A polyurethane board with sound insulation function and its preparation process

A technology of polyurethane board and polyurethane layer, which is applied in the direction of sound insulation, roofing with flat/curved panels, synthetic resin layered products, etc., and can solve problems such as poor sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

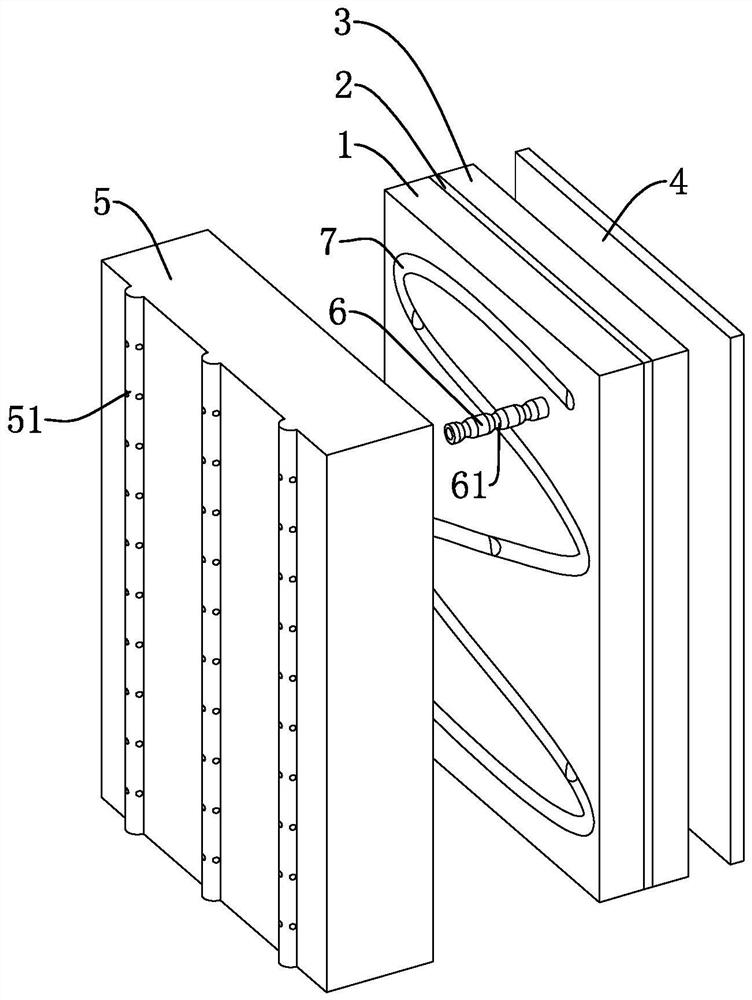

[0036] Example: a polyurethane board with sound insulation function, such as figure 1 As shown, it includes the substrate 4, the second polyurethane layer 3, the damping layer 2, and the first polyurethane layer 1 arranged in sequence, and the second polyurethane layer 3, the damping layer 2, and the first polyurethane layer 1 are covered with the substrate 4. The housing 5 inside it.

[0037] Both the first polyurethane layer 1 and the second polyurethane layer 3 are made of PU material. Polyurethane refers to a large class of polymers containing more carbamate group characteristic structures on the main molecular chain. It is a kind of polymer between plastics and plastics. The polymer material between rubbers has a large elongation, a wide range of hardness, a wide range of formula adjustment, and excellent wear resistance and mechanical properties.

[0038] The damping layer 2 is a self-adhesive modified asphalt board. As a viscoelastic material, the damping layer 2 is at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com