A kind of concrete cementitious material conditioner and preparation method thereof

A cementitious material and concrete technology, which is applied in the field of concrete cementitious material regulator and its preparation, can solve the problem of matching limitation of large-scale application and promotion of cementitious reducer, achieve good water retention performance, high specific surface area, and avoid segregation and secretion water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

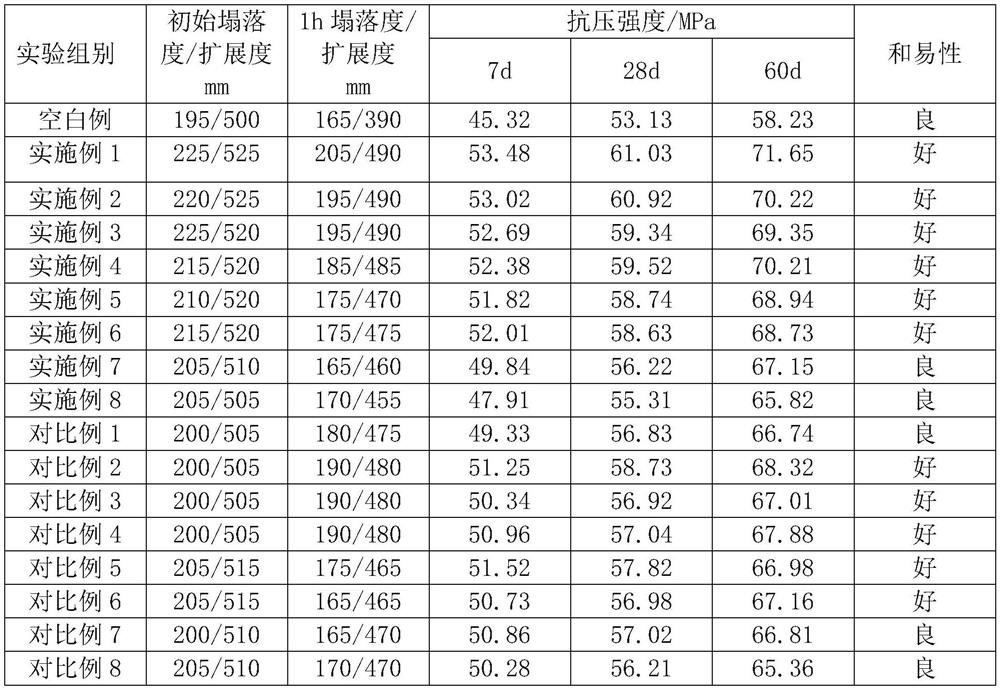

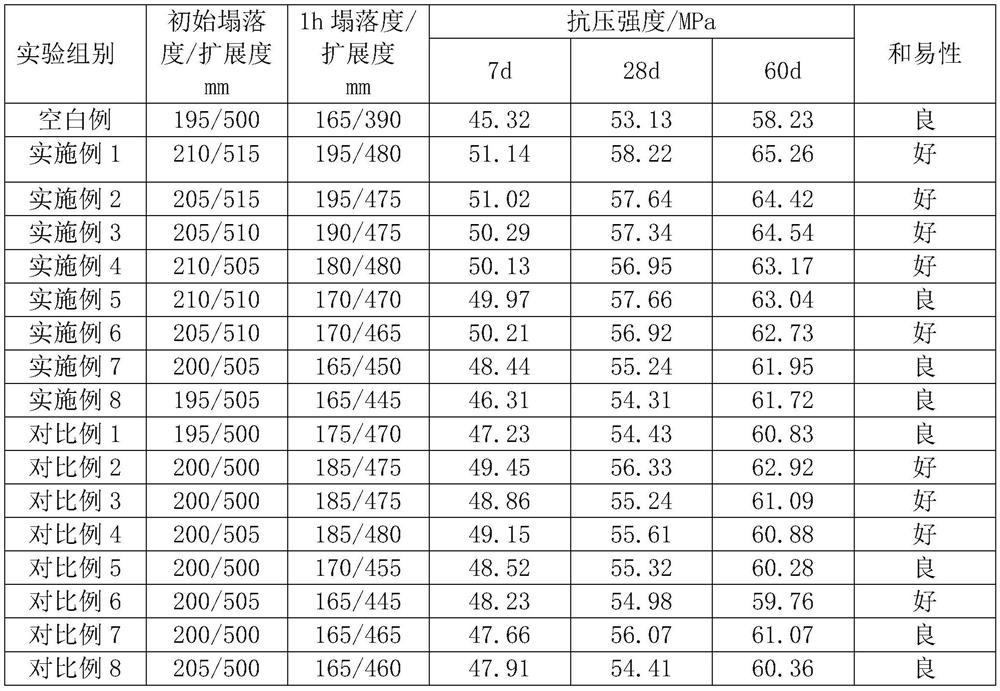

Examples

Embodiment 1

[0032] Embodiment 1 is a concrete cementitious material conditioner disclosed by the present invention and its preparation method. The conditioner is based on 1000kg and includes the following components in parts by weight: 500kg of mixed alcohol amine grafts, 100kg of sodium thiocyanate, Zero-water sodium metasilicate 50kg, tert-butylphenol 55kg and crospovidone 4.5kg, the balance is water;

[0033] Mixed alcohol amine grafts include triethanolamine grafts, triisopropanolamine grafts and diethanolamine grafts;

[0034] The mass fraction ratio of the triethanolamine graft, the triisopropanolamine graft and the diethanolamine graft is 1:1.125:1; the graft is hydroxypropyl methylcellulose;

[0035] The preparation method of regulator comprises the following steps:

[0036] S1. First add water to the mixing tank, then add zero-water sodium metasilicate and sodium thiocyanate, and fully stir the two components until they are completely dissolved in water;

[0037] S2. Add trieth...

Embodiment 2

[0039] Embodiment 2 is a concrete cementitious material conditioner disclosed by the present invention and its preparation method. The conditioner is based on 1000kg and includes the following components in parts by weight: 475kg of mixed alcohol amine grafts, 80kg of sodium thiocyanate, Zero water sodium metasilicate 40kg, tert-butylphenol 70kg and cross-linked povidone 6kg, the balance is water;

[0040] Mixed alcohol amine grafts include triethanolamine grafts, triisopropanolamine grafts and diethanolamine grafts;

[0041] The mass fraction ratio of the triethanolamine graft, the triisopropanolamine graft and the diethanolamine graft is 1:1.125:1; the graft is hydroxypropyl methylcellulose;

[0042] The preparation method of regulator comprises the following steps:

[0043] S1. First add water to the mixing tank, then add zero-water sodium metasilicate and sodium thiocyanate, and fully stir the two components until they are completely dissolved in water;

[0044] S2. Add ...

Embodiment 3

[0046]Embodiment 3 is a concrete cementitious material conditioner disclosed by the present invention and its preparation method. The conditioner is based on 1000kg and includes the following components in parts by weight: 520kg of mixed alcohol amine grafts, 120kg of sodium thiocyanate, Zero water sodium metasilicate 60kg, tert-butylphenol 40kg and crospovidone 3kg, the balance is water;

[0047] Mixed alcohol amine grafts include triethanolamine grafts, triisopropanolamine grafts and diethanolamine grafts;

[0048] The mass fraction ratio of the triethanolamine graft, the triisopropanolamine graft and the diethanolamine graft is 1:1.125:1; the graft is hydroxypropyl methylcellulose;

[0049] The preparation method of regulator comprises the following steps:

[0050] S1. First add water to the mixing tank, then add zero-water sodium metasilicate and sodium thiocyanate, and fully stir the two components until they are completely dissolved in water;

[0051] S2. Add triethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com