Working device of wheel type telescopic arm loader

A technology of working device and telescopic arm, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. Stable overturning and other problems, achieve good lifting and translation performance and automatic leveling, reasonable structure, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

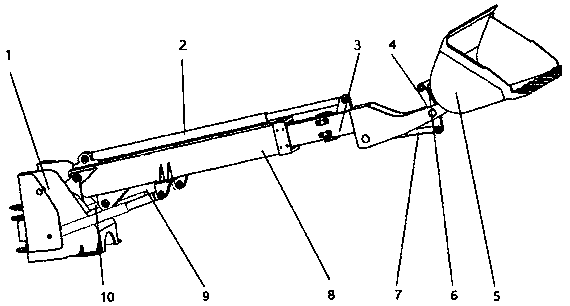

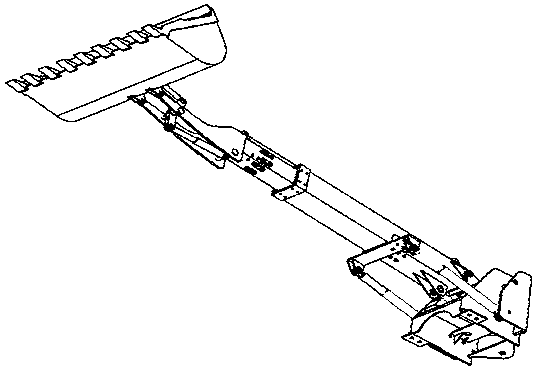

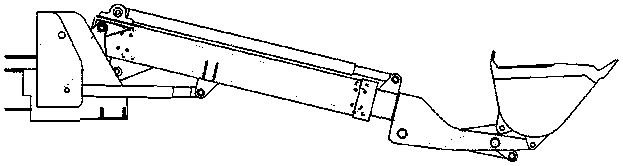

[0015] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , the patent of the present invention is a working device of a wheeled telescopic arm loader, which consists of a front frame (1), a telescopic oil cylinder (2), a telescopic arm II stage arm (3), a rocker arm (4), and a bucket (5) , bucket connecting rod (6), bucket overturning oil cylinder (7), telescopic arm I stage arm (8), booster oil cylinder (9), follow-up oil cylinder (10).

[0016] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , the working device of the wheeled telescopic arm loader has two hinge points on both sides of the front frame (1) for installing the booster cylinder (9), and a hinge point connected to the first-stage arm (8) of the telescopic arm is arranged on the top. point, the hinge point for installing the follower cylinder (10) is arranged below, and the front frame (1) is connected with the rear frame of the car body; the working device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com