Mined-out area air leakage field optimization based coal and gas symbiotic disaster control method

A technology of goaf and air leakage, which is applied in the direction of gas emission, design optimization/simulation, dust prevention, etc., can solve problems such as unconsidered goaf flow field, increased risk of spontaneous combustion of coal, spontaneous combustion of residual coal, etc., to ensure gas protection Drainage effect, realization of coal and gas co-occurrence disaster prevention, and optimization effect of air leakage field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below.

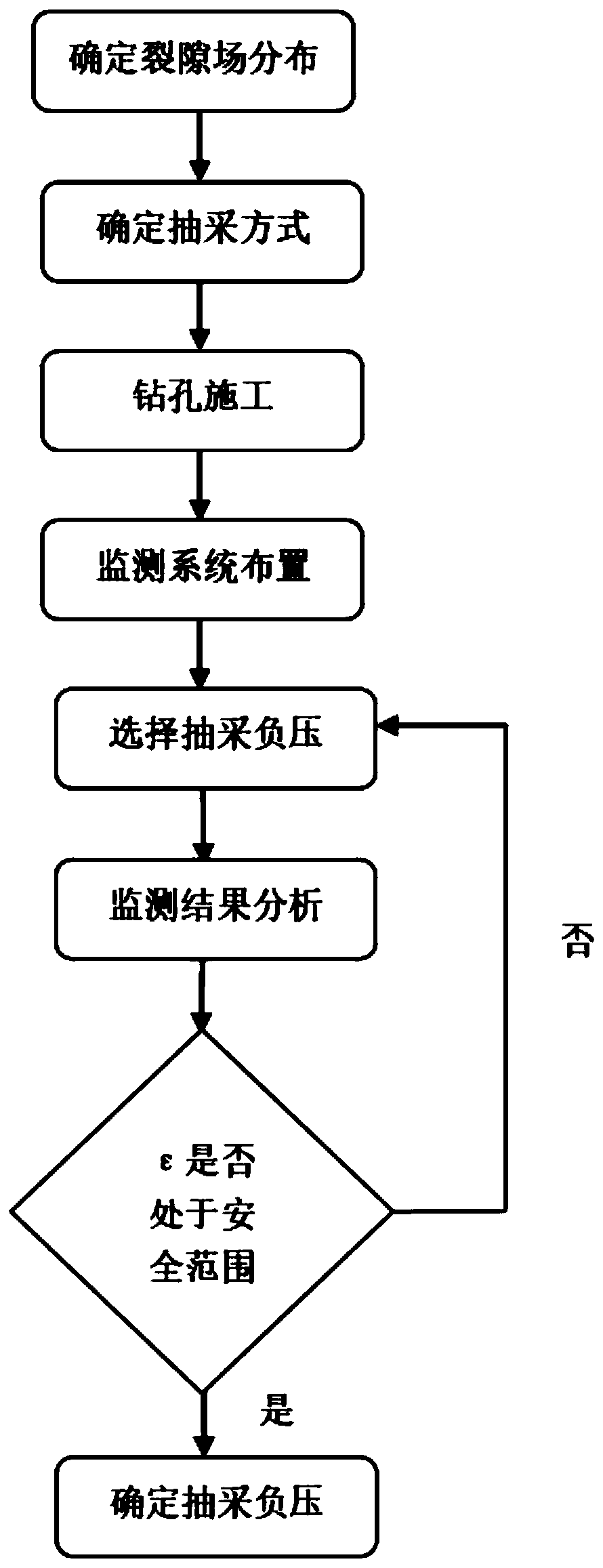

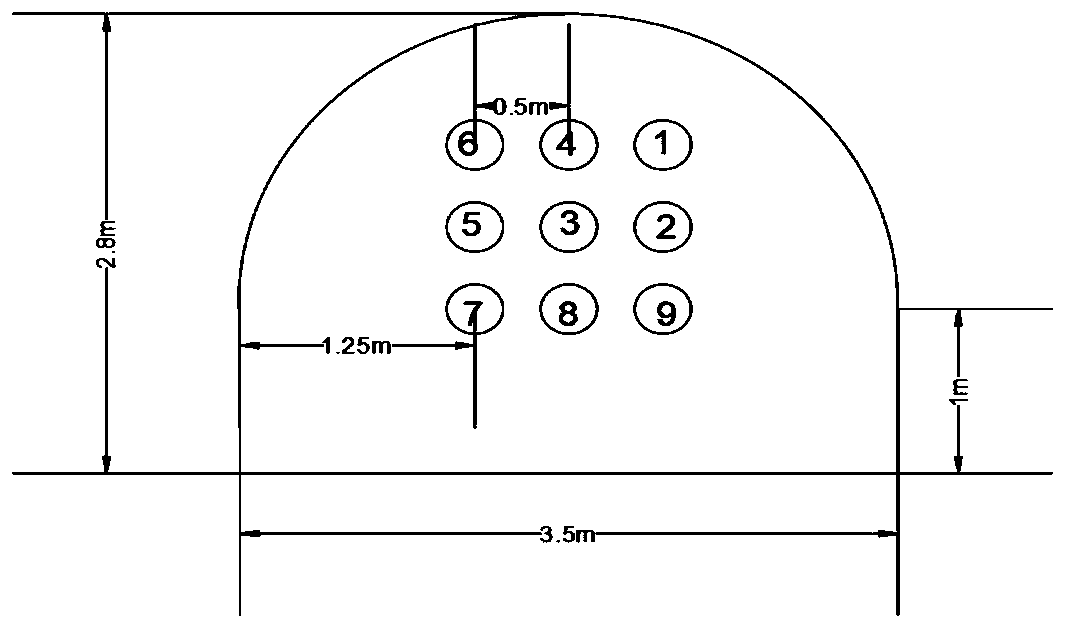

[0040] Such as Figure 1 to Figure 4 Shown, concrete steps of the present invention are:

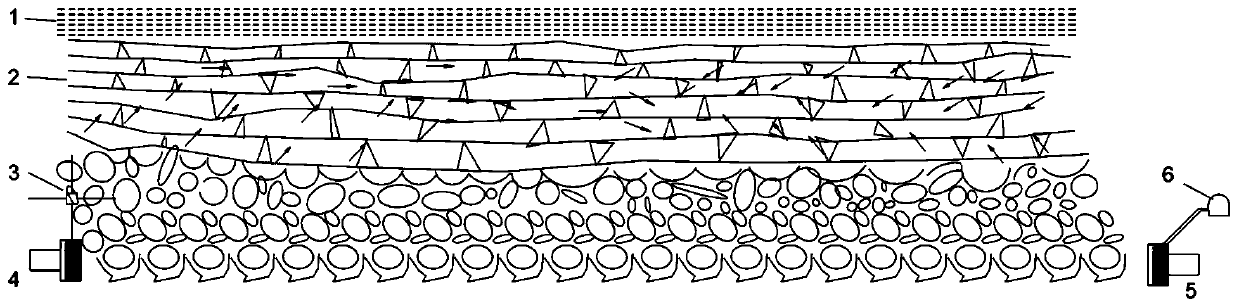

[0041] A. Determine the distribution range of the goaf and its overlying fissure field, and then determine the height range of the drilling position: the height range of the fissure zone 2 of the coal seam in the goaf is calculated by the following formula (1), and the overlying area of the goaf The height range of the fissure zone of the rock formation is obtained through known geological data; since the drilling position is located within the height range of the fissure zone 2 of the goaf 8 coal seam, formula (2) is used to obtain it;

[0042]

[0043]

[0044] Among them, ∑M is the coal seam thickness, H F is the height of fissure zone 2 of coal seam 8 in goaf, H D is the height of the drilling position;

[0045] B. Determine a reasonable gas drainage method according to the distribution range of the fracture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com