Quakeproof passive house wall foundation

A base and house wall technology, applied in the field of passive houses, can solve the problems of inconvenient wall maintenance and replacement, and achieve the effects of easy promotion, beneficial technical effects, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

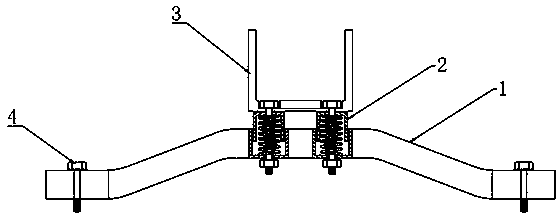

[0037] see Figure 1-5 , this implementation provides a wall base for an anti-seismic passive house, including a base 1, an anti-seismic component 2 and a wall fixing groove 3, wherein:

[0038] The base 1 is a bridge-shaped structure, including anchor ends at both ends, a mounting plate located in the middle and higher than the anchor ends, and a curved support portion connecting the anchor ends and the mounting plate, and the anchor ends are provided with keyway-shaped screw holes 11; The keyway-shaped screw hole 11 provides a buffer space for the base to vibrate up and down;

[0039] The anti-shock assembly 2 is located between the base and the wall fixing groove, and is composed of a lower cavity 21, an upper cavity 23, a shock absorbing spring 22, a screw rod 24, and a fastening nut 25. The lower cavity 21 is fixed on the mounting plate through or integrally formed with the mounting plate, the upper cavity 23 is fastened in the lower cavity 21, the shock absorbing spring...

Embodiment 2

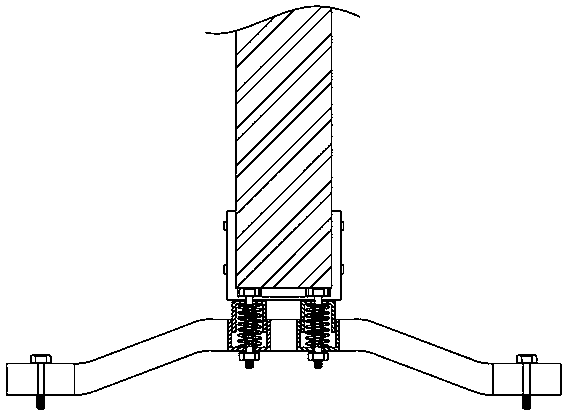

[0044] see Figure 6-8 , this implementation provides a wall base for an anti-seismic passive house, including a base 1, an anti-seismic component 2 and a wall fixing groove 3, wherein:

[0045] The base 1 is a bridge-shaped structure, including anchor ends at both ends, a mounting plate located in the middle and higher than the anchor ends, and a curved support portion connecting the anchor ends and the mounting plate, and the anchor ends are provided with keyway-shaped screw holes 11;

[0046]The anti-shock assembly 2 is located between the base and the wall fixing groove, and is composed of a lower cavity 21, an upper cavity 23, a damping spring 22, a screw 24, and a fastening nut 25. The lower cavity 21 is fixed on the mounting plate through The inside of the upper cavity 23 is fastened in the lower cavity 21, the shock absorbing spring 22 is located inside the upper cavity 23 and the lower cavity 21, and is arranged in two around the screw rod 24; the screw rod 24 Throu...

Embodiment 3

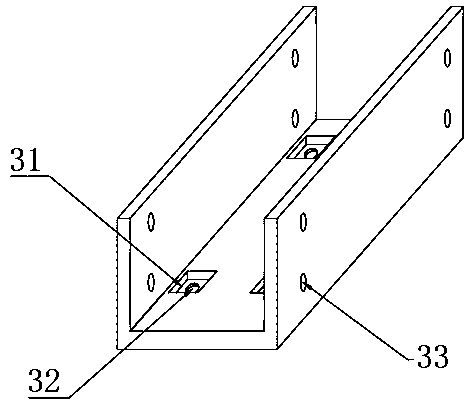

[0051] see Figure 9-Figure 10 , this implementation provides a wall base for an anti-seismic passive house, including a base 1, an anti-seismic component 2 and a wall fixing groove 3, wherein:

[0052] The base 1 The base 1 is two bridge-shaped structures fixedly connected side by side, including four anchor ends at the bottom, an integral structure mounting plate located in the middle and higher than the anchor ends, connecting the anchor ends and The curved support part of the mounting plate, the said anchor end is provided with a keyway-shaped screw hole 11;

[0053] The anti-shock assembly 2 is located between the base and the wall fixing groove, and is composed of a lower cavity 21, an upper cavity 23, a damping spring 22, a screw 24, and a fastening nut 25. The lower cavity 21 is fixed on the mounting plate through The inside of the upper cavity 23 is fastened in the lower cavity 21, the damping spring 22 is located inside the upper cavity 23 and the lower cavity 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com