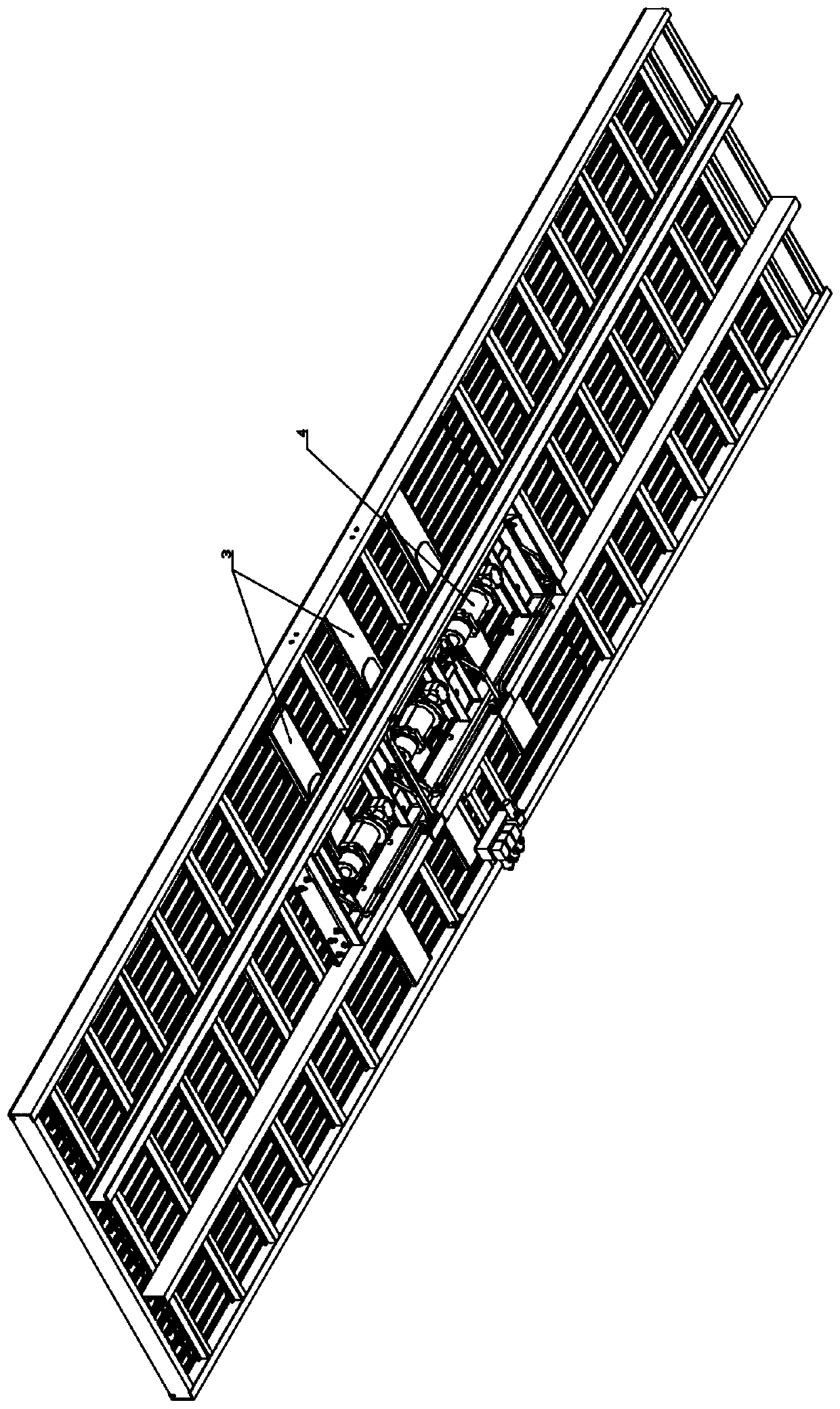

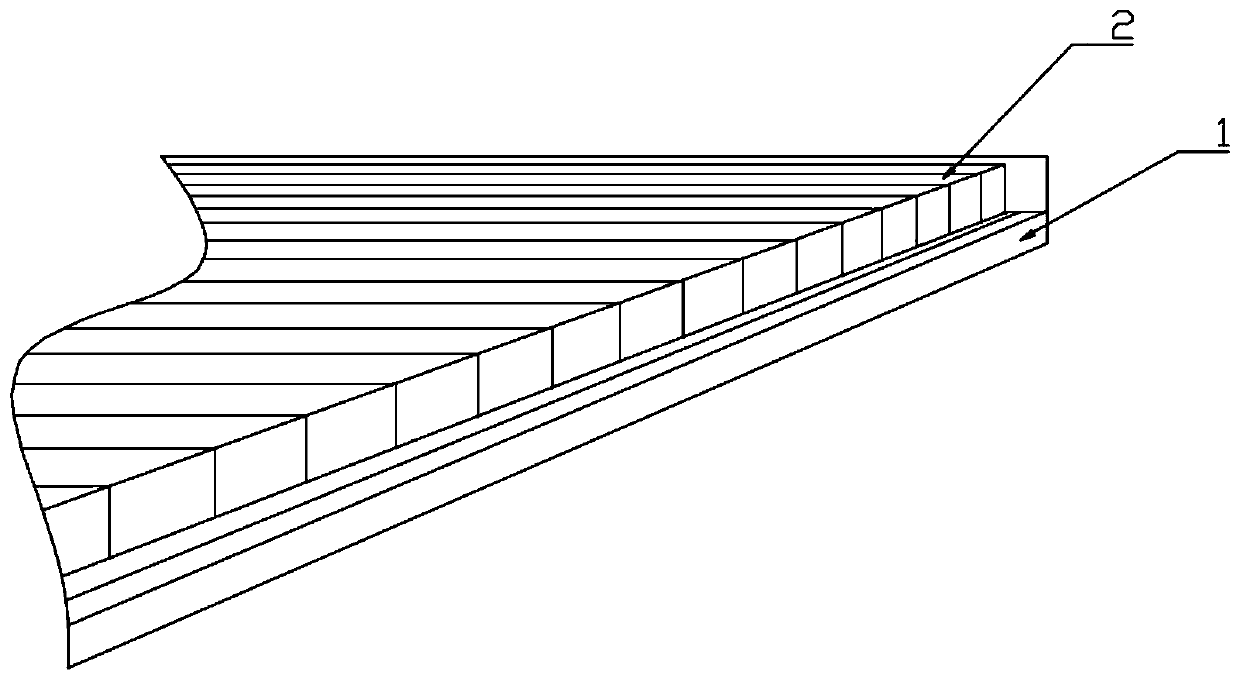

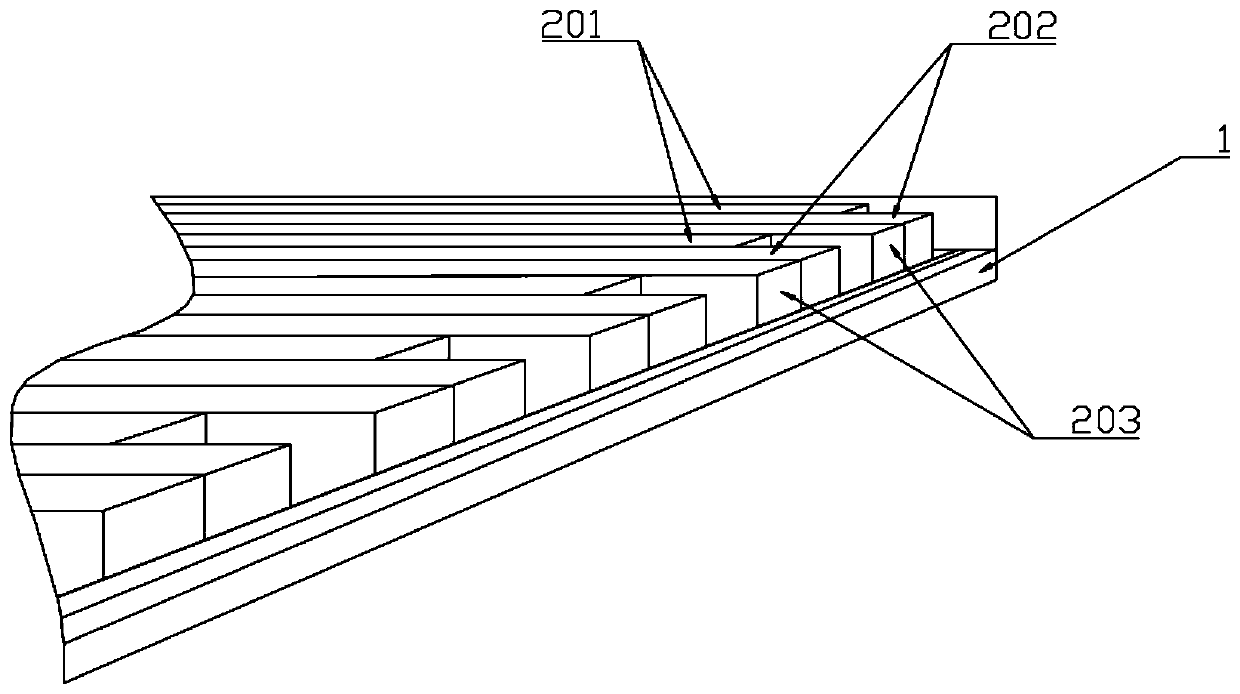

[0030] refer to figure 1 , a kind of staggered unloading device between cargo boxes, comprising a support bracket 1 fixedly installed at the bottom of the cargo box of a truck, 24 unloading plates 2 are arranged on the support end surface of the support bracket 1, each unloading plate The specifications of the plate 2 are 11.9m in length and 0.15m in width. The unloading plate 2 is long and the outer end of the unloading plate 2 is set towards the discharge port of the container, and the adjacent unloading plates 2 are arranged close to each other. A loading platform is formed, and an interstitial drive mechanism used in conjunction with the unloading plate 2 is installed on the support frame 1 or the frame of the truck;

[0031] refer to figure 2 , the interstitial drive mechanism includes three transmission slides 3 and drivers used in conjunction with the transmission slides 3, the transmission slides 3 are slidably mounted on the support bracket 1, and the drivers are fi...

Embodiment 2

[0047] A kind of unloading method that adopts the wrong unloading device between cargo boxes described in embodiment 1 to carry out unloading, its steps are as follows,

[0048] (1) Once, all the unloading plates with materials move forward for a distance under the action of the driver, and drive the materials to move forward for a distance as a whole;

[0049] (2) One time, all the unloading plates in a single interstitial unloading unit retreat for one stroke under the action of the driver, and the material as a whole does not retract with the retreat of the unloading plate;

[0050] (3) Once, all the unloading plates in the second interstitial unloading unit retreat for a stroke under the action of the driver, and the material as a whole does not retract with the retreat of the unloading plates;

[0051] (4) One time, all the unloading plates in the N-th spaced unloading unit move back a stroke under the action of the driver, and the material as a whole does not retract wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com