A hydraulic vibration system

An oscillating system and hydraulic technology, applied in vibration generating devices, fluid pressure actuating devices, wellbore/well components, etc., can solve the problems of difficult processing, limited vibration impact momentum, high cost, etc., and reduce the number of trips , high oscillation frequency, and the effect of reducing drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further described:

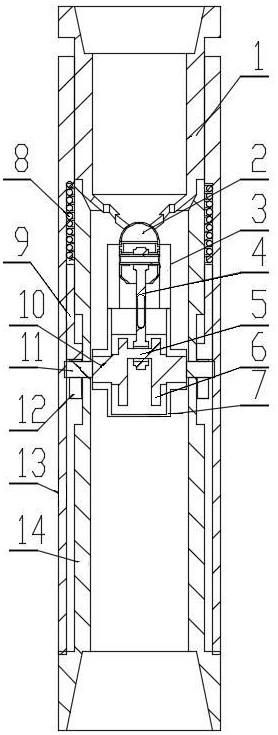

[0034] Such as figure 1 As shown, this hydraulic oscillation system includes an upper sleeve 1, a piston 2, an upper cylinder liner 3, a lower cylinder liner 7, a crankshaft 5, a connecting rod 4, a balance flywheel 6, an outer edge shaft 10, a camshaft 11, a cam 12, Push rod 9, ring wall spring 8, oscillating outer sleeve 13, lower connecting sleeve 14, the lower connecting sleeve 14 is threadedly connected to the lower end of the upper connecting sleeve 1 to form an inner cylinder, the lower end of the lower connecting sleeve 14 has an annular step outside, and the oscillating outer sleeve 13 surrounds it Out of the tube and freely fall on the annular step, the oscillating jacket 13 is socketed with the entire internal system; the oscillating jacket 13 forms an annular space with the lower connecting tube 14 through the inner step set on the upper part, and the upper por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com